1- MCP/modified stabilizer coating material, production method and use thereof

A technology of methylcyclopropene and stabilizer, which is applied in the field of 1-methylcyclopropene, can solve the problems of shortening the storage and transportation validity period of preservatives, the influence of external temperature and humidity, and the reduction of partial pressure concentration, etc., so as to improve the gaseous state Stability, low cost, effect of reducing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 500ml of loading solution (pH value 3) of acetic acid and sodium acetate mixed solution in the loader, play molecular lock effect soluble salt mixture (calcium sulfate and sodium carbonate each 10g), then add 100g modified stabilizer modified starch ( YD starch), seal the loader, vacuumize, blow N2 gas to drive out the air, put the loader into an ice-water bath, control the temperature at 4°C-8°C, start stirring, the loader pressure is about 0.03Mpa, put 1-formazol The methylcyclopropene gas is passed into the loader, and the 1-methylcyclopropene in the tail gas of the loader is sent to the nitrogen-enriched membrane treatment device for enrichment treatment, and then recycled to ensure that the 1-methylcyclopropene in the raw material gas is absorbed and reacted for 10 hours. The concentration of methylcyclopropene is relatively stable, and a mixture of 1-methylcyclopropene / modified stabilizer is formed, and the material loading liquid is released, centrifuged and d...

Embodiment 2

[0035] Synthesis of 1-methylcyclopropene: In a 1000ml reaction vessel, vacuumize, fill nitrogen with slight positive pressure, add 400ml of dry tetrahydrofuran, 160g of sodium amide, start stirring, start condensing and reflux, slowly raise the temperature to 62°C, and start slowly dripping Add 100 g of 3-chlorodimethylpropene. After the dropwise addition, continue to stir for 80min;

[0036] N through bubbler 2(The bubbler is inserted into the reaction solution), carry out the gas stripping operation, and put forward the product gas 1-methylcyclopropene stably, and after the by-products such as ammonia gas and impurities are gas-washed by three gas scrubbers, they are sent to the nitrogen-enriched Membrane treatment device;

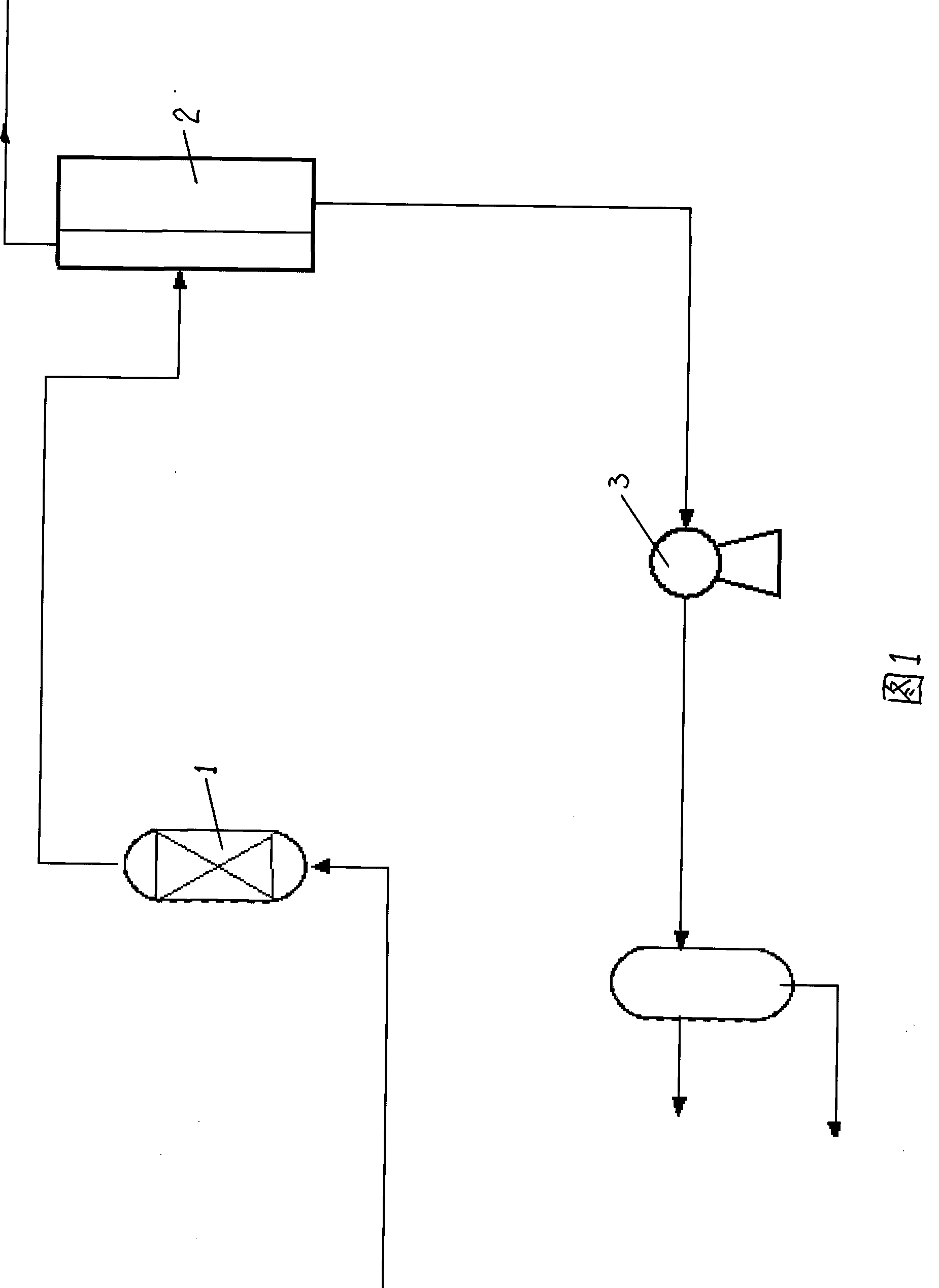

[0037] The flow chart of the nitrogen-rich membrane treatment device is shown in Figure 1. The product gas enters the membrane separation device after passing through the cleaner 1, and the operating pressure difference is 800KPa. The nano-membrane sep...

Embodiment 3

[0042] According to the preparation method of Example 2, 1-methylcyclopropene / modified stabilizer inclusions were prepared:

[0043] Synthesis of 1-methylcyclopropene: 300g of lithium diisopropylamide as raw material, slowly raise the temperature to 35°C, start to slowly add 300g of 3-chlorodimethylpropene dropwise, after the dropwise addition, continue to stir for 100min, and process with nitrogen-enriched membrane The operating pressure difference is 600KPa, and the product gas concentration is increased by 28%.

[0044] The load of 1-methylcyclopropene: the load liquid 500ml (pH value 6) of acetic acid and sodium acetate mixed solution, each 8g of soluble salt ammonium carbonate, sodium carbonate, the syngas concentration before entering loader is 38% (volume), The modified stabilizer is 50 g of modified starch, 20 g of methyl β-cyclodextrin, and 10 g of α-cyclodextrin. After circulating and absorbing for 3 hours, the concentration drops to 23%. After being sent to the nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com