Method for the production of bio-imaging nanoparticles with high yield by early introduction of irregular structure

A nanoparticle and biological imaging technology, applied in nanostructure manufacturing, nanotechnology for materials and surface science, nanomedicine, etc., can solve the problem of low reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

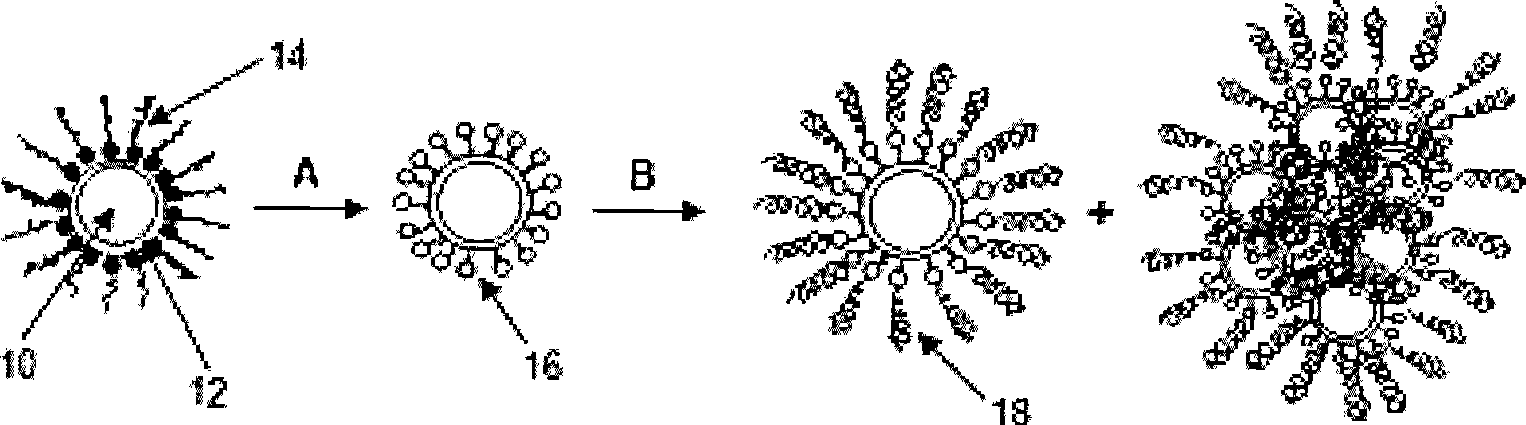

Method used

Image

Examples

Embodiment 1

