Method for preparing alumina powder for polishing solution

A technology of alumina powder and polishing liquid, which is applied in chemical instruments and methods, alumina/aluminum hydroxide, and other chemical processes, can solve the problem of poor polishing performance and poor dispersion stability of alumina polishing liquid , increase production costs and other issues, to achieve the effect of low cost, good fluidity and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A kind of preparation method of aluminum oxide powder for polishing fluid, the step of its preparation process comprises:

[0014] (1) Using aluminum ammonium sulfate as a raw material, heat and stir with deionized water to dissolve, and configure a concentration of 0.2-0.4M aluminum ammonium sulfate solution;

[0015] (2) Ammonium aluminum sulfate solution is added in the constant temperature reactor, and urea and catalyst are added thereinto, stirred, and the solution reacts to generate precipitation;

[0016] (3) After the reaction is complete, continue to stir for half an hour, age, wash twice, filter, and dry in a drying oven at 80°C for 12 hours to obtain a dry precursor;

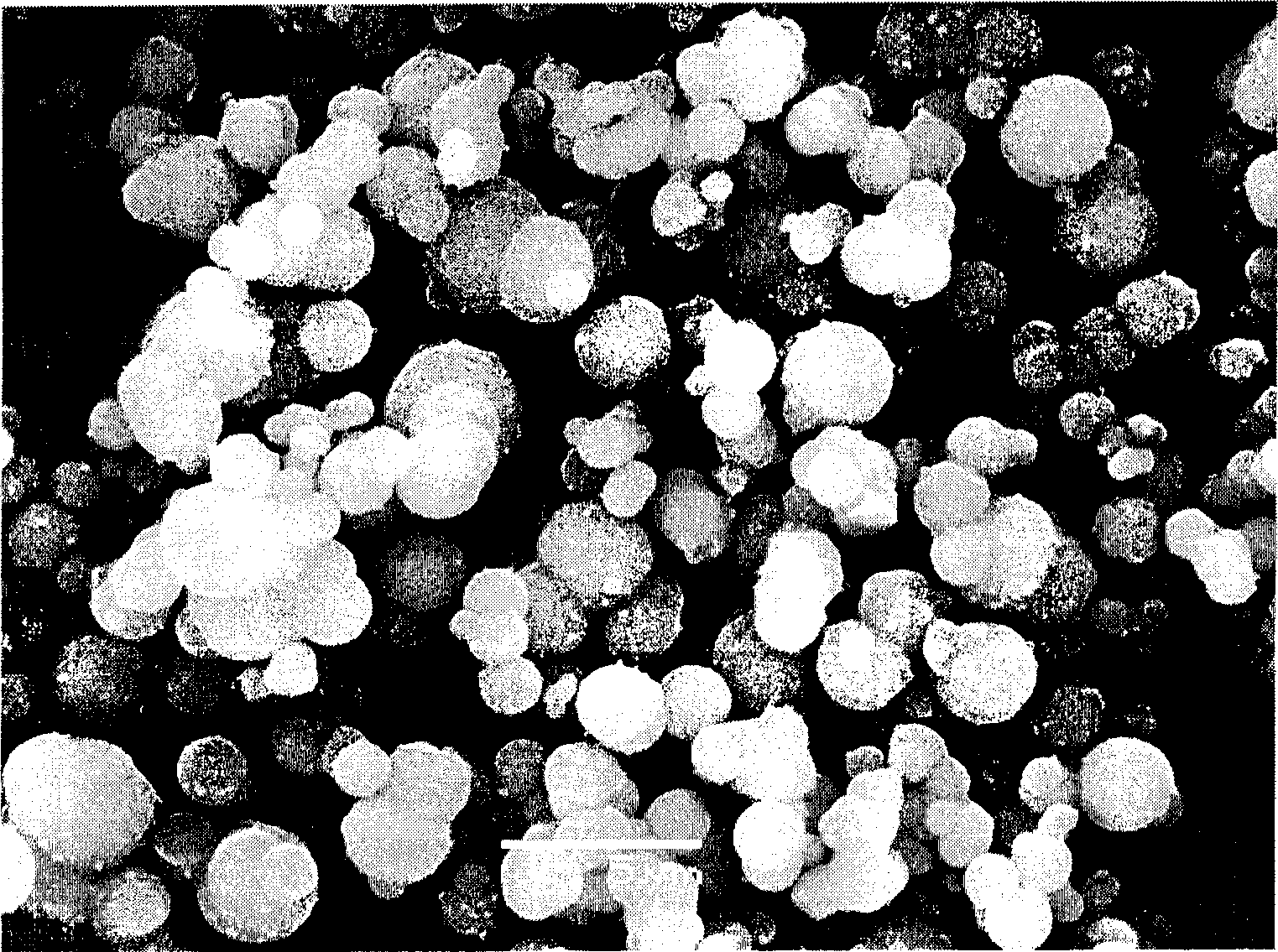

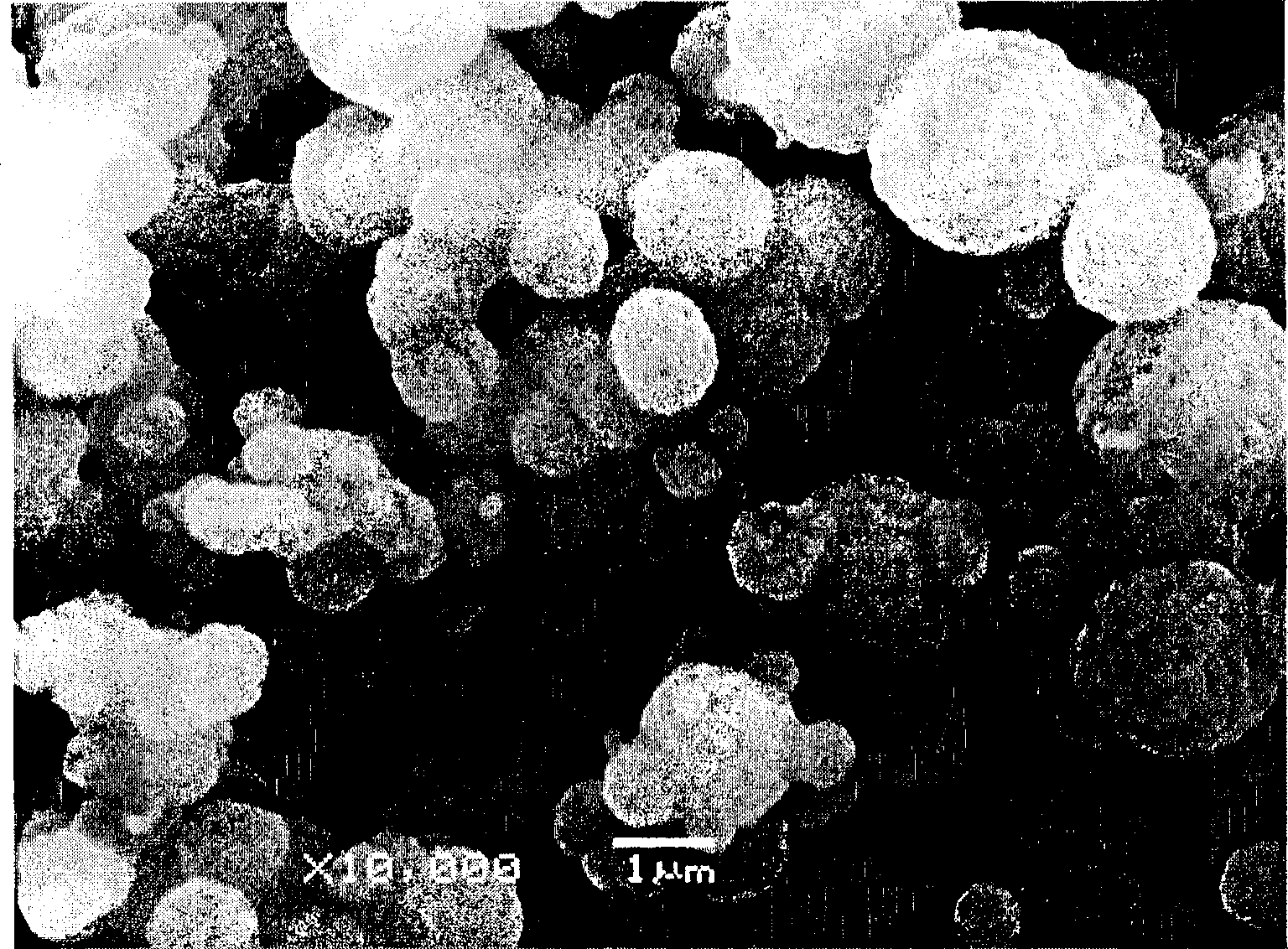

[0017] (4) Calcining the spherical alumina precursor in a muffle furnace at 1200-1600° C. for 2-6 hours, and sieving the obtained product to obtain spherical alumina with a uniform particle size and nanostructure.

[0018] In the preparation method of alumina powder for polishing liquid of the...

Embodiment 1

[0023] Put 80 grams of ammonium aluminum sulfate into a clean 1000 ml beaker, add 800 ml of pure water, heat to dissolve, add 100 grams of urea and 0.75 grams of urease, put it into a constant temperature reactor, set the water bath temperature to 60-80 ° C, The beaker was heated in a water bath while the stirring speed was adjusted to 200rpm to stir the solution. After 3 hours, a precipitate appeared, and after aging for 0.5 hour, it was filtered and washed. Calcined at 1200-1600°C for 2-6 hours in a muffle furnace to obtain spherical α-alumina.

Embodiment 2

[0025] Put 120 grams of ammonium aluminum sulfate into a cleaned 1000 ml beaker, add an appropriate amount of pure water to 800 ml, heat to dissolve, add 100 grams of urea and 0.75 grams of urease, put it into a constant temperature reactor, set the water bath temperature to 60- 80°C, heat the beaker in a water bath, and at the same time adjust the stirring speed to 200rpm to stir the solution. After about 3.5 hours, a precipitate appeared, and after aging for 0.5 hour, it was filtered and washed. Calcined at 1200-1600°C for 2-6 hours in a muffle furnace to obtain spherical α-alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com