Radio frequency electromagnetic impedance match anti-electromagnetic interference composite coating, preparation and spray coating method

An anti-electromagnetic interference and impedance matching technology, applied in radiation-absorbing coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems affecting the application field of RFID, signal conduction interference and attenuation, and affecting the reliability and accuracy of data reading. and other problems, to achieve the effect of strong anti-electromagnetic signal interference ability, low RFID misreading rate and small reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

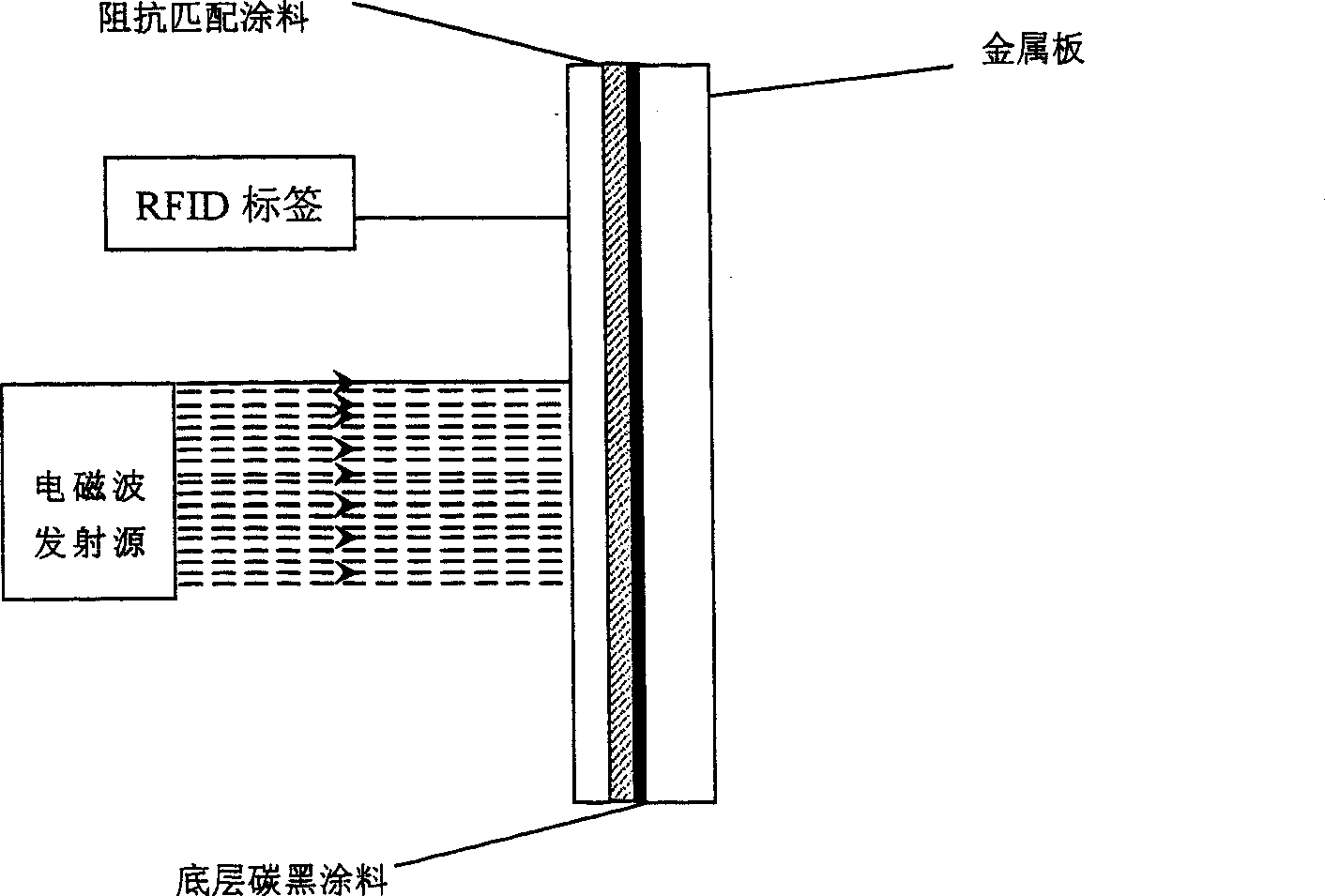

[0103] The wave-absorbing composite coating is composed of impedance matching coating and bottom carbon black coating. The impedance matching coating is composed of 58%-80% resin solution, 8%-40% nano-β silicon carbide, 1%-2% nano-nickel, 1%- 12% polystyrene; the bottom carbon black coating is composed of 75%-85% resin solution and 15%-25% carbon black.

