Method for microwave induced catalytic degradation of triphenyl methane dye waste water

A technology of triphenylmethane and induced catalysis, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of difficult light penetration, affecting degradation effect, and low photon quantum efficiency, so as to overcome the problem of light quantum The effect of low efficiency, overcoming low light utilization rate, and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare 0.8M Ni(NO 3 ) 2 ·6H 2 O solution, 1.6M NaOH solution and 12wt% NaClO solution are ready for use. First take 50mL Ni(NO 3 ) 2 ·6H 2 O solution was added dropwise to 50mL NaOH solution (molar ratio 1:2) to obtain Ni(OH) 2 . Subsequently, 100 mL of NaClO solution was added dropwise to the above-prepared solution with stirring, and the solution gradually changed from green to black precipitate. The above reaction was carried out in a water bath at a temperature of 70° C., and then the above reaction solution was placed in an ultrasonic device for 15 minutes of sonication. The resulting precipitate was suction-filtered and washed several times with deionized water, then collected and transferred to a muffle furnace for drying at 110°C for 20 hours, and finally calcined at 300°C for 2 hours. The resulting black solid is the NiO catalyst, which is stored in a desiccator. Characterize the catalyst. After the reaction is finished, the catalyst is collected, an...

Embodiment 2

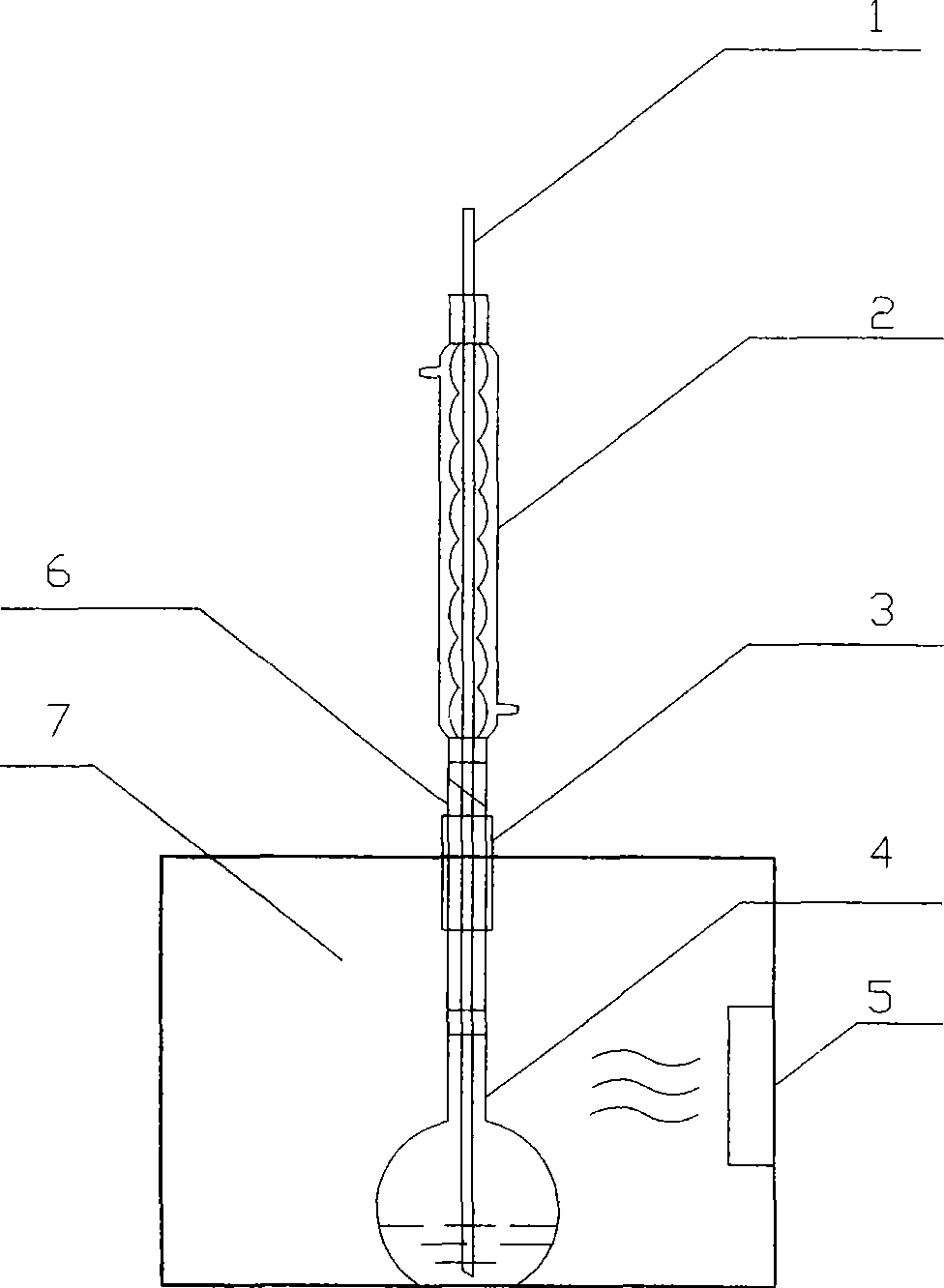

[0028] Prepare a 100mg / L malachite green aqueous solution to simulate dye wastewater, and measure 50mL of the aqueous solution into a reaction bottle. The reaction was then placed in a microwave oven. 1 is the condenser tube, 2

[0029] Modify the microwave power to 600w household microwave oven, such as figure 1As shown, wherein the aeration pipe 1, the condenser pipe 2, the aluminum casing 3, the flat-bottomed flask 4, the microwave generator 5, the connecting pipe 6, and the microwave cavity 7. Adjust the microwave power, connect the condensed water, and continue to aerate the reaction liquid, rotate the microwave time gear, the microwave oven will start to work, start timing at this time, and the reaction time is about 5 minutes. After the reaction, cool and centrifuge to collect the reaction solution. The following two reaction systems were set up to measure the change of malachite green concentration with the reaction time.

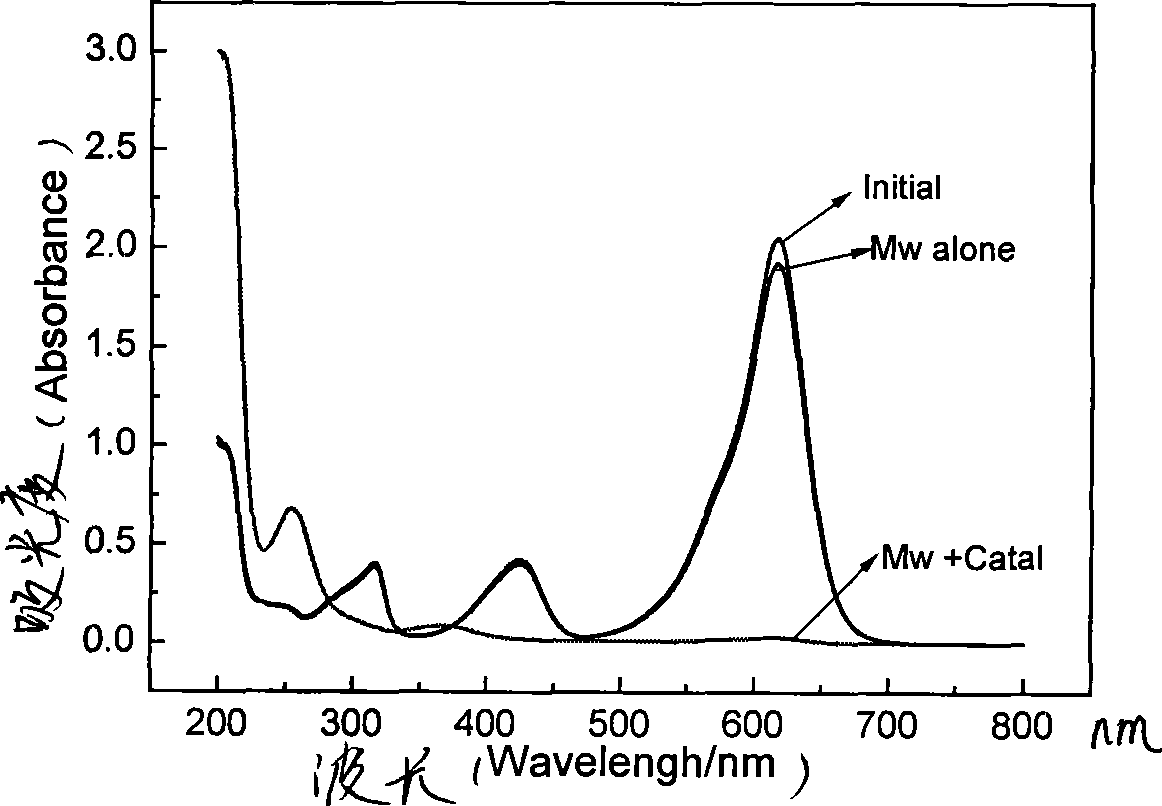

[0030] 1) The reaction is only carried ou...

