Microbial solid inocula, and preparation and use thereof

A solid bacterial agent and microbial technology, applied in the field of FGR solid bacterial agent, can solve the problems of complex preparation process, application limitation, complex production process, etc., achieve high concentration of bacterial liquid cells, save equipment and energy, and fast bacterial cell reproduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

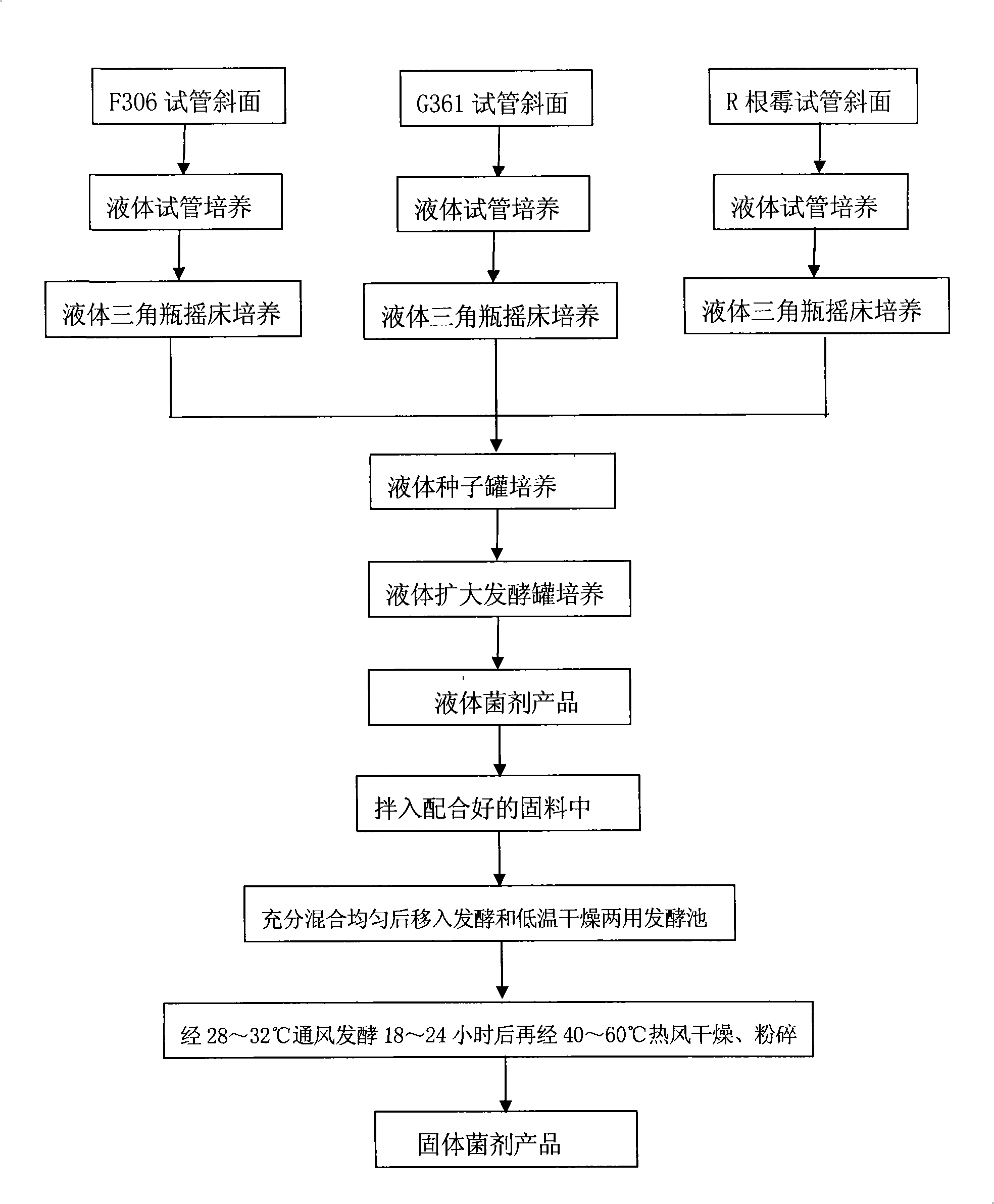

Method used

Image

Examples

Embodiment 1

[0030] (1) Cultivation of liquid strains in test tubes, take fresh tofu waste water and boil for 10 minutes to naturally precipitate to get 100ml of supernatant, add (NH 4 ) 2 SO 4 0.1g, H 3 PO 4 0.05ml, fully dissolved and adjusted to pH 5.5-6.5, packaged in 15×1.5cm dry test tubes, autoclaved at 112°C for 30 minutes, cooled to 32°C, and inoculated with F306 yeast fusion bacteria and G361 Geotrichum candidum respectively , and R. rhizopus in the test-tube liquid medium, cultured at 28-32°C for 24-48 hours, that is, the test-tube liquid strain (first-class strain)

[0031] (2) Cultivation of liquid strains in Erlenmeyer flasks

[0032] Take fresh tofu waste water and boil for 10 minutes to naturally precipitate, take 1000ml of supernatant, add (NH 4 ) 2 SO 4 1g, H 3 PO 4 0.5ml, after fully dissolving, adjust the pH to 5.5~6.5, and pack it into a 500ml Erlenmeyer flask, the amount of which is 1 / 4 of the total amount of the bottle, then autoclave at 112°C for 30 minu...

Embodiment 2