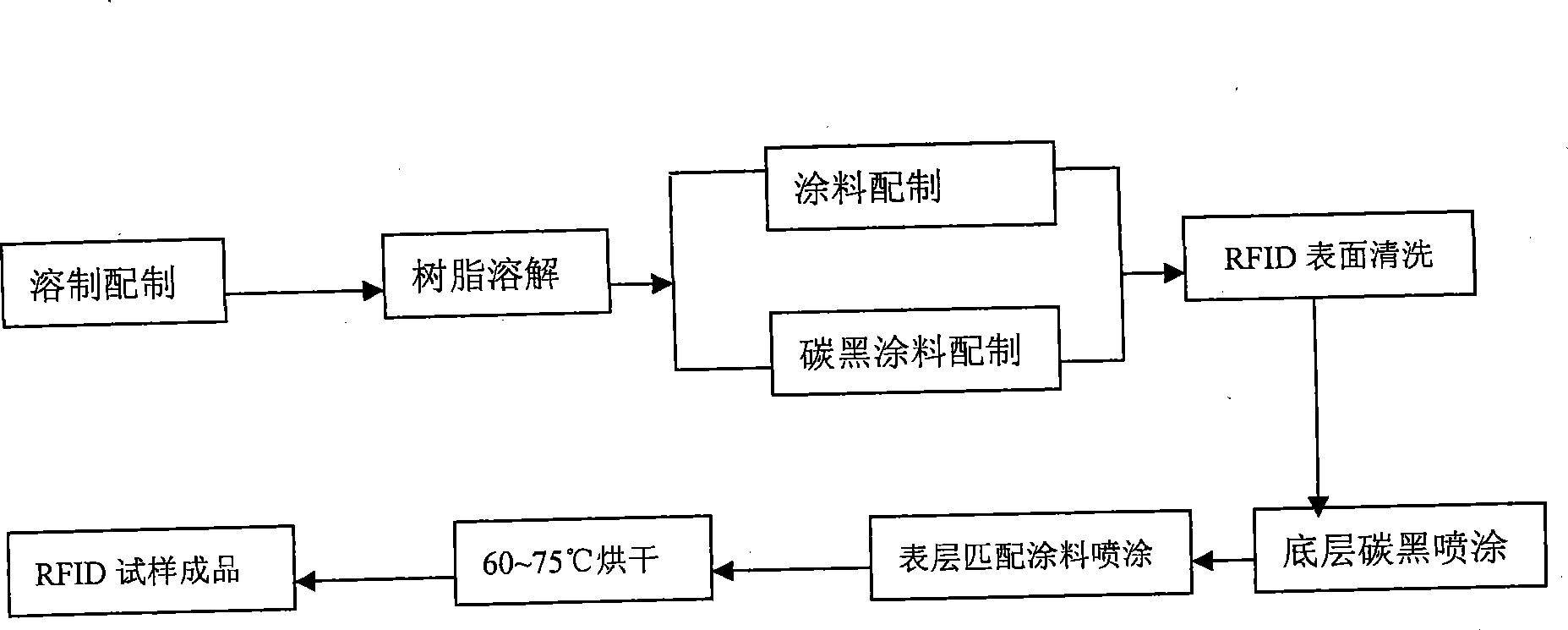

[0104] One, the preparation method of wave-absorbing composite coating, carry out according to the following steps:

[0105] 1) Resin solution preparation:

[0106] ①Solvent preparation:

[0107] The solvent is composed of three substances: methyl isobutyl ketone, ethylene glycol butyl ether, and n-butanol. According to the mass ratio, methyl isobutyl ketone: ethylene glycol butyl ether: n-butanol=3~5:1~3:1 , stirring and mixing the above solvents evenly;

[0108] ② Dissolution of resin

[0109] Add one or two of B133 resin, epoxy resin or acrylic resin to the solvent at a constant speed and slowly, resin:solvent=7~8:2~3,...

Embodiment 2

[0126] The wave-absorbing composite coating is composed of impedance matching coating and bottom carbon black coating, and the impedance matching coating is composed of 60% to 76% resin solution, 10% to 36% nano-β silicon carbide, 1% to 2% nano-nickel, 1 %-10% polystyrene, the bottom carbon black coating is composed of 77%-82% resin solution and 18%-23% carbon black, the preparation method and spraying method are the same as in Example 1.

Embodiment 3

[0128] The wave-absorbing composite coating is composed of impedance matching coating and bottom carbon black coating, and the impedance matching coating is composed of 62%-73% resin solution, 16%-30% nano-β silicon carbide, 1%-2% nano-nickel, 1 % to 9% polystyrene, and the bottom carbon black coating is composed of 79% to 81% resin solution and 19% to 21% carbon black. The preparation method and spraying method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com