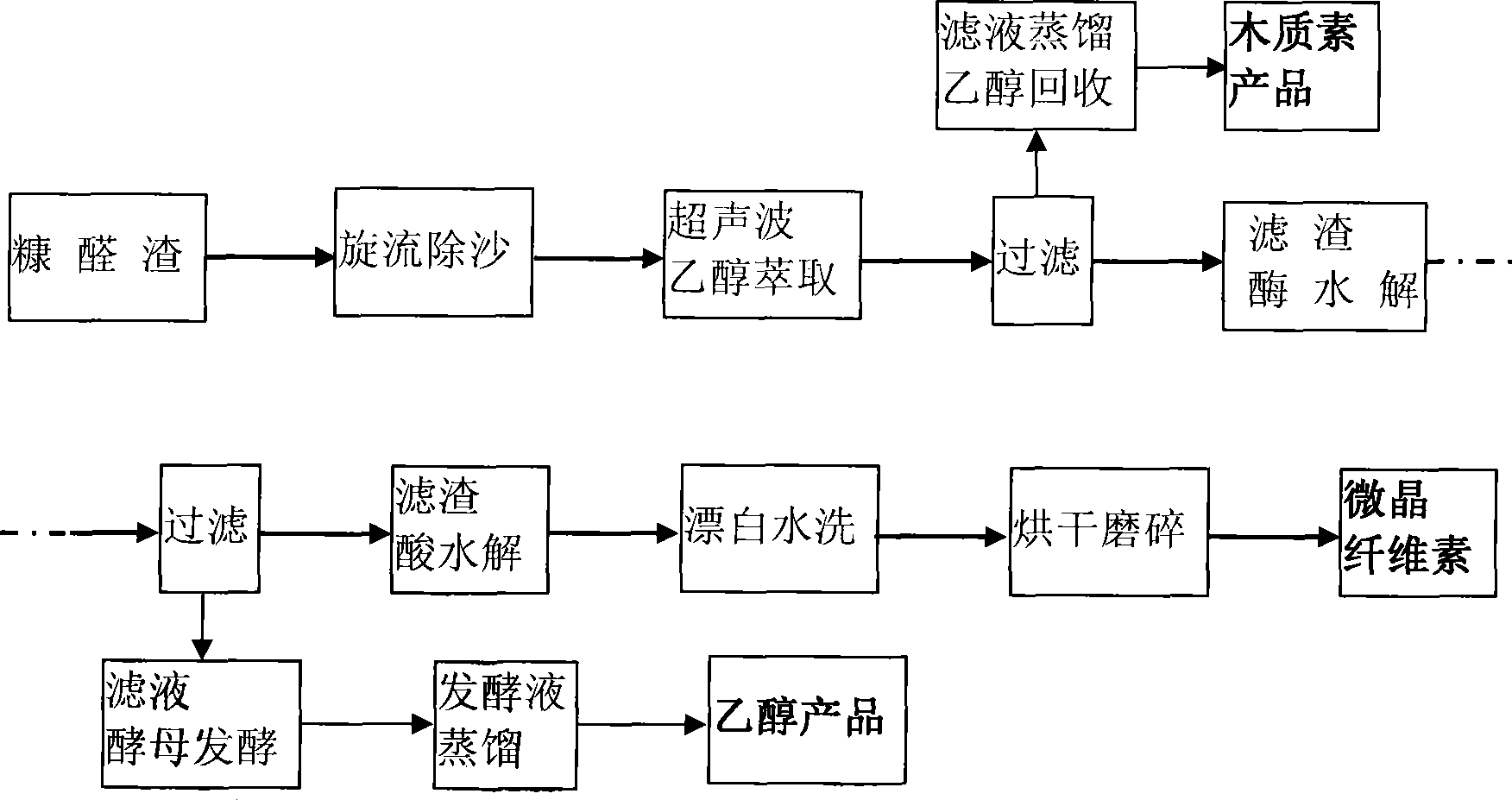

Method for preparing microcrystalline cellulose and cellulose fuel ethanol by separating furfural residue

A technology of microcrystalline cellulose and cellulosic ethanol, which is applied in the directions of biochemical equipment and methods, microorganism-based methods, and fiber raw material processing, etc., can solve the problem of high cost, achieve short action time, reduce production cost, and high product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The aqueous solution of furfural slag with a mass concentration of 10% is desanded through a cyclone desander, and the feed pressure is 0.45 MPa.

[0034] Using ethanol solution with a mass concentration of 55% as the extraction solvent, ultrasonic extraction method is used for lignin extraction and separation. The ratio is 15:1; the extraction temperature is 120°C, and the extraction cycle time is 50min.

[0035] The extracted material was filtered, the filtrate was distilled under reduced pressure at 50°C to recover ethanol, and the distillation residue was vacuum-dried at 50°C to obtain a lignin product with a product yield of 34.7%;

[0036] Add the endoglucanase / (g cellulose) of 12 international units and the β-glucosidase / (g cellulose) of 10 international units in the raffinate residue and pack into enzymolysis reactor, the substrate quality The concentration is 6%, the enzymolysis reaction temperature is 45° C., the enzymolysis reaction pH value is 4.5, and the ...

Embodiment 2

[0041] The aqueous solution of furfural slag with a mass concentration of 10% is desanded through a cyclone desander, and the feed pressure is 5kgf / cm 2 .

[0042] Using ethanol as solvent, lignin is extracted and separated by ultrasonic extraction method. The ultrasonic frequency is 30khz, the ultrasonic power is 280W, the interval of ultrasonic action is 5min, and each action time is 3min; The mass ratio is 20:1; the extraction temperature is 70°C, and the extraction cycle time is 130min.

[0043] The extracted material was filtered, the filtrate was distilled under reduced pressure at 50°C to recover ethanol, and the distillation residue was vacuum-dried at 50°C to obtain a lignin product with a product yield of 31.6%.

[0044] Add the endoglucanase / (g cellulose) of 12 international units and the β-glucosidase / (g cellulose) of 10 international units in the raffinate residue and pack into enzymolysis reactor, the substrate quality The concentration is 10%, the enzymolysis ...

Embodiment 3

[0049] The aqueous solution of furfural slag with a mass concentration of 10% is desanded through a cyclone desander, and the feed pressure is 4.8kgf / cm 2 .

[0050] Use ethanol as solvent to extract and separate lignin by ultrasonic extraction method, ultrasonic frequency 40khz, ultrasonic power 200W, ultrasonic action interval 8min, each action time 4min; the mass concentration of the ethanol solution of the extract is 75%, the ethanol solution and furfural residue The mass ratio is 7:1; the extraction temperature is 100°C, and the extraction cycle time is 90 minutes.

[0051] The extracted material was filtered, the filtrate was distilled under reduced pressure at 60°C to recover ethanol, and the distillation residue was vacuum-dried at 55°C to obtain a lignin product with a yield of 33.2%.

[0052] Add the endoglucanase / (g cellulose) of 12 international units and the β-glucosidase / (g cellulose) of 10 international units in the raffinate residue and pack into enzymolysis r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com