Phosphor, method for producing same, phosphor-containing composition, light-emitting device, image display, and illuminating device

A technology of a light-emitting device and a manufacturing method, applied in the field of phosphors, can solve the problems of low luminance, low conversion efficiency of blue light or near-ultraviolet light, and narrow range of phosphor color reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~8

[0659] As a phosphor raw material, barium carbonate (BaCO 3 ), strontium carbonate (SrCO 3 ), europium oxide (Eu 2 o 3 ), silicon dioxide (SiO 2 ) of the respective powders. These phosphor raw materials are all used with a purity of 99.9% or more and a weight median diameter D 50 It is a powder of 10nm to 5μm. These phosphor raw materials were weighed, and the ratio of each element was set to the molar ratio shown in Examples 1-6 and Comparative Examples 1-8 in Table 3 below. The powders of these phosphor raw materials were mixed until sufficiently homogeneous with an automatic mortar, filled into an alumina crucible, and fired at 1000° C. for 12 hours under atmospheric pressure in air. Next, the contents of the crucible were taken out, and SrCl was added at the molar ratios shown in Examples 1 to 6 and Comparative Examples 1 to 8 in Table 3 below. 2 or NH 4 Cl is used as a flux, and then mixed and pulverized with a dry ball mill. The obtained mixed pulverized product...

Embodiment 7

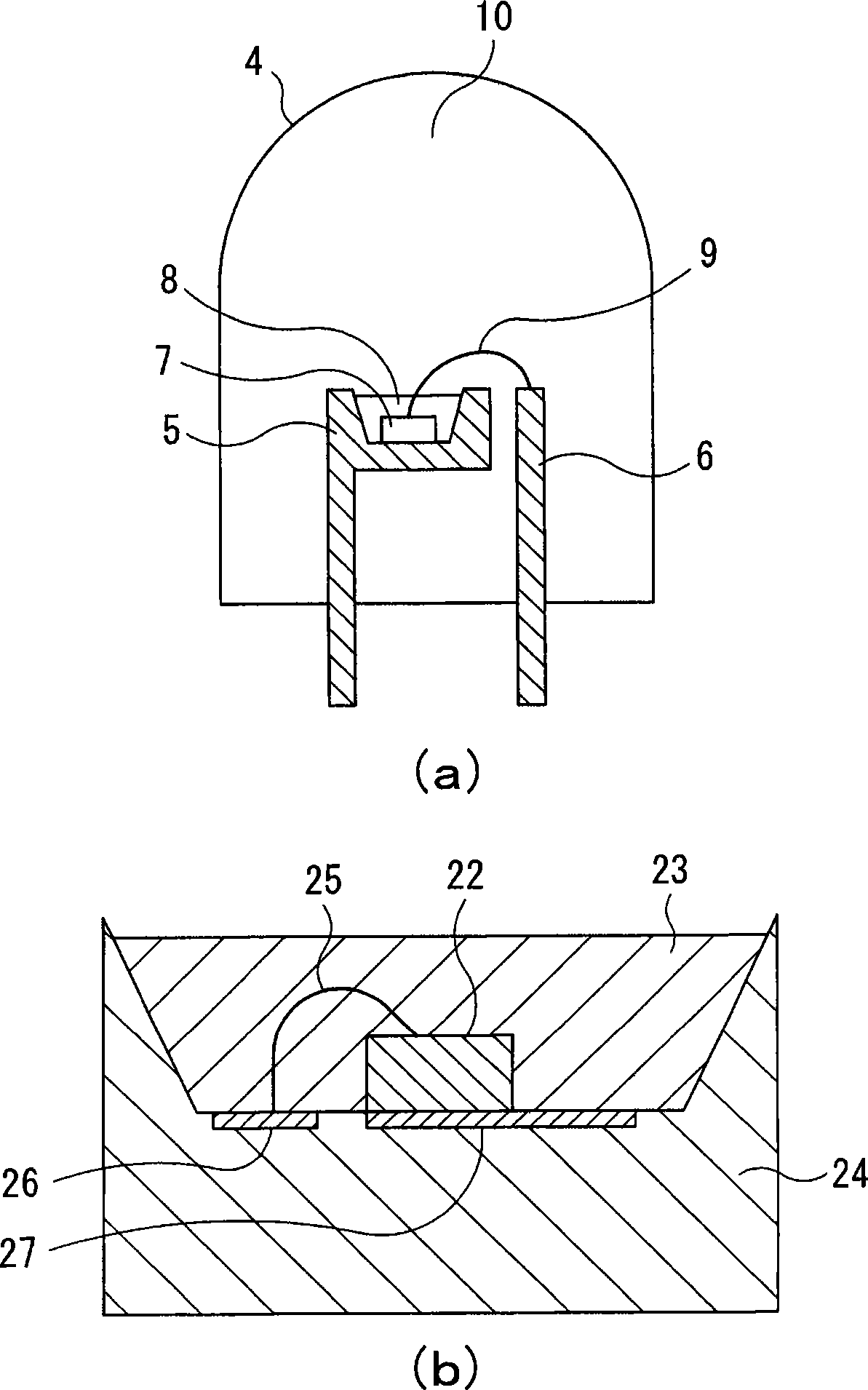

[0705] Make the structure with the above figure 2 The color reproduction range of the same light-emitting device as shown in (b) was evaluated based on the NTSC ratio. The fabrication of the light-emitting device is carried out in the following steps.

[0706] In addition, among the constituent elements of the light-emitting devices produced in the following examples and comparative examples, descriptions and figure 2 (b) For the corresponding constituent elements, the symbols are indicated in parentheses as appropriate.

[0707] As the first illuminant ( 22 ), a blue light-emitting diode (hereinafter simply referred to as "blue LED" for convenience) that emits light with a wavelength of 450 nm to 470 nm, that is, ES-CEBL912 of Epistar Corporation was used. The blue LED (22) is chip bonded to the terminal at the bottom of the recess of the frame (24) using silver paste as an adhesive. At this time, silver paste as a binder is thinly and uniformly applied in consideration of...

Embodiment 8

[0711] As in Example 7, where Ca, which is a phosphor emitting light with a wavelength of about 560nm to 750nm, is used 0.998 Eu 0.08 AlSiN 3 (This phosphor is sometimes referred to as "phosphor (C)") Instead of phosphor (B), the weight ratio of phosphor (A) to phosphor (C) is set to 88:12. The same steps as in Example 7 were used to fabricate a light-emitting device.

[0712] The obtained light-emitting device was made to emit light under the same conditions as in Example 7, and the white chromaticity coordinates thereof were measured, and the result was x / y=0.31 / 0.33. In addition, as an indicator of the color reproduction range, the NTSC ratio was measured according to the method described in the above item [3. Light-emitting device]. The obtained NTSC ratios are shown in Table 8 described later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com