Method and device for continuously preparing acidic phosphor/phosphine extractant rare earth soap by lime milk

A technology for extracting agent and milk of lime, applied in the field of continuous saponification of milk of lime to prepare extractant rare earth soap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

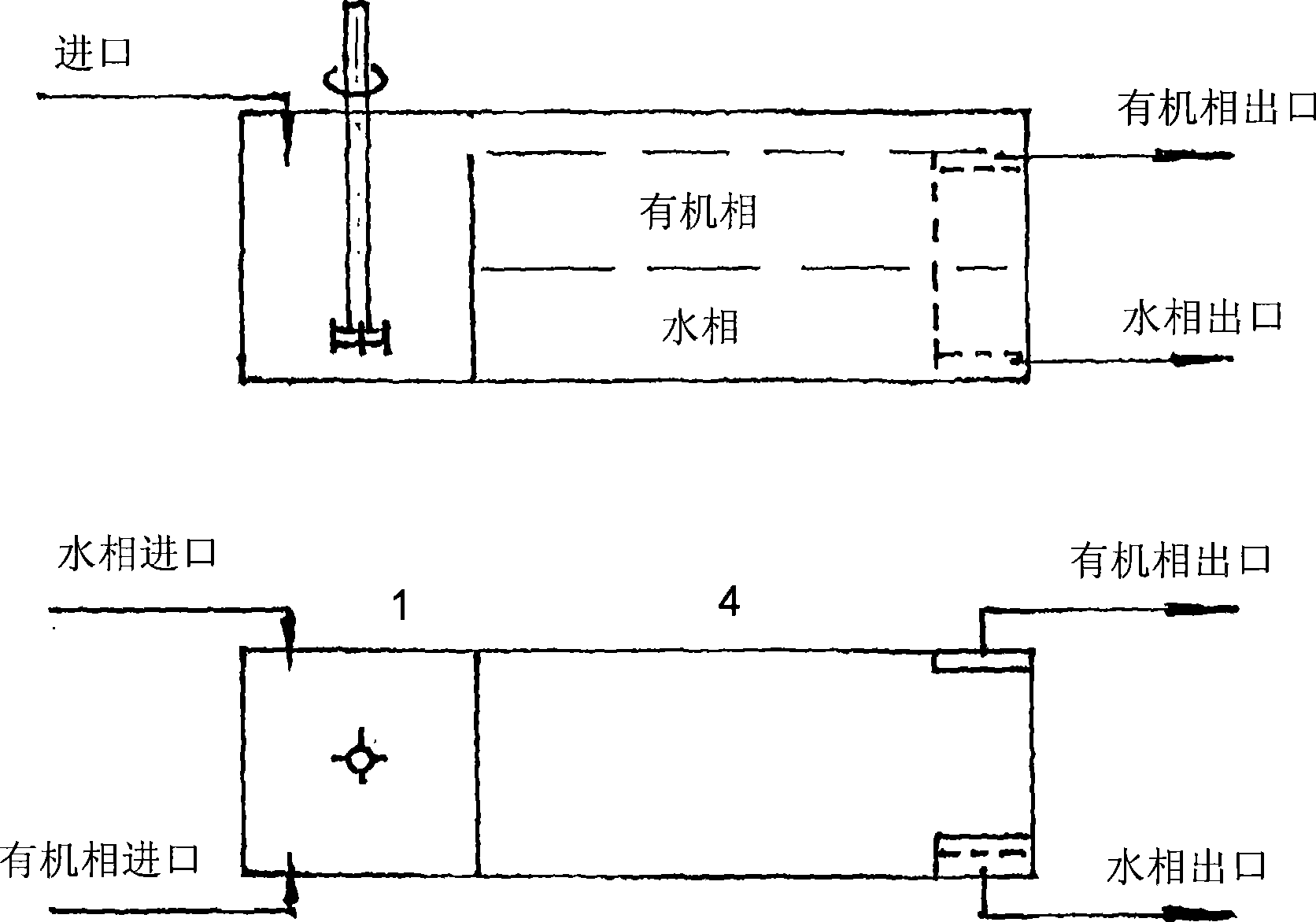

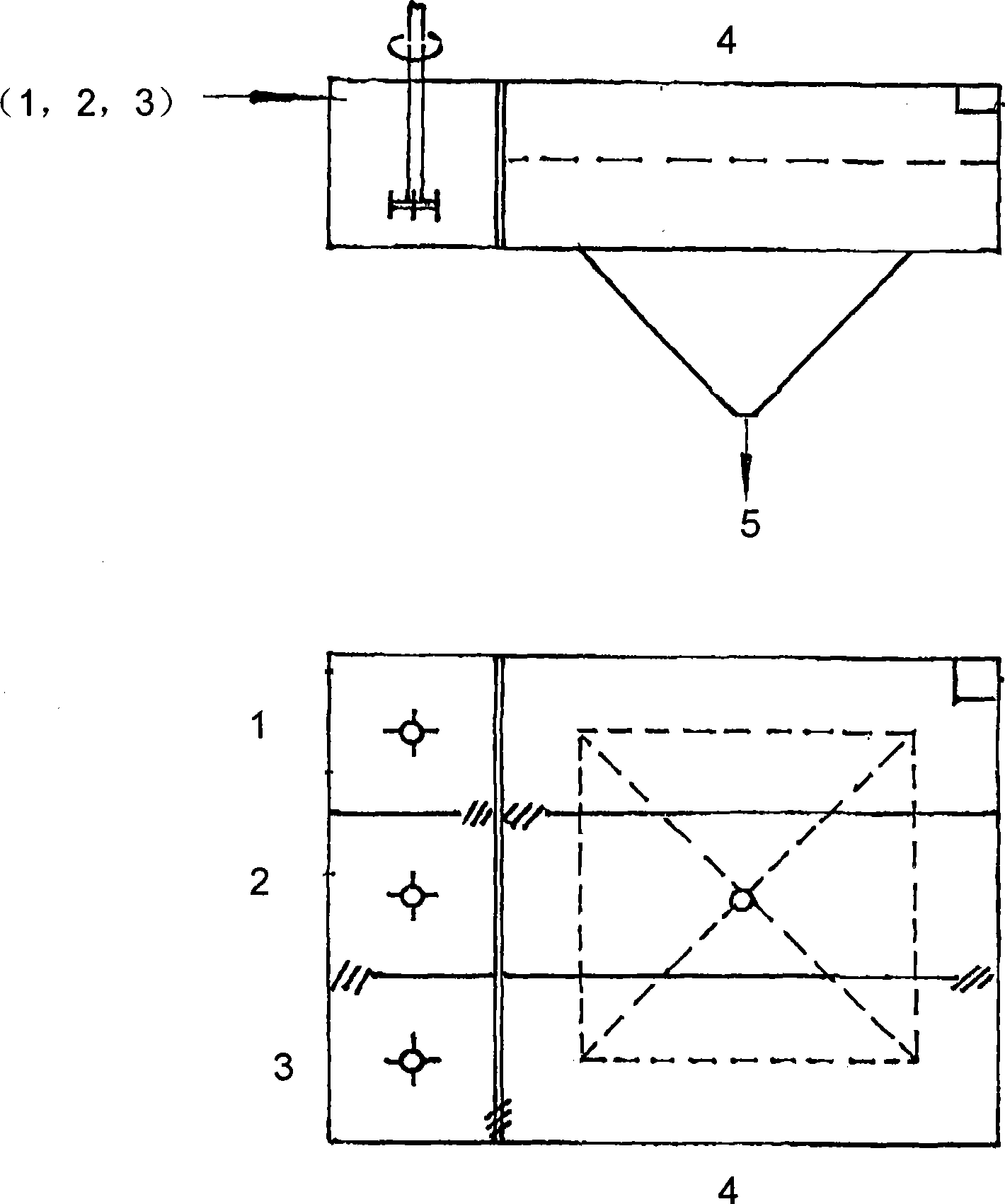

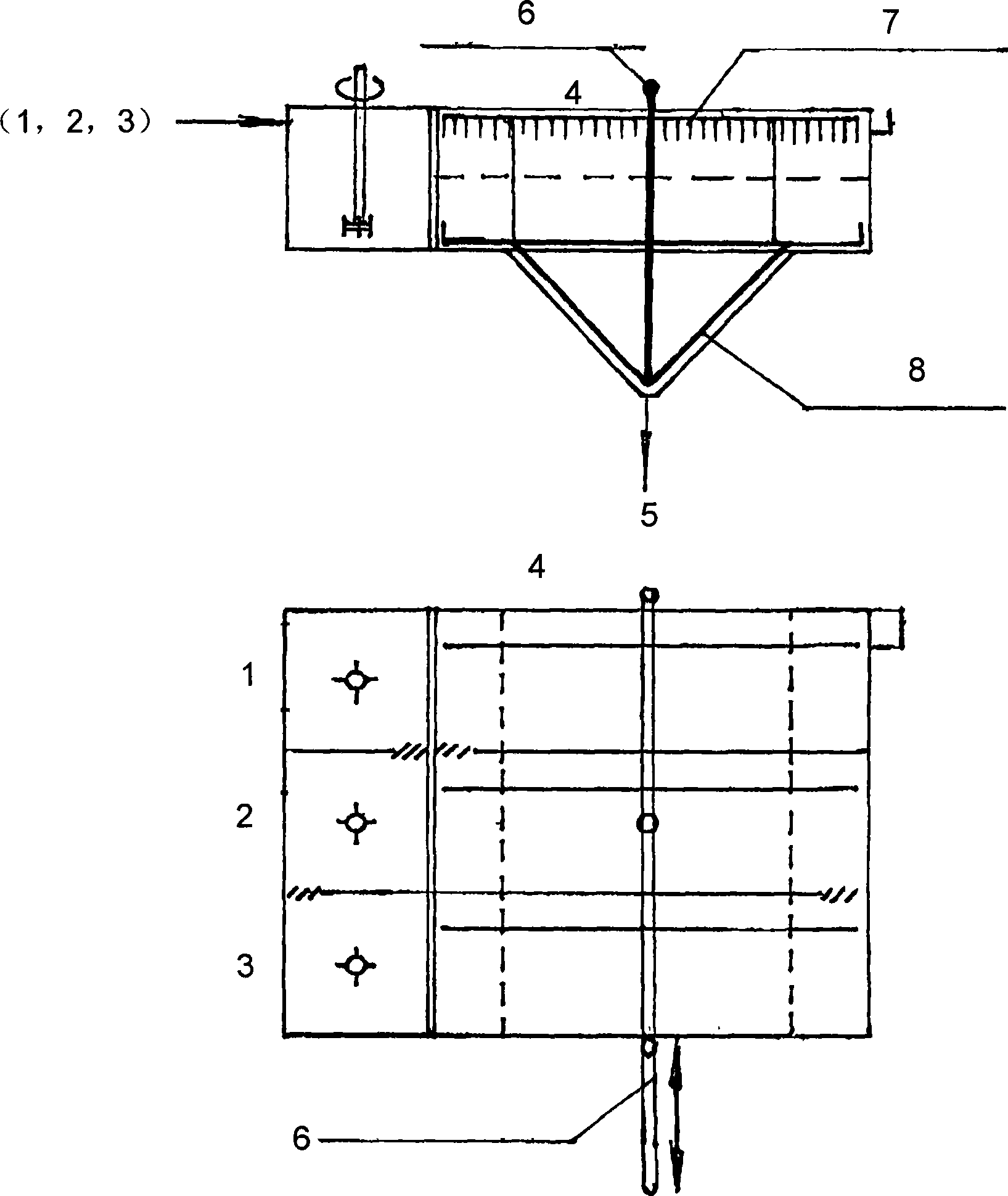

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the continuous preparation of extractant lanthanum soap organic phase in lanthanum cerium separation flow process

[0054] Process conditions:

[0055] Milk of lime: OH - The concentration is 5.0N, the flow rate is 3.2 liters / minute

[0056] P204 kerosene solution of organic phase 1.25mol / L, flow rate 35 liters / min

[0057] Lanthanum chloride solution LaCl 3 The concentration is 1.50mol / L, the flow rate is 3.5L / min

