Carotenoid preparation and use thereof and feedstuff containing the preparation and preparation method thereof

A carotene and preparation technology, applied in the application, food preparation, animal feed and other directions, can solve problems such as difficulty, uneven distribution of active ingredients, large particle size, etc., to reduce surface oxidation loss, be beneficial to absorption and utilization, and coloring effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

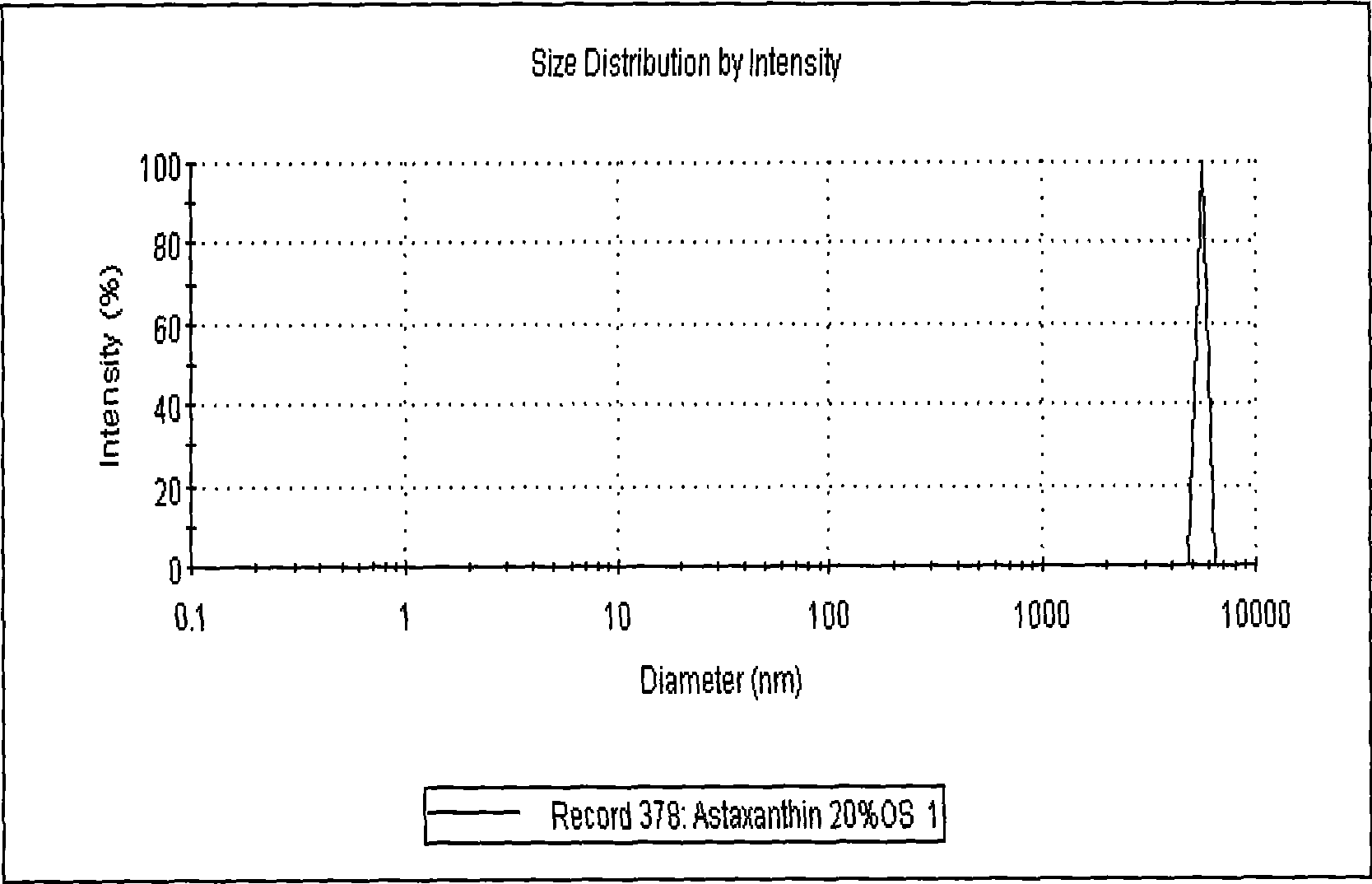

[0039] Preparation of Astaxanthin 20% Oil Suspension

[0040] Weigh 2.2kg of pure astaxanthin (content: 97.2%), 0.3kg of natural vitamin E and 5.0kg of sunflower oil, mix evenly, put it in a ball mill and grind it for 1.5hr, take it out to get a viscous fluid, and then add 2.5kg Sunflower oil, stirred and mixed evenly to obtain a suspension of astaxanthin oil with better fluidity.

[0041] The content of astaxanthin in the oil suspension is 21.2% as measured by ultraviolet spectrophotometry, and the average particle diameter of the particles in the oil suspension is 4.68 μm as measured by a laser particle size distribution analyzer.

[0042] Dissolution of astaxanthin before spraying

[0043] Take 8.0kg of the above-mentioned astaxanthin oil suspension and mix it with a part of 4800kg of oils to be added (a mixture of fish oil and soybean salad oil, their ratio is 2:1), heat up to 60°C and keep it warm for 1.5hr while stirring. Suspended astaxanthin particles are fully disso...

Embodiment 3-6

[0055] The preparation process of oil suspension in embodiment 3-6 is listed in table 1:

[0056] Preparation of oil suspension in table 1. embodiment 3-6

[0057] Example 3 Example 4 Example 5 Example 6 Types of Carotenoids Lutein Canthaxanthin β-carotene Zeaxanthin Types of Vegetable Oil Sunflower seed oil canola oil Corn oil peanut oil Types of antioxidants BHT BHA synthetic vitamin E synthetic vitamin E Carotenoid content in oil suspension 10wt% 20wt% 30wt% 20wt% Antioxidant content in oil suspension 1% 2.5% 10% 5% Particle size distribution of carotenoids in oil suspension 4μm 6μm 3μm 10μm Raise the melting temperature before spraying 30℃ 40℃ 70℃ 70℃ Warming and dissolving time before spraying 5hr 2hr 0.5hr 1.5hr Carotenoid content in final granules 100mg / kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com