Palladium plating liquid for preparing Co/Pd nano-multilayer film by double-flute method electrocrystallization

A nano-multi-layer and electro-crystallization technology, which is applied in the application of magnetic film to substrate, circuits, electrical components, etc., can solve the problems that Co/Pd nano-multi-layer film is easy to break and fall off, and the magnetic properties are greatly affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Plating solution composition:

[0020] Dichlorodiamine palladium 3g / L (calculated as Pd)

[0021] Cerium sulfate 0.02g / L (calculated as Ce)

[0022] Ethylenediamine 65mL / L

[0023] Pyridine-3-sulfonic acid 0.05g / L

[0025] The plating solution was adjusted to pH=8.5 with ammonia water and hydrochloric acid, and the working electrode was single crystal Si(111) (with HF and HNO at a volume ratio of 3:1 3 Mixed acid etching→washing→air drying), the temperature of the plating solution is 25°C, the time for multilayer palladium plating is 30s, and the time for cobalt plating is 2s. Ammonia exposure testing (24 hours at room temperature) was performed and no breakage and cracking of the multilayer film was observed. figure 2 It is the surface topography diagram of the palladium plating, and the palladium plating layer is dense and uniform.

Embodiment 2

[0027] Plating solution composition:

[0028] Dichlorodiamine palladium 3g / L (calculated as Pd)

[0029] Cerium nitrate 0.02g / L (calculated as Ce)

