Novel barium stannate-lead ferroelectric and piezoelectic ceramic, and preparation thereof

A technology of barium stannate and lead titanate, applied in the field of ferroelectric ceramics, can solve the problems of easy depolarization and limited application, and achieve the effects of low cost, controllable components and high chemical purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

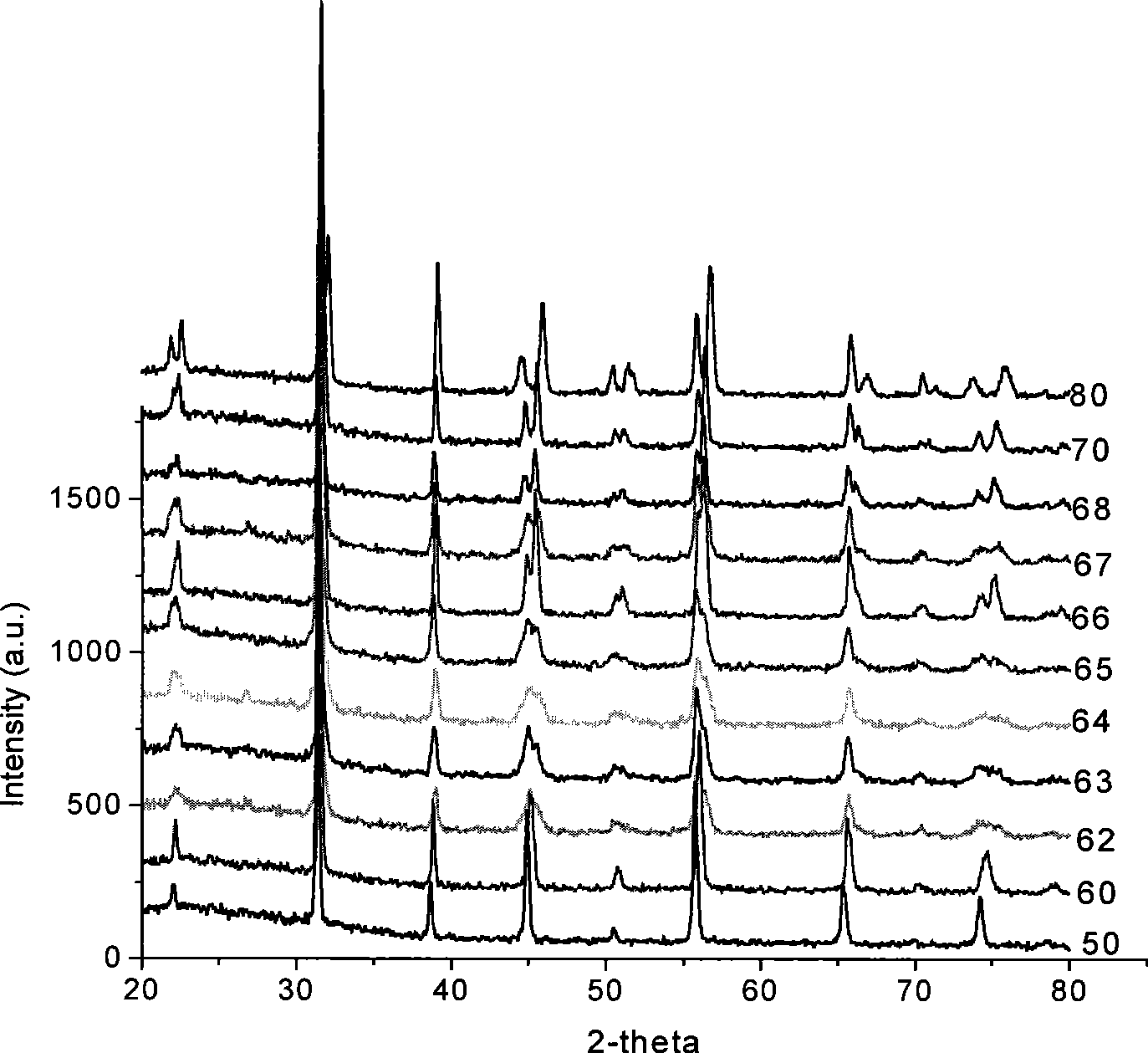

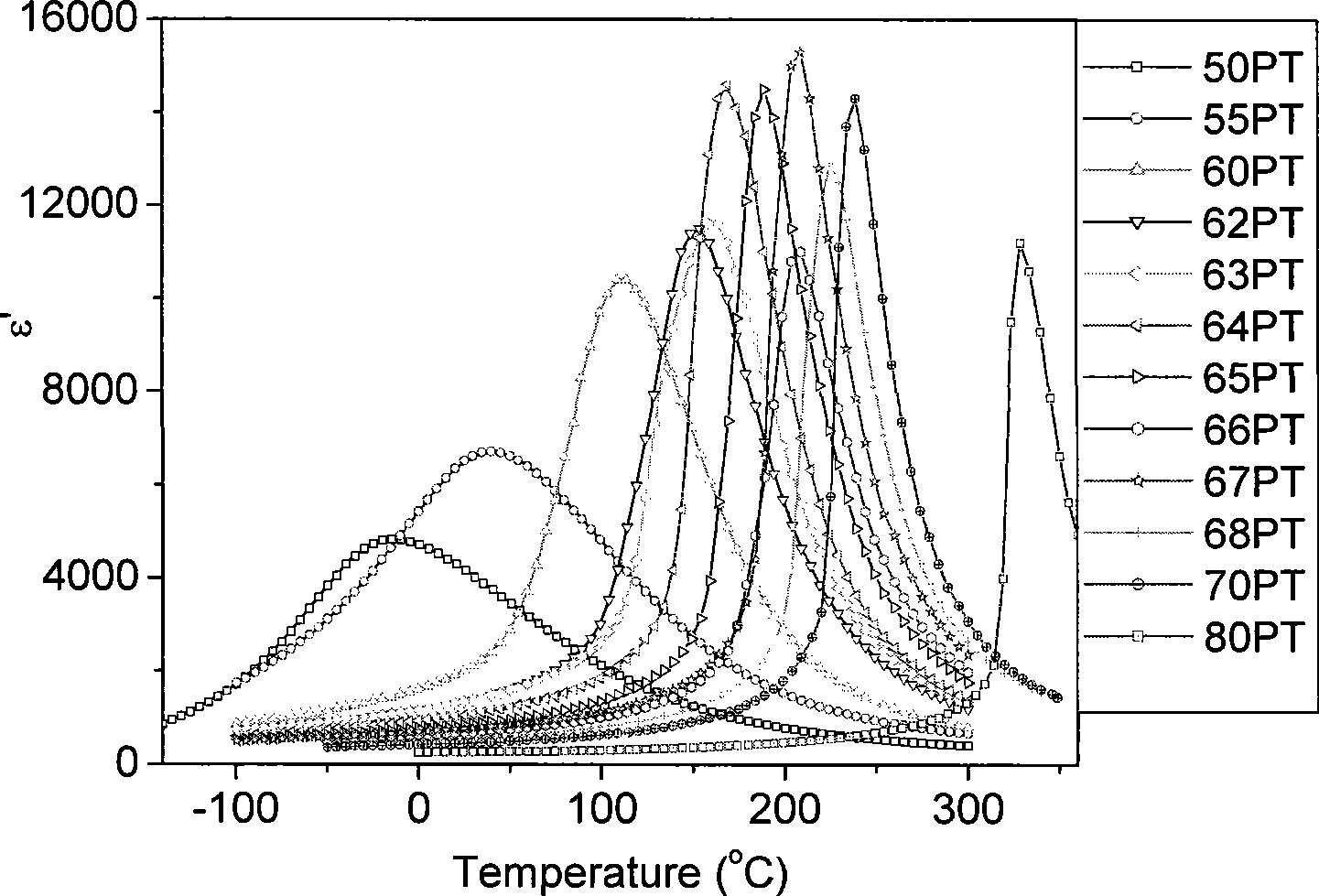

[0016] Example 1: Synthesis of 0.45BaSnO by a two-step synthesis method 3 -0.55PbTO 3

[0017] In the first step, the initial raw material BaCO 3 , SnO 2 , PbO, TiO 2 Press BaSnO 3 And PbTO 3 The content of the chemical formula is weighed, and after mixing, grinding, drying and other processes, they are respectively calcined at 1000℃ (2-4 hours) to pre-synthesize BaSnO 3 And PbTO 3 raw material. The second step is to press the above raw materials into 0.45BaSnO 3 -0.55PbTO 3 The formula requires weighing, mixing, grinding, drying, and molding (add proper amount of binder such as distilled water, 5-10% polyvinyl alcohol solution), molding pressure 5-10MPa, and then sintering (heat preservation for 4 hours), This is the ferroelectric ceramic developed by the present invention. By measuring the dielectric properties of the component ceramics, it is found that it has a strong dielectric relaxation phenomenon, and has a large dielectric constant (7800) at room temperature.

Embodiment 2

[0018] Example 2: Synthesis of 0.40BaSnO by solid phase synthesis 3 -0.60PbTO 3 .

[0019] The initial raw material BaCO 3 , SnO 2 , PbO, TiO 2 Press BaSnO 3 And PbTO 3 The content of the chemical formula is weighed, after mixing, grinding, drying, and molding, the molding pressure is 5MPa, and then the temperature is kept at 800-1000℃ for 3 hours. After solid-phase reaction, 0.40BaSnO with perovskite phase structure is obtained. 3 -0.60PbTO 3 Compound, the product is re-pulverized, ground, dried, molded, and then heated to 1200-1300°C for sintering (holding for 3 hours), which is the ferroelectric ceramic developed by the invention. Through the measurement of the dielectric and piezoelectric properties of the component ceramics, the Curie point of the component ceramics is 120℃, and the piezoelectric constant d 33 It is 320pC / N.

