High molecule dispersants for polychloroethylene synthesis, high molecule dispersants preparation method and applications

A polymer dispersant, polyvinyl chloride technology, applied in chemical instruments and methods, transportation and packaging, dissolution and other directions, can solve the problems of increasing production process consumption, unfavorable material processing and molding, increasing stirring power, etc. The process is simple and easy to implement, which is conducive to the processing of materials and the effect of solving the problem of compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

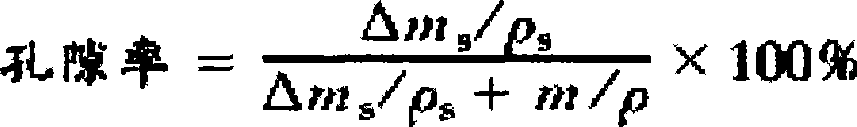

Method used

Image

Examples

example 1

[0016] 1. Prepare the emulsion in a 1 cubic reaction kettle, the steps include: adding

[0017] Deionized water: 280 kg

[0018] DOWFAX 2A1: 6 kg

[0019] Butyl acrylate: 80 kg

[0020] Methyl methacrylate: 180 kg

[0021] Potassium persulfate: 0.1 kg

[0022] Hanging white block: 0.1 kg

[0023] Stir and heat up to the reaction temperature under nitrogen protection, control the temperature at 80°C for two hours, cool down to 55°C and cool to obtain a polymerized emulsion;

[0024] 2. Take 100 kg of polymerized emulsion, put it into an emulsification tank, add 10 kg of carboxymethyl cellulose, 2 kg of hydrated silicon dioxide, and stir for 1 hour to prepare a new polyvinyl chloride synthetic polymer dispersant;

[0025] 3. Take 1% of this dispersant (relative to the mass of vinyl chloride monomer), and 0.5% of polyvinyl alcohol (relative to the mass of vinyl chloride monomer), combine it into a composite dispersion system, add it to deionized water and stir for 30 minutes...

example 2

[0027] 1. Replace the butyl acrylate in Example 1 with n-butyl methacrylate, and keep the others unchanged to obtain the dispersant of the present invention.

[0028] 2. Keeping the other things unchanged, get polyvinyl chloride resin.

example 3

[0030] 1. Replace the methyl methacrylate in Example 1 with styrene and acrylonitrile (styrene and acrylonitrile are used in a mass ratio of 4:1), and polymerize the other materials unchanged to obtain the material of the present invention.

[0031] 2. Keeping the other things unchanged, get polyvinyl chloride resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com