Method for preparing developing polyurethane

A polyurethane and developable technology, applied in catheters, medical science, prostheses, etc., can solve the problems of product change, loss of developable atoms, etc., and achieve the effect of easy processing, good physical properties, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Its preparation method comprises steps:

[0024] (1) Mix polymer diol and diisocyanate, the molar ratio of mixing is: polymer diol:diisocyanate=0.25~0.80:1, stir and mix at 60~85°C for 2~5 hours under nitrogen protection , to obtain the prepolymer;

[0025] (2) Raise the temperature of the above-mentioned prepolymer to 80-100°C, add a chain extender in a molar ratio: chain extender: diisocyanate = 0.20-0.75:1, and stir for about 5-120 minutes;

[0026] (3) Curing the above polymer at a temperature of 80±5° C. for 3 to 12 hours.

[0027] In the method of the present invention, the solution polymerization method can also be used in the reaction process, adding a solvent to the system to stir the reaction, and the chain extension reaction takes about 1 to 4 hours to discharge the material, purify and mature to obtain the developable polyurethane. The effect of adding a solvent is to reduce the viscosity of the system and make the reactants mix more evenly, so that the re...

Embodiment 1

[0030] Mix the pre-vacuum dehydrated polytetrahydrofuran ether diol with a molecular weight of 1000 and 4,4'-diphenylmethane diisocyanate in a molar ratio of 0.74:1, stir and mix at 80°C for 2.5 hours under the protection of nitrogen to obtain Prepolymer; raise the temperature to 85°C, add pre-melted chain extender N, N-dihydroxyethyl-p-iodoaniline, and its molar ratio to 4,4'-diphenylmethane diisocyanate is 0.22:1 , stirring and reacting for about 20 minutes to discharge the material, and aging the obtained polymer at a temperature of 75° C. for 5 hours.

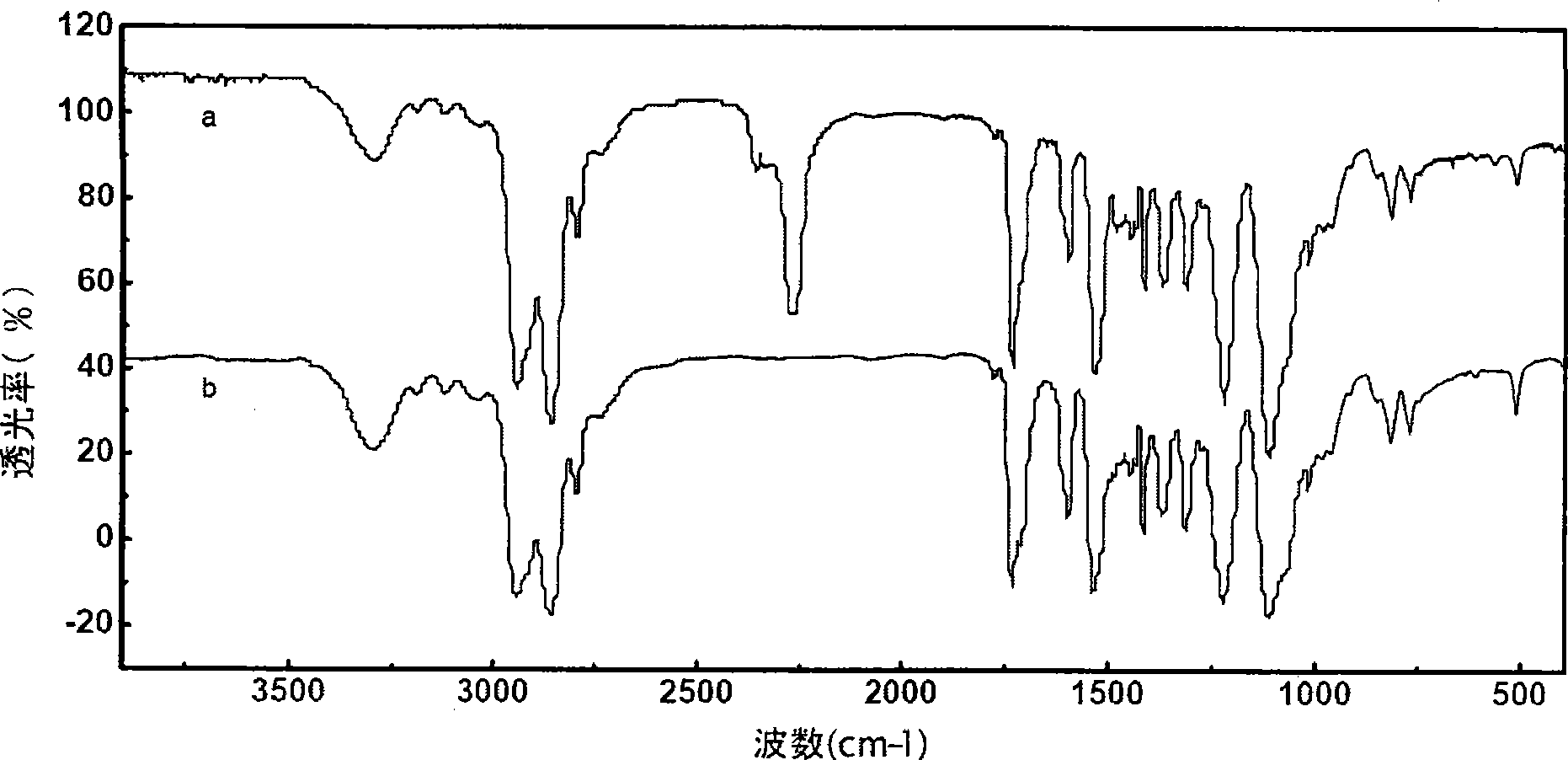

[0031] figure 1 It is the infrared spectrogram of the developable polyurethane (polyether polyurethane) prepared in Example 1. Wherein, a represents the infrared spectrum of the prepolymer synthesized in Example 1, and b represents the infrared spectrum of the developable polyether polyurethane synthesized in Example 1. We can see 3305cm -1 It is the stretching vibration peak of hydrogen bond association NH, but it is not ...

