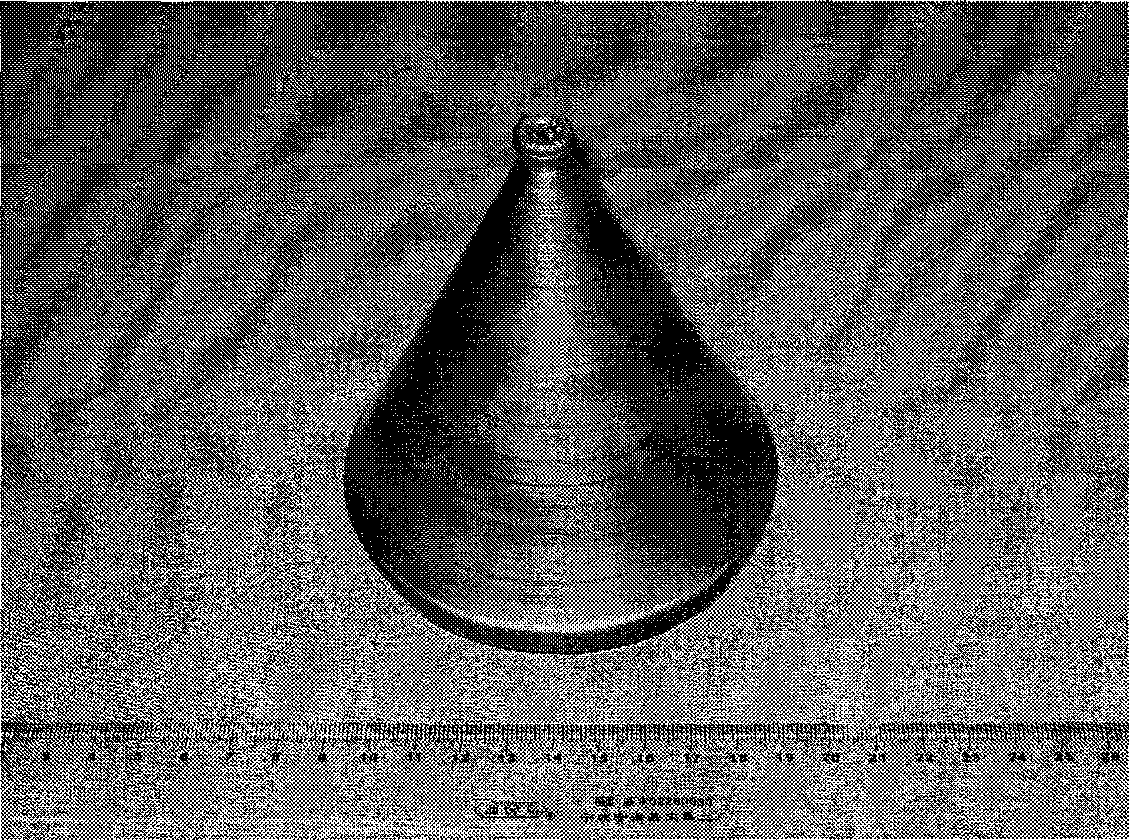

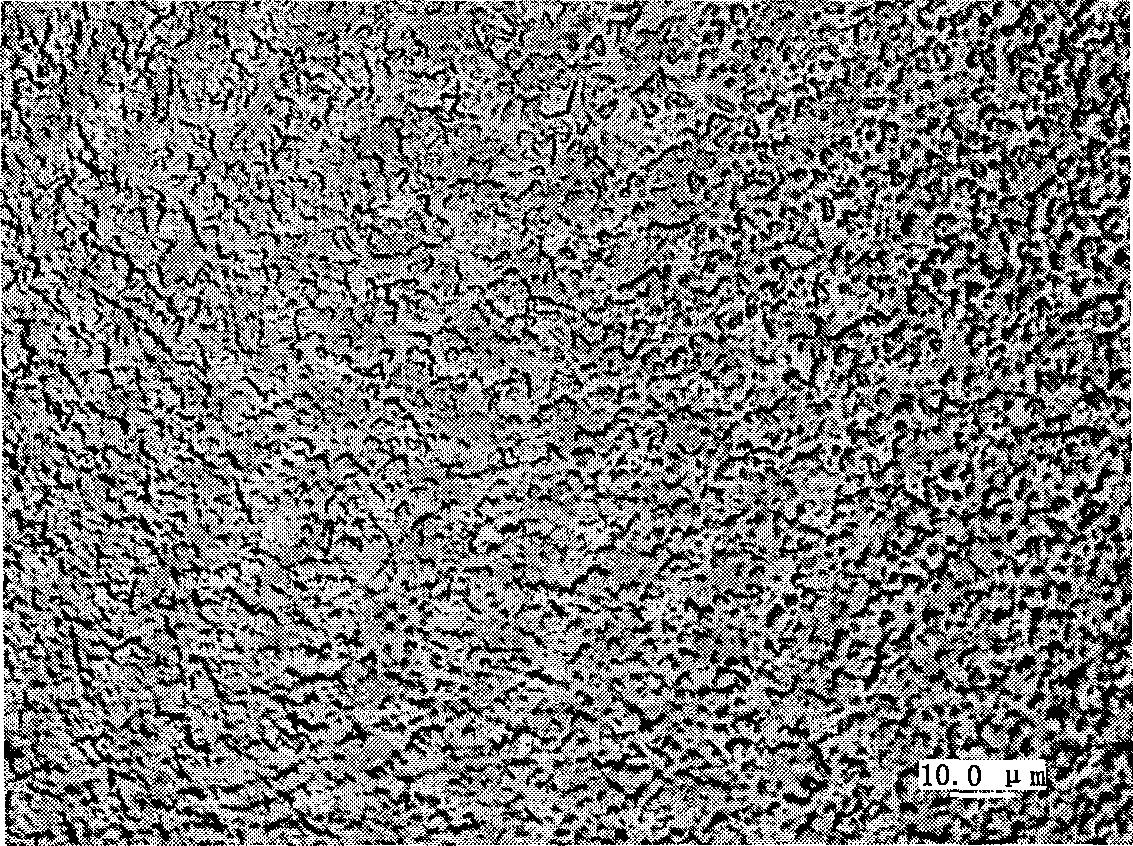

Technology for preparing Ni shaped charge liner using sulfamic acid nickel electroforming solution

A technology of nickel sulfamate and drug-type cover, which is applied in electroforming, ammunition, offensive equipment, etc., can solve the problems of unsatisfactory strength and unstable performance of electroformed nickel deposits, and achieve stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preparation of nickel sulfamate electroforming solution: add 10,000 g of nickel sulfamate, 250 g of nickel chloride, 750 g of boric acid, and 0.75 g of saccharin in an electroforming tank with a volume of 50 L, add 15 L of deionized water, and stir ( 70r / min) to 50°C and hold for 10h. Take a 3000mL beaker and wash it with deionized water, dry it, add 22.5g sodium lauryl sulfate, 2.5g butynediol, add 1500mL deionized water, stir and heat to boiling, wait for sodium lauryl sulfate and butynediol After the diol is dissolved, slowly pour it into the prepared nickel sulfamate solution, and then add deionized water to make the solution 25L. Stir fully and keep warm (50°C) for 12h.

[0015] Pretreatment of cathode mandrel and electrolytic nickel anode: subject the cathode mandrel to 1000 # Polish silicon carbide water sandpaper, wash with tap water, immerse in acetone solution for ultrasonic cleaning for 20 minutes, take out deionized water for cleaning, dry, immerse in a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com