[0039] (1) Cultivation of test tube liquid strains, take 100ml of fresh vermicelli wastewater, add (NH 4 ) 2 SO 4 0.1g, H 3 PO 4 0.05ml, fully dissolved and adjusted to pH 5.5-6.5, packed in 15×1.2cm dry test tubes, sterilized by autoclaving at 112°C for 30 minutes, cooled to 32°C, inoculated with F306 yeast fusion bacteria and G361 Geotrichum candidum respectively , and R. rhizopus in the test-tube liquid medium, cultured at 28-32°C for 24-48 hours, that is, the test-tube liquid strain (first-class strain)

[0040] (2) Cultivation of liquid strains in Erlenmeyer flasks

[0041] Take 1000ml of fresh vermicelli waste water, add (NH 4 ) 2 SO 4 1g, H 3 PO 4 0.5ml, after fully dissolving, adjust the pH to 5.5~6.5, and pack it into a 500ml Erlenmeyer flask, the amount of which is 1 / 4 of the total amount of the bottle, then autoclave at 112°C for 30 minutes, cool to 32°C, The test-tube liquid strain is inoculated into the liquid conical flask medium, and cultured at 28...

Embodiment 3

[0048] (1) Cultivation of liquid strains in test tubes, take fresh cornstarch wastewater, boil for 10 minutes to get natural precipitation to take 100ml of supernatant, add (NH 4 ) 2 SO 4 0.1g, H 3 PO 4 0.05ml, fully dissolved and adjusted to pH 5.5-6.5, packed in 15×1.2cm dry test tubes, sterilized by autoclaving at 112°C for 30 minutes, cooled to 32°C, inoculated with F306 yeast fusion bacteria and G361 Geotrichum candidum respectively , and R. rhizopus in the test-tube liquid medium, cultured at 28-32°C for 24-48 hours, that is, the test-tube liquid strain (first-class strain)

[0049] (2) Cultivation of liquid strains in Erlenmeyer flasks

[0050] Get fresh cornstarch wastewater, get 1000ml of supernatant after boiling for 10 minutes, and add (NH) 4 ) 2 SO 4 1g, H 3 PO 4 0.5ml, after fully dissolving, adjust the pH to 5.5~6.5, and pack it into a 500ml Erlenmeyer flask, the amount of which is 1 / 4 of the total amount of the bottle, then autoclave at 112°C for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com