Embodiment 2

[0033] Mix the pre-vacuum dehydrated polytetrahydrofuran ether diol with a molecular weight of 2000 and isophorone diisocyanate in a molar ratio of 0.46:1, stir and mix at 78°C for 5 hours under the protection of nitrogen to obtain a prepolymer; Temperature to 85°C, add pre-melted chain extender N, N-dihydroxyethyl p-iodoaniline, the molar ratio of it to isophorone diisocyanate is 0.49:1, stir for about 3 hours, add 0.08% of the total mass % catalyst stannous octoate, and then stirred for 10 minutes, discharged, and the obtained polymer was matured at a temperature of 75° C. for 4 hours.

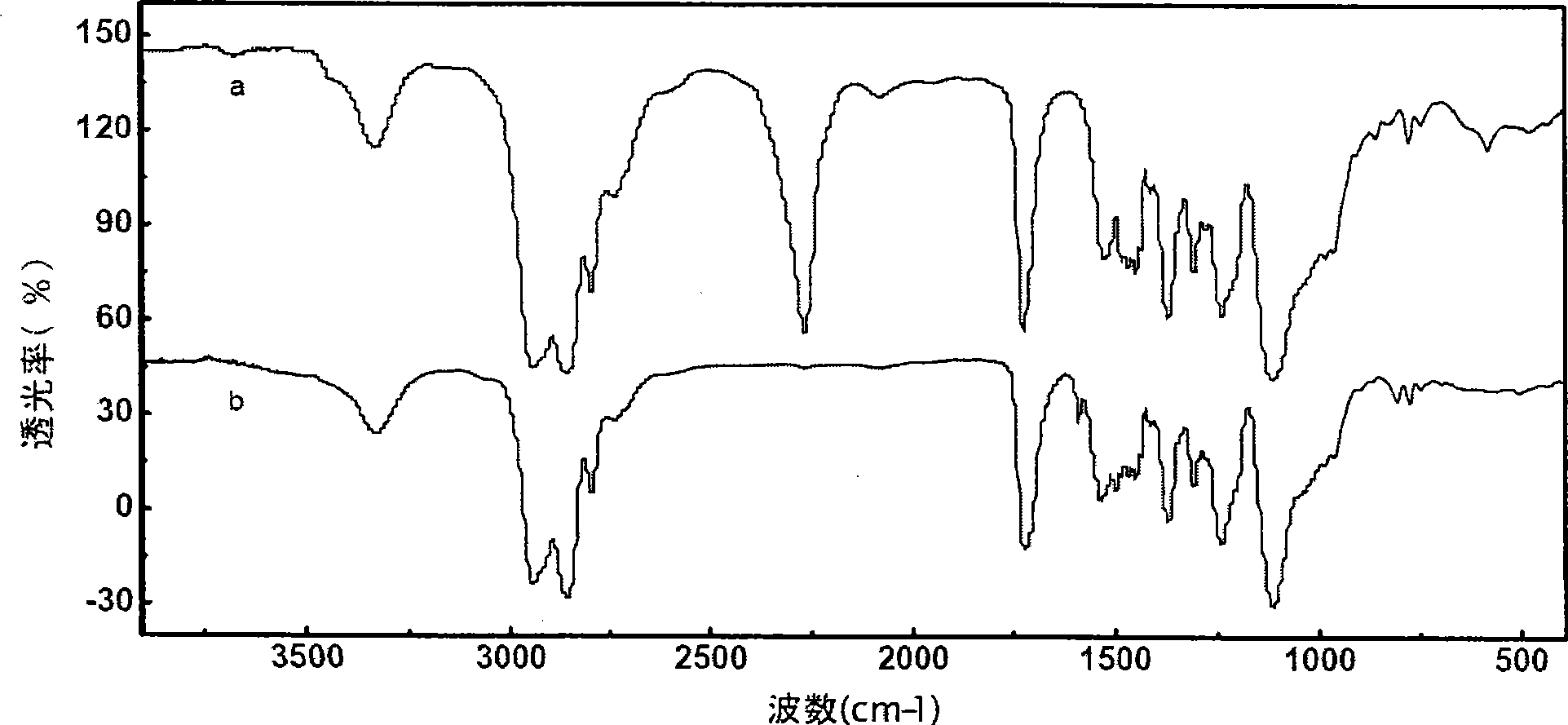

[0034] figure 2 It is the infrared spectrogram of the developable polyurethane (polycarbonate polyurethane) prepared in embodiment 2, wherein, a represents the prepolymer infrared spectrogram synthesized in embodiment 2, and b represents the developable polycarbonate type synthesized in embodiment 2 Infrared spectrum of polyurethane. We can see 3334cm -1 It is the stretching vibration pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com