Method for improving dispersion of nano silica granules in polyimide resin

A technology of nano-silica and polyimide resin, which is applied in the field of improving nano-silica particles to achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

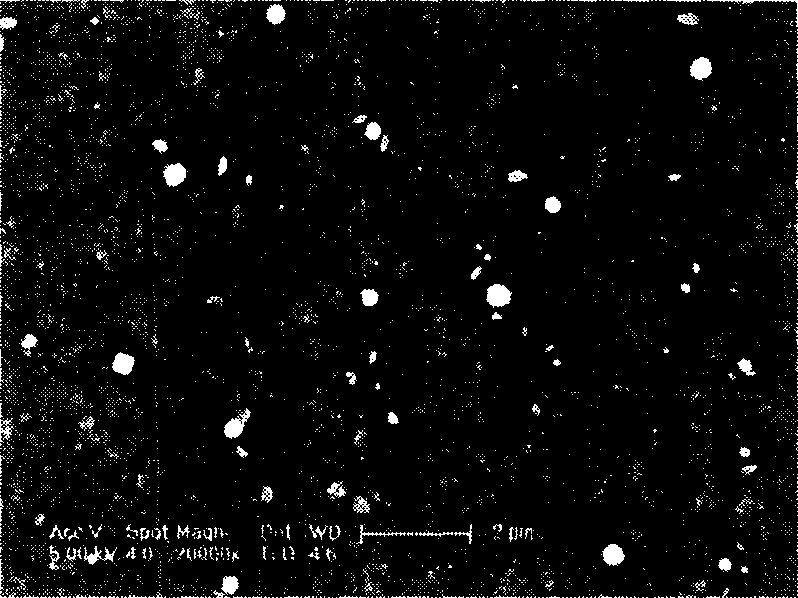

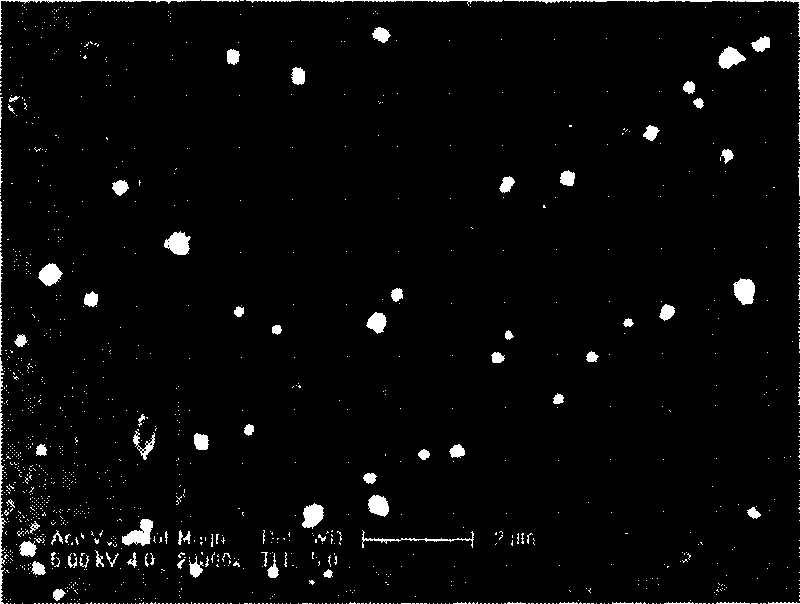

Embodiment 1

[0032] At 80°C, dry the nano-silica particles for 4 hours, and adjust the normal pressure plasma treatment parameters: helium gas flow rate 20L / min, radio frequency power 13.56MHz, power 30W, nozzle-to-substrate distance 2-3mm, make the nozzle and the loaded The distance between the nano-silica substrates (glass vessels) is 2-3 mm, and the nano-silica is treated for 30 seconds. Ultrasonic dispersion of 0.41836 g of treated nano-silica particles and 40 ml of dimethylacetamide solvent, stirring for 1 h, adding pyromellitic dianhydride and 4,4'-diaminodiphenyl ether in a molar ratio of 1:1, Among them, 4.3624g of pyromellitic dianhydride and 4.0048g of 4,4'-diaminodiphenyl ether. Ultrasonic dispersion and continuous reaction at room temperature for 24 hours. In this embodiment, the mass percentage of nano-silica particles in the nanocomposite material is 5%. After desolvation at 80°C, thermal cyclization (100°C, 200°C and 300°C for one hour each), to obtain a nanocomposite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com