Scaphium scaphigerum polysaccharide, preparation and use thereof

A kind of fat sea and polysaccharide technology, applied in the field of fat sea polysaccharide and its preparation, can solve the problem of no fat sea polysaccharide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

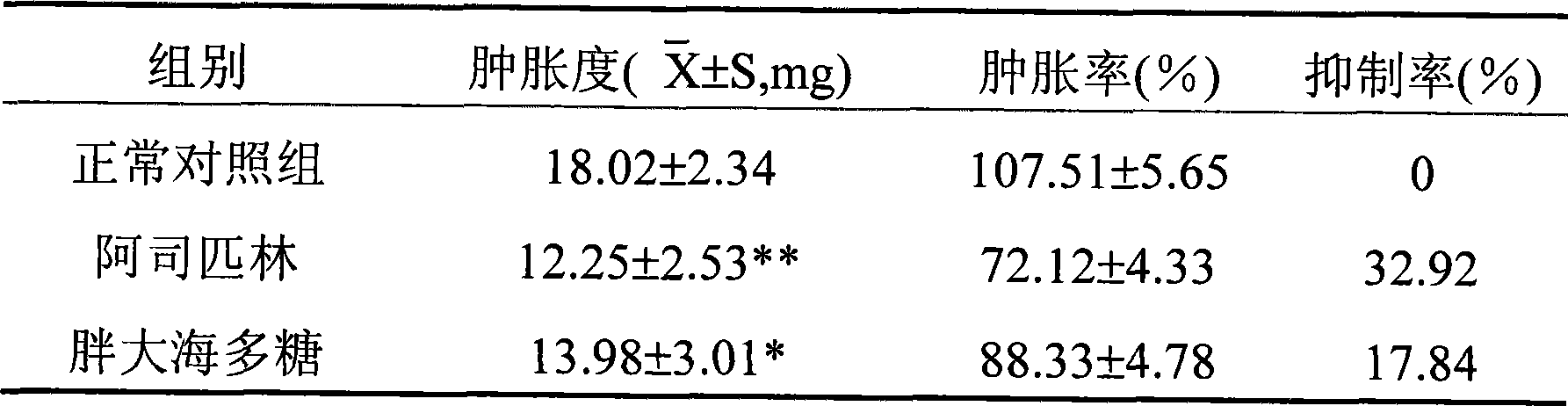

Examples

Embodiment 1

[0018] Crush the non-mildew and dry Pang Hai into powder of 40-50 mesh size; condense and reflux in petroleum ether at 50°C for 2.5 hours, repeat twice for degreasing, and dry the material; dry the degreased dry material at 80 Condensate and reflux in % ethanol for 2.5h, repeat twice to remove small molecular substances such as monosaccharides, polyphenols, oligosaccharides and glycosides and passivate endogenous enzymes, evaporate the solvent on the raw materials; add 75 times the weight of water Soak the pretreated raw materials, select ultrasonic power of 60W, and ultrasonically treat the material for 15 minutes; heat the above-mentioned liquid to 65°C, stir and extract continuously for 1.5 hours, centrifuge at 3500 rpm for 10 minutes in a centrifuge, and the supernatant Suspended swollen gums in the liquid are suction-filtered with 200-mesh nylon cloth, and the sediment and insoluble matter are added with water 25 times the weight of the raw material, extracted in a 65°C wa...

Embodiment 2

[0020] Condensate and reflux Pandahai powder in petroleum ether at 60°C for 2 hours, repeat twice to degrease, and dry the material; condense and reflux the dried material after degreasing in 85% ethanol for 2 hours, repeat twice, and evaporate the solvent on the raw material ; Add 70 times the weight of water to soak the pretreated raw materials, select a power of 50W ultrasonic, and ultrasonically treat the material for 15 minutes; heat the above-mentioned material liquid to 60 ° C, continuously stir and extract for 2.0 hours, and pass it through a centrifuge at 3500 rpm Centrifuge for 10 minutes under the same conditions, and the swollen glue suspended in the supernatant is filtered with 200-mesh nylon cloth. The sediment and insoluble matter are added with water 25 times the weight of the raw material, and extracted in a water bath at 60°C for 1.5 hours, similar to the first time. Centrifugal filtration and nylon cloth suction filtration, combined two suction filtrates; Con...

Embodiment 3

[0022]Condensate Pandahai powder in petroleum ether at 30°C for 3 hours, repeat twice to degrease, and dry the material; condense the dried material after degreasing in 80% ethanol for 3 hours, repeat twice, and evaporate the solvent on the raw material ; Add 80 times the weight of water to soak the pretreated raw materials, select a power of 60W ultrasonic, and ultrasonically treat the material for 10 minutes; heat the above-mentioned material liquid to 55 ° C, continuously stir and extract for 2.0 hours, and pass it through a centrifuge at 3500 rpm Centrifuge for 10 minutes under the same conditions, and the swollen glue suspended in the supernatant is filtered with 200-mesh nylon cloth. The sediment and insoluble matter are added with water 25 times the weight of the raw material, extracted in a water bath at 55°C for 1.5 hours, and carried out similarly to the first The centrifugal filtration and nylon cloth suction filtration, combined the two suction filtrates; concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com