Production method of chloromethyl ethyl ether

A technology of chloromethyl ethyl ether and its production method, which is applied in ether preparation, organic chemistry, etc., can solve the problems of cumbersome post-processing and high production cost, and achieve the effects of complete reaction, environment improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

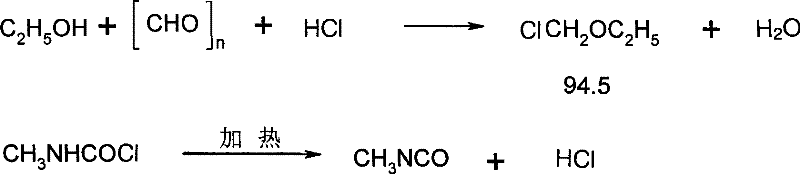

Method used

Image

Examples

Embodiment 1

[0018] Put 320g of paraformaldehyde and 460g of absolute ethanol into a 1000ml reaction bottle, start stirring, control the temperature between 0-20°C, and pass in hydrogen chloride, a by-product of the production of methyl isocyanate, when the ethanol content is lower than 0.5% When standing and stratifying, the bottom layer of chloromethyl ethyl ether has a weight of 928g, a content of 99.1%, and a yield of 97.3%. In terms of ethanol, it can directly carry out the synthesis of compounds such as acetochlor; the formaldehyde in the upper aqueous solution can be recycled and used mechanically.

Embodiment 2

[0022] 320g of paraformaldehyde and 485g of 95% ethanol (industrial grade) are dropped into a 1000 ml reaction bottle, and the stirring is started, and the temperature is controlled between 0-20°C, and the by-product hydrogen chloride produced in the production of methyl isocyanate is introduced, when When the ethanol content is lower than 0.5%, it is left to stand for stratification. The bottom layer of chloromethyl ethyl ether weighs 885g, with a content of 99.1%, and a yield of 92.8%. In terms of ethanol, it can directly carry out the synthesis of compounds such as acetochlor; formaldehyde can be recycled.

Embodiment 3

[0024] Put 865g of 37% formaldehyde aqueous solution and 485g of 95% ethanol into a 1000ml reaction bottle, start stirring, control the temperature between 0-20°C, and pass in hydrogen chloride, a by-product of the production of methyl isocyanate, when the ethanol content When it is lower than 0.5%, it is allowed to stand and separate, the bottom layer of chloromethyl ethyl ether weighs 875g, the content is 98.3%, and the yield is 91.0%. In terms of ethanol, it can directly carry out the synthesis of compounds such as acetochlor, and the formaldehyde in the upper aqueous solution can be recovered apply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com