Method for preparing oxidized starch modified vinyl acetate-acrylate latex

A technology of oxidizing starch and acetic acid acrylic emulsion, applied in the directions of starch-derived adhesives, adhesive types, monocarboxylic acid ester copolymer adhesives, etc., can solve problems such as water resistance not mentioned, application and promotion restrictions, etc. Achieve the effect of increasing solid content, reducing free monomer content and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

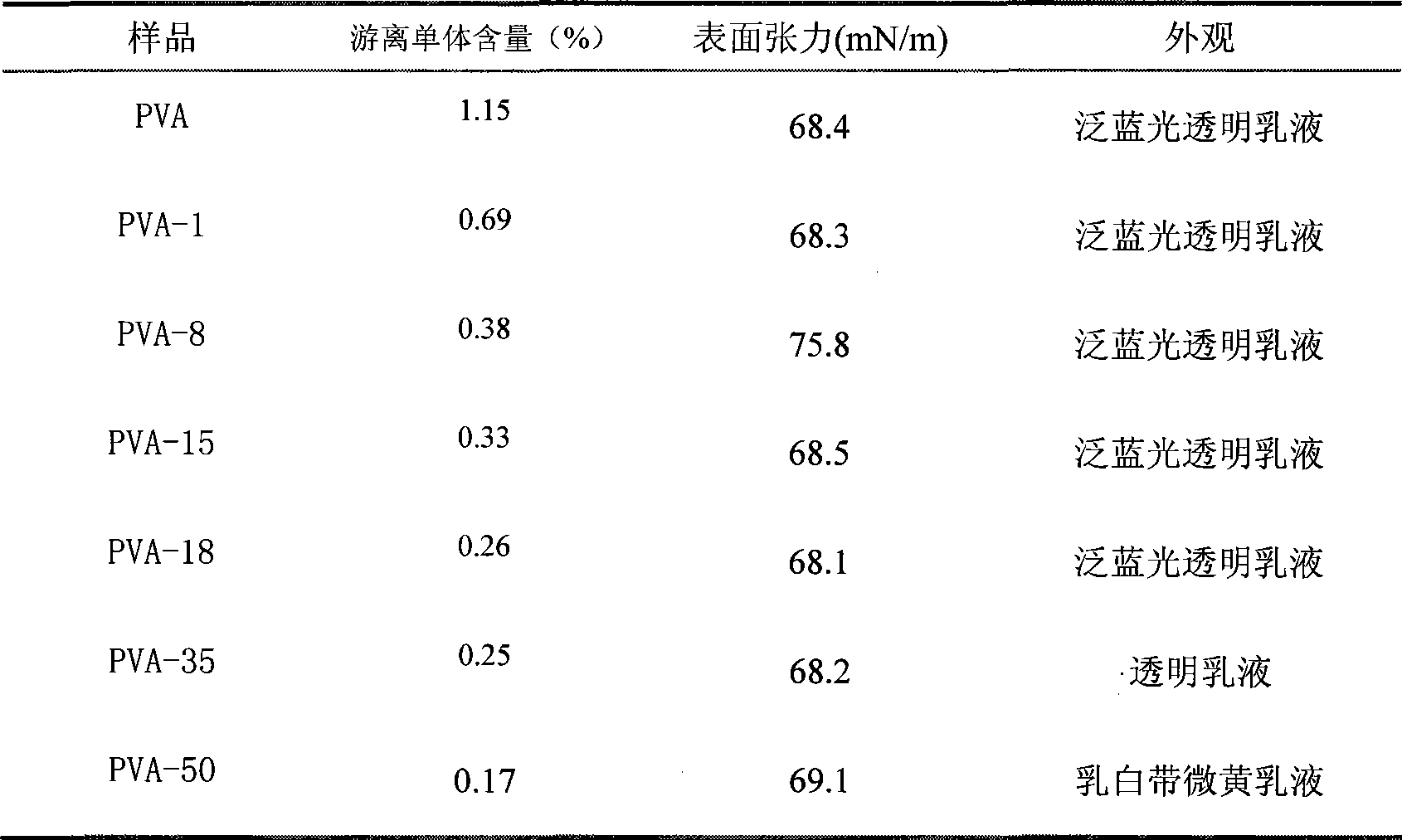

Embodiment 1

[0018] Add 0.04g of anionic emulsifier K 12 , 0.4g of non-ionic emulsifier Span and 853g of deionized water were emulsified for 10min, and under strong stirring, 0.4g of vinyl acetate and 0.04g of acrylic acid were added as seed monomers and 0.44g of perchloric acid oxidized starch to form a transparent seed microemulsion. Slowly raise the temperature to 40°C, add 0.04g of ammonium persulfate to initiate microemulsion polymerization, and slowly add the remaining 39.6g of vinyl acetate and 3.96g of acrylic acid dropwise after the emulsion turns blue, and finish the dripping within 4 hours, keep warm at 60°C for 6 hours, and then use 0.00055g sodium hydroxide regulates the system pH value to 6.5, stops heating after continuing to stir for 15min, cools and discharges, and obtains the vinegar-acrylic polymer emulsion PVA-1 (wherein the oxidized starch is modified by 5% translucent oxidized starch) with a solid content of 5%. Linked starch quality accounts for 1% of the acetate pro...

Embodiment 2

[0020] Add 6g of anionic emulsifier SDS, 2g of nonionic emulsifier Tween, and 192g of deionized water into a 500mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer, and feeding device for emulsification for 1 hour, and add 9g of vinyl acetate and 6g of methyl methacrylate was used as the seed monomer and 8g of potassium permanganate oxidized starch to prepare a transparent seed microemulsion. Slowly raise the temperature to 82°C, add 1.8g of potassium persulfate to initiate microemulsion polymerization, and slowly add the remaining 51g of vinyl acetate and 34g of methyl methacrylate dropwise after the emulsion turns blue, and finish the dripping within 2 hours, then keep warm at 92°C for 1.5h , then adjust the pH value of the system to 8.9 with 3g ammonium bicarbonate, stop heating after continuing to stir for 15min, and cool the discharge to obtain a translucent oxidized starch modified vinegar-acrylic polymer emulsion PVA-8 (wherein the solid content ...

Embodiment 3

[0022] Add 6g of anionic emulsifier SDS, 3g of nonionic emulsifier OP-10 and 331g of deionized water into a 1000mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device for 30 minutes, and add 10g of vinyl acetate under strong stirring ester and 5g butyl acrylate as seed monomer and hydrogen peroxide oxidized starch 15g to form a transparent seed microemulsion. Slowly raise the temperature to 75°C, add 4.5g of potassium persulfate to initiate microemulsion polymerization, and slowly add the remaining 90g of vinyl acetate and 45g of butyl acrylate dropwise after the emulsion turns blue, and finish the dripping within 1.5h, keep warm at 88°C for 1h, and then Regulate system pH value to 9.5 with 0.03g ammoniacal liquor, stop heating after continuing to stir for 15min, cool and discharge, obtain the vinegar-acrylic polymer emulsion PVA-15 (wherein oxidative cross-linking The starch quality accounts for 15% of the acetate propylene polymer). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com