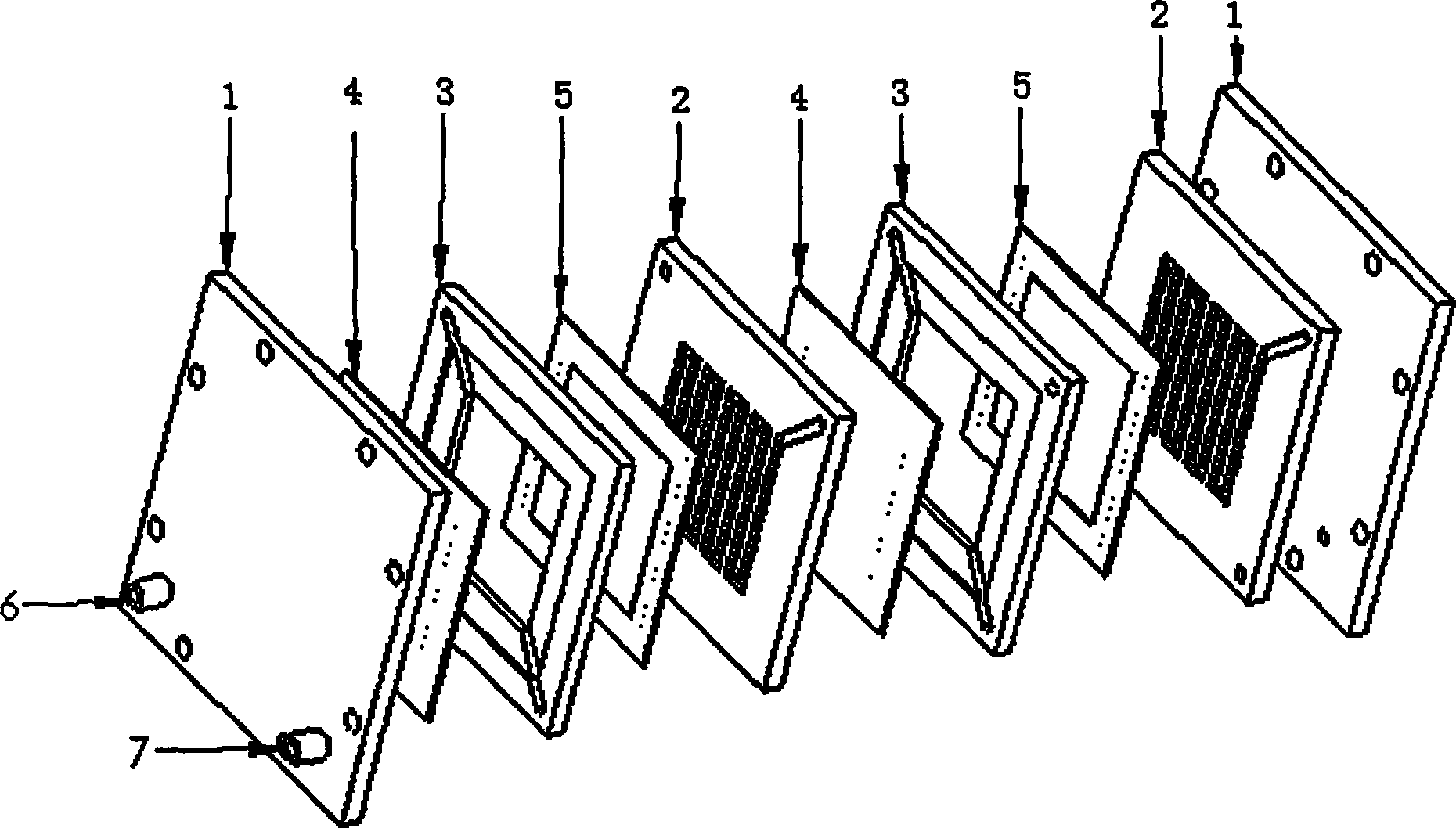

Non-film type direct borohydride fuel cell pack

A technology of fuel cell stack and borohydride, which is applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of high cost, low fuel cell efficiency, complex structure, etc., and achieve low cost, simple structure, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