Embodiment 3

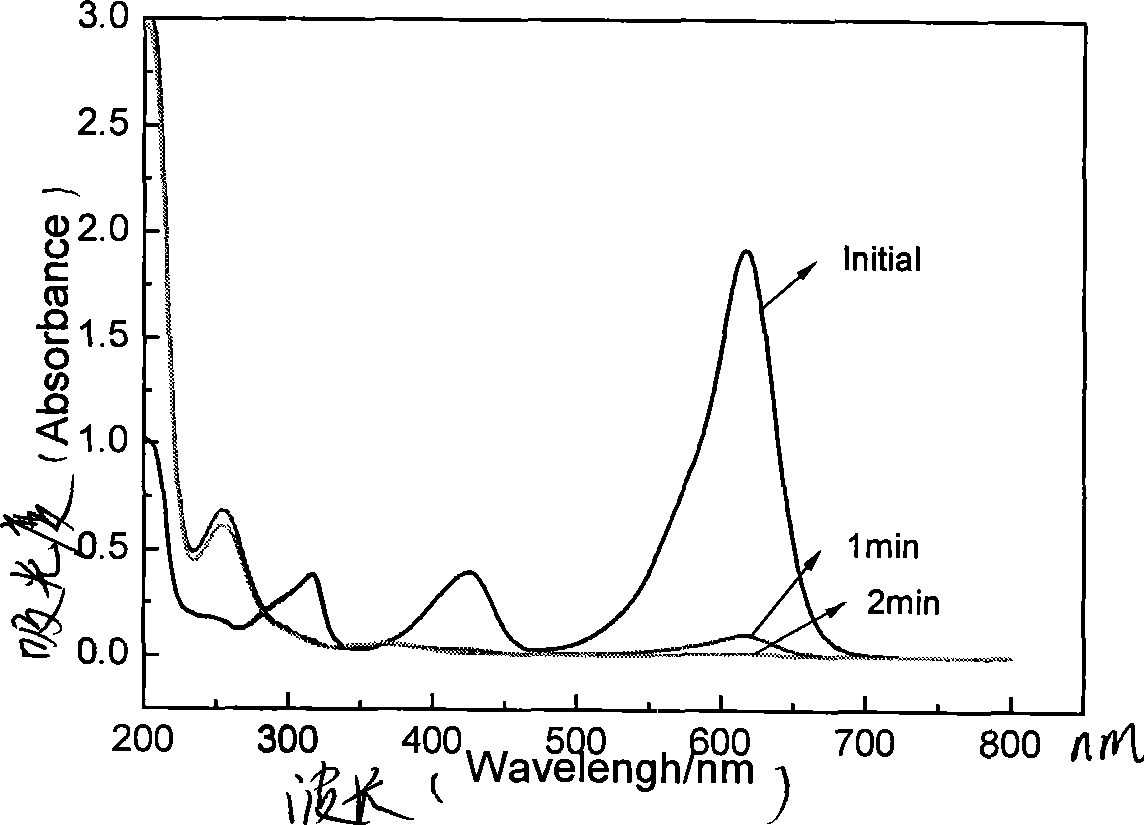

[0034] Prepare a 10mg / L malachite green aqueous solution to simulate dye wastewater, and measure 50mL of the dye solution into a reaction bottle. Weigh 20 mg of NiO (0.4 mg / L) catalyst into the above reaction solution, and then place it in a microwave oven for reaction. Adjust the microwave power, connect the condensed water, and continuously aerate the reaction liquid, rotate the microwave time gear, the microwave oven starts to work, and the timer starts at this time. After the reaction, cool and centrifuge to collect the reaction solution. The change of malachite green concentration with the reaction time was measured. The experimental results showed that the concentration of malachite green decreased by 99.7% within 2 minutes, and the removal rate of TOC reached 82.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com