[0030] Ethylenediamine 70mL / L

[0031] Ammonium pyridine-3-sulfonate 0.05g / L

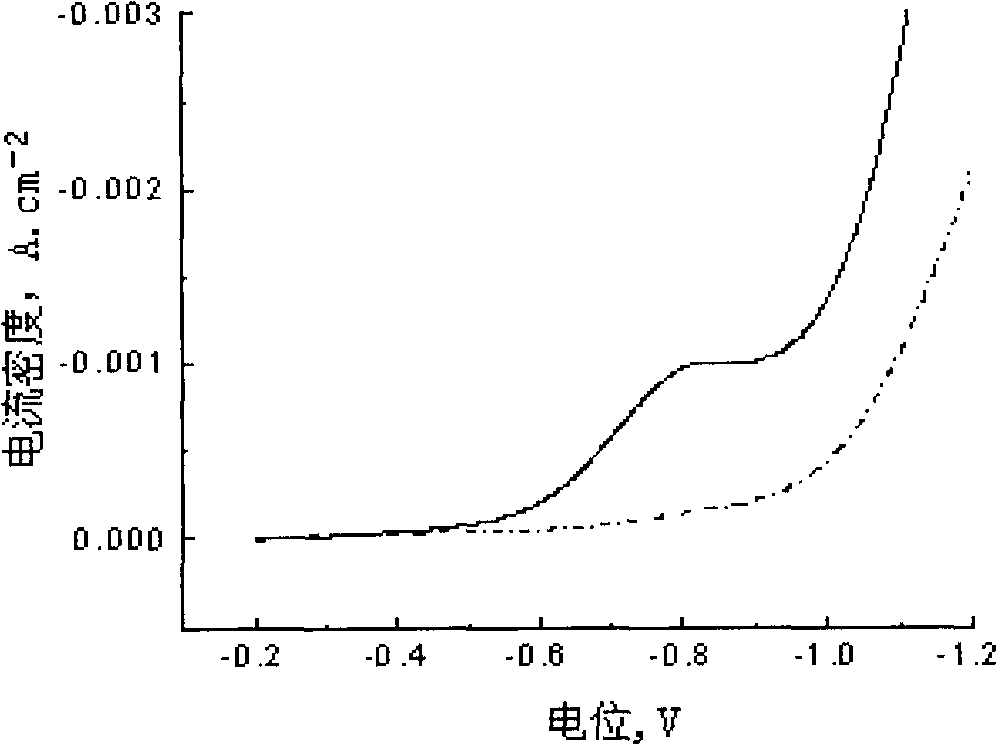

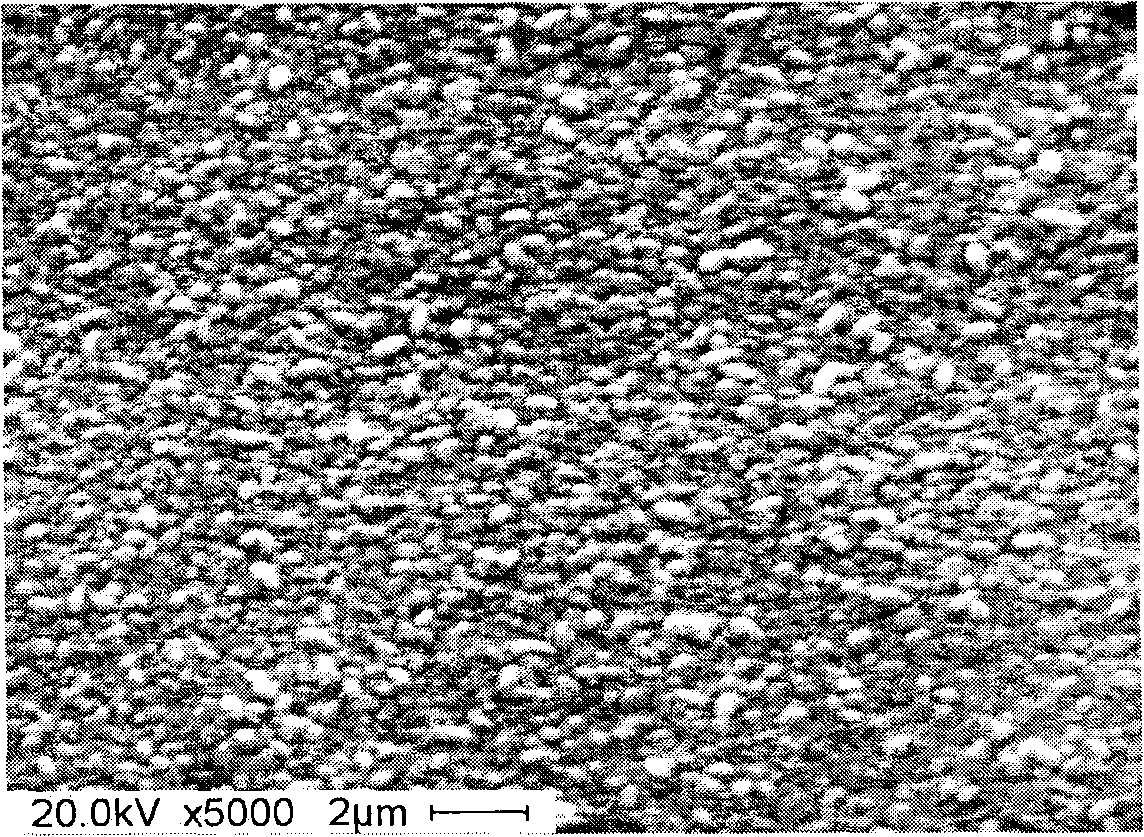

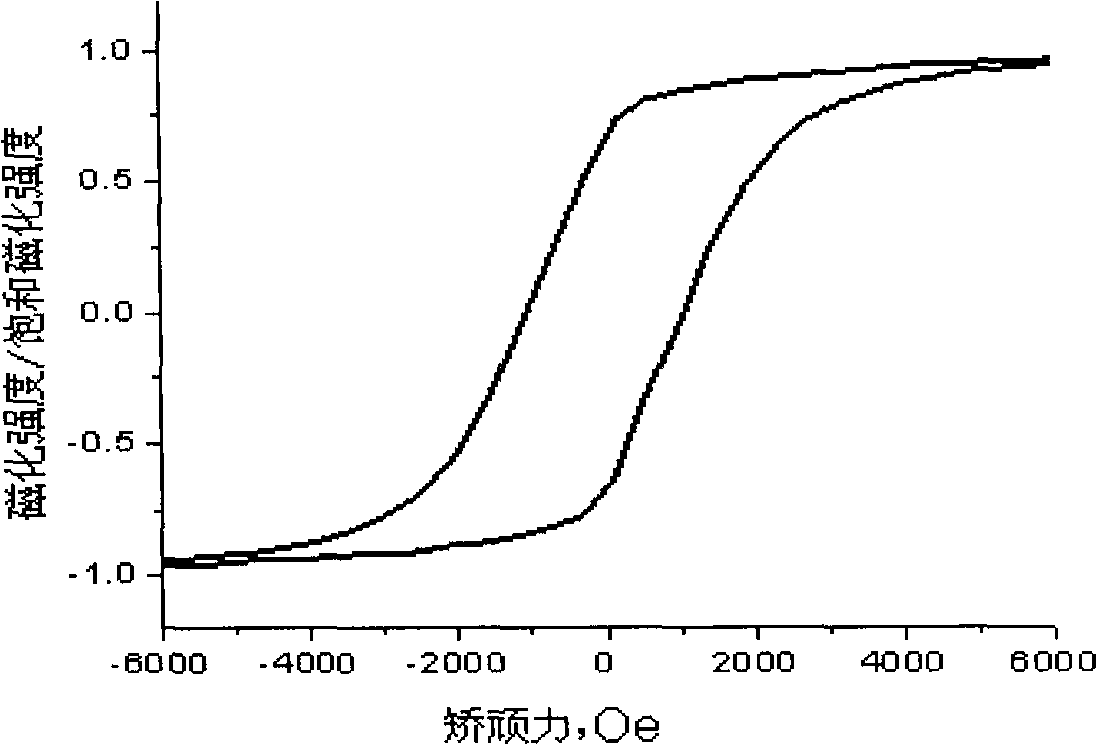

[0033] The plating solution was adjusted to pH=9.0 with ammonia water and hydrochloric acid, and the working electrode was single crystal Si(111) (with HF and HNO at a volume ratio of 3:1 3 Mixed acid etching→washing→air drying), the temperature of the plating solution is 25°C, the time for multilayer palladium plating is 30s, and the time for cobalt plating is 2s. Ammonia exposure test (24 hours at room temperature), no cracks and cracks were observed in the multilayer film. And the magnetic properties of the Co / Pd multilayer film were tested. The hysteresis loop squareness of the Co / Pd metal nano-multilayer film Better, its coercive force can reach 1130 Oe. image 3 shown.

Embodiment 3

[0035] Bath composition

[0036] Dichlorodiamine palladium 3g / L (calculated as Pd)

[0037] Cerium sulfate 0.02g / L (calculated as Ce)

[0038] Ethylenediamine 65mL / L

[0039] Ammonium pyridine-3-sulfonate 0.06g / L

[0040] Sodium sulfate 30g / L

[0041] The plating solution was adjusted to pH=8.5 with ammonia water and hydrochloric acid, and the working electrode was single crystal Si(111) (with HF and HNO at a volume ratio of 3:1 3 Mixed acid etching→washing→air drying), the temperature of the plating solution is 25°C, and the deposition time of multilayer coating Co and Pd is extended to 120s and 600s, respectively. As a result, the layered structure of the Co layer and the Pd layer is clear and continuous. The thickness of the layer is about 120nm and it is shiny. The ammonia exposure test (24 hours at room temperature) of the coated multilayer film has not observed any breakage and cracks in the multilayer film. Figure 4 SEM cross-sectional view of Co / Pd multilayer fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com