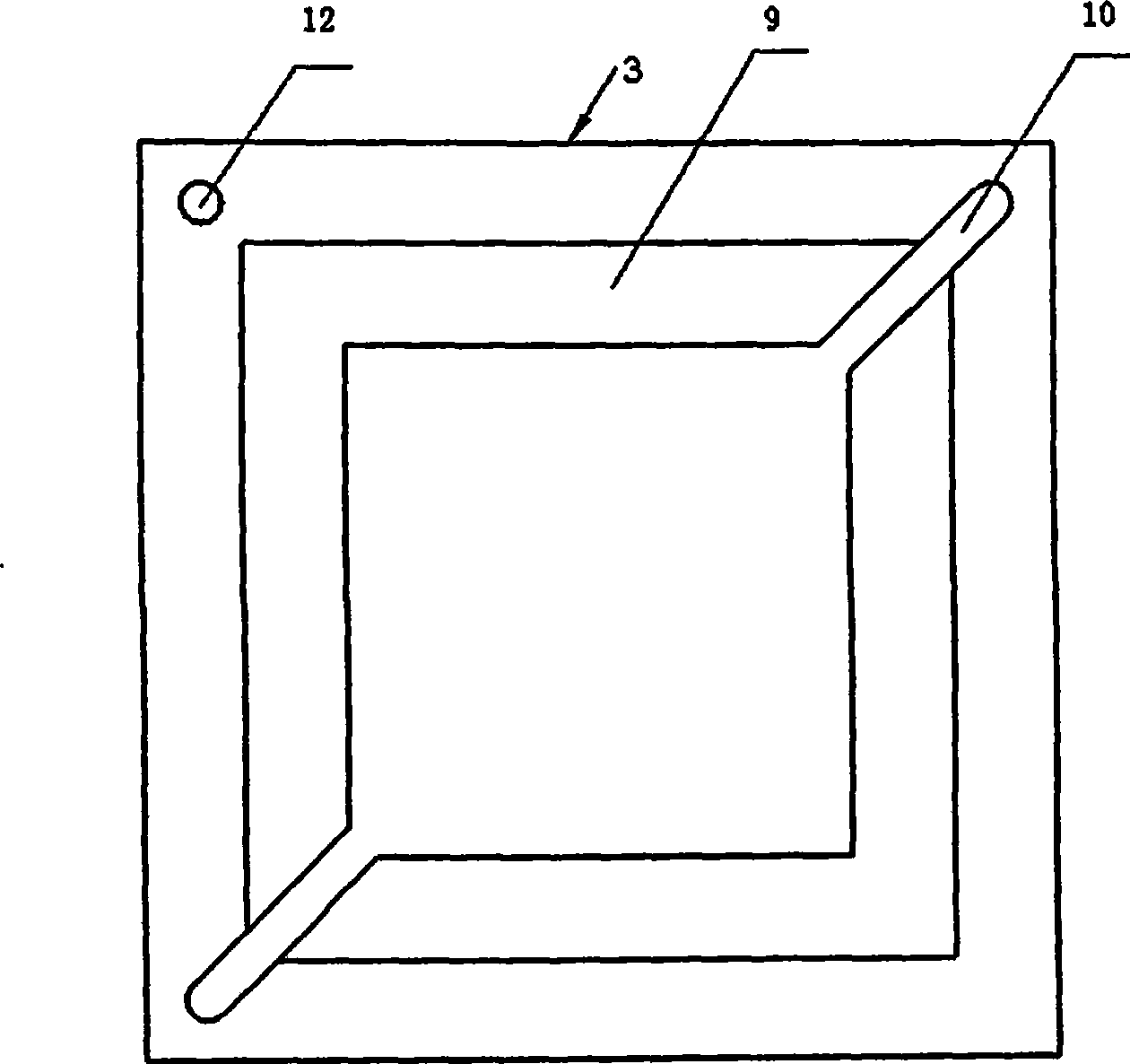

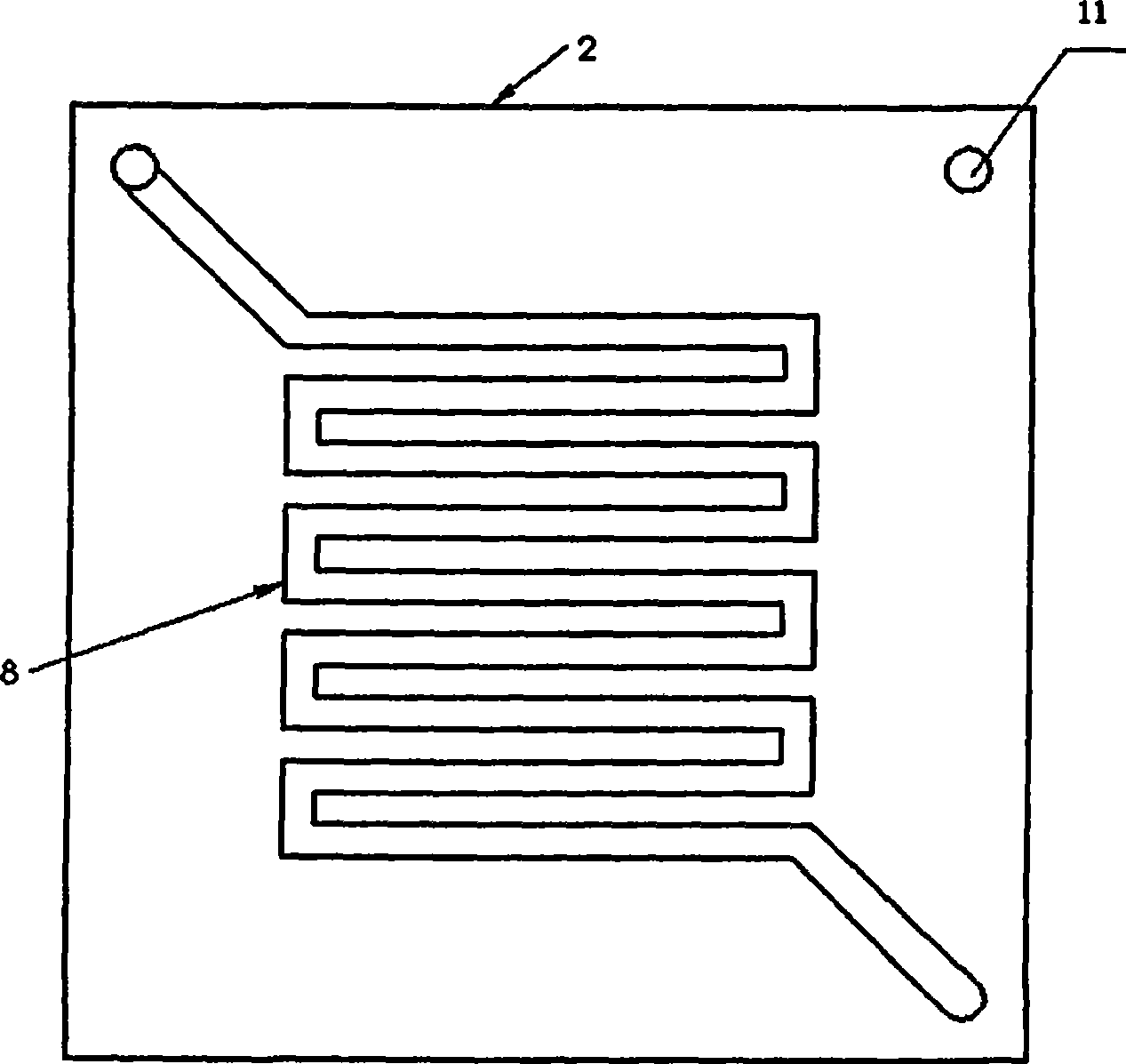

Method used

Image

Examples

preparation example Construction

[0027] 1) Preparation of breathable membrane

[0028] First, mix acetylene black and polytetrafluoroethylene according to the mass ratio of 20-80:20-80, then use absolute ethanol to ultrasonically disperse until viscous, and form a film after repeated rolling, with a thickness of 0.1-0.5mm;

[0029] 2) Preparation of cathode

[0030] First, the catalyst (iron phthalocyanine or cobalt phthalocyanine), carbon carrier (one or more mixtures of activated carbon, carbon nanotubes and acetylene black) and binder (polytetrafluoroethylene, PTFE, polyvinyl alcohol, PVA ) is mixed according to the mass ratio of 10-40:30-50:10-60 and added with absolute ethanol to make a paste mixture, and the paste mixture is applied to one side of the current collector by smearing method, which can reduce material transmission resistance, significantly reducing the internal resistance of the battery. Then, on the other side of the current collector, a gas-permeable film with a thickness of 0.2-0.8 mm ...

Embodiment 1

[0037] Figure 4 Performance curve of a direct borohydride fuel cell with cobalt phthalocyanine as the cathode catalyst. The electrode preparation process is as follows: the oxygen electrode uses cobalt phthalocyanine as the cathode catalyst, and the composition of the catalytic layer is mixed according to the weight ratio of cobalt phthalocyanine, activated carbon, and binder = 20:50:70, and then coated on the foam nickel roller after dispersion pressed into a catalytic layer. Diffusion layer composition: acetylene black: adhesive = 70:30 weight ratio mixed, rolled into a film. The catalytic layer and the diffusion layer were made into an oxygen electrode with a thickness of about 0.6mm under the cold pressure condition of 2Mpa. The loading of cobalt phthalocyanine in the oxygen electrode is 3.5 mg.cm -2 ; The hydrogen electrode uses a hydrogen storage alloy as the anode catalyst. The alloy powder is mixed with additives and binders evenly, and then coated on the nickel f...

Embodiment 2

[0041] Figure 5 The discharge performance curve of a direct borohydride fuel cell stack consisting of four single cells with iron phthalocyanine as the cathode catalyst. The electrode preparation process and working conditions are the same as in Example 1, the fuel flow rate is 6mL / min, and the air compressor is 10L / min. It can be seen from the performance curve that the battery stack of the present invention obtains a maximum power of 2.2W under the above test conditions, and the voltage at this time is 1.4V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com