Embodiment 3

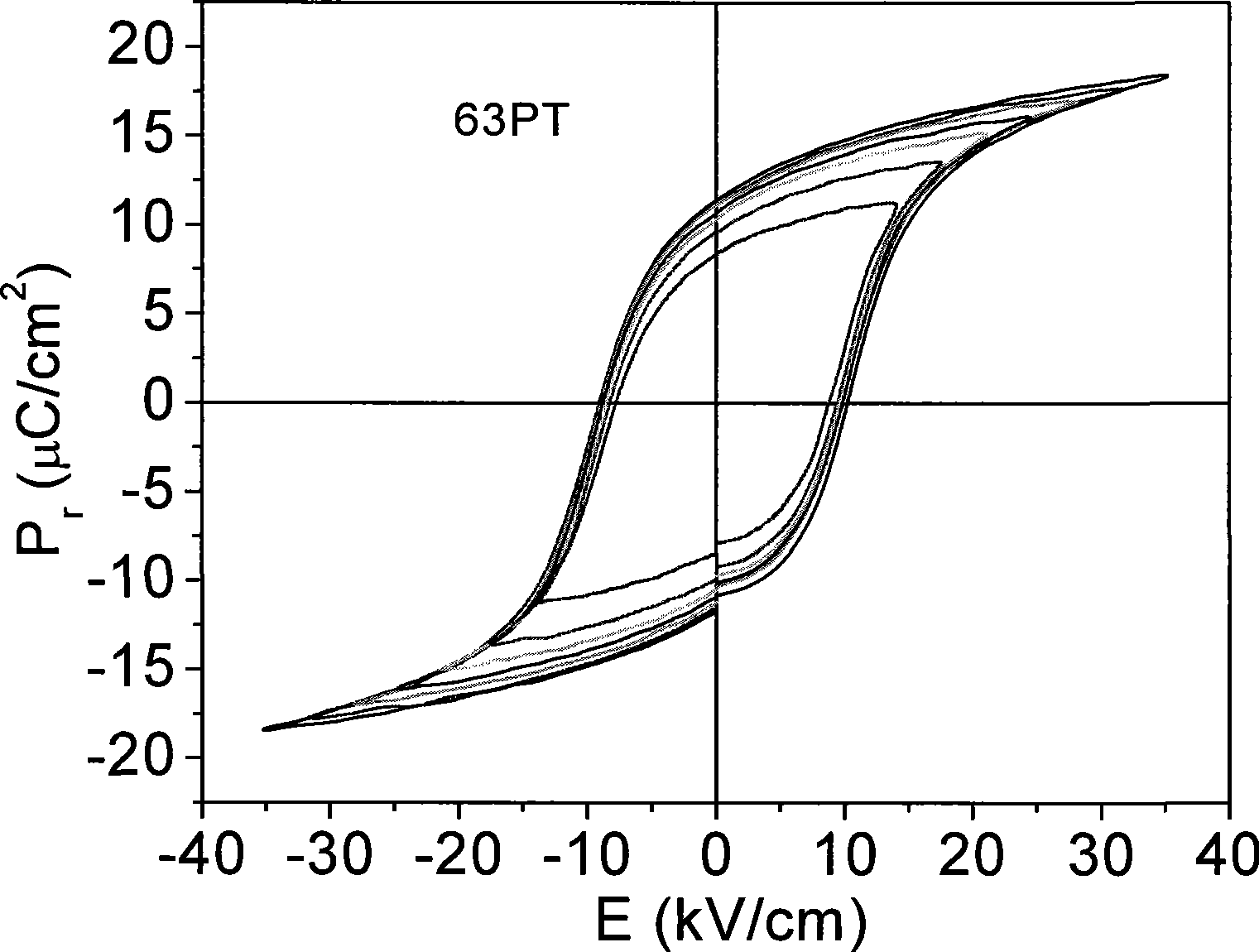

[0020] Example 3: Synthesis of 0.35BaSnO by solid phase synthesis 3 -0.65PbTO 3 .

[0021] The initial raw material BaCO 3 , SnO 2 , PbO, TiO 2 Press BaSnO 3 And PbTO 3 The content of the chemical formula is weighed, after mixing, grinding, drying, and molding, the molding pressure is 3MPa, and then the temperature is kept at 800-1000℃ for 2 hours. After solid-phase reaction, 0.35BaSnO with perovskite phase structure is obtained. 3 -0.65PbTO 3 Compound, the product is pulverized, ground, dried, molded, and then heated to 1200-1300°C for sintering (heat preservation for 4 hours), which is the ferroelectric ceramic developed by the present invention. By measuring the dielectric and piezoelectric properties of the component ceramics, the Curie point of the component ceramics is 180℃, and the piezoelectric constant d 33 It is 220pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com