[0058] The above materials are introduced into the mixing and settling tank at the same time, mixed for 4 * 3 minutes, and clarified for 40 minutes. After the balance, the measured lanthanum soap concentration in the organic phase is 0.145-0.150mol / L, and the water phase remains (LaCl 3 )<0.01mol / L.

Embodiment 2

[0059] Embodiment 2: the continuous preparation of extractant LaCe soap organic phase in cerium-praseodymium grouping flow process

[0060] Process conditions:

[0061] Milk of lime: OH - The concentration is 4.5N, the flow rate is 3.6 l / min

[0062] P507 kerosene solution of organic phase 1.10mol / L, flow rate 40 liters / min

[0063] Lanthanum cerium chloride solution ReCl 3 The concentration is 1.55mol / L, the flow rate is 3.5L / min

[0064] Import the above materials into the mixing and settling tank at the same time, mix for 3.5×3 minutes, and clarify for 50 minutes. After equilibrium, the measured concentration of lanthanum and cerium soap in the organic phase is 0.130-0.140mol / L, and the residual rare earth (ReCl 3 )<0.01mol / L.

Embodiment 3

[0065] Embodiment 3: Continuous preparation of extractant La—Gd mixed rare earth soap organic phase in dysprosium holmium grouping flow process

[0066] Process conditions:

[0067] Milk of lime: OH - The concentration is 4.5N, the flow rate is 5.0L / min

[0068] P507 kerosene solution of organic phase 1.30mol / L, flow rate 50 liters / min

[0069] La-Gd solution ReCl 3 The concentration is 1.45mol / L, the flow rate is 5.2L / min

[0070] Import the above materials into the mixing and settling tank at the same time, mix for 3.5×3 minutes, and clarify for 45 minutes. 3 )<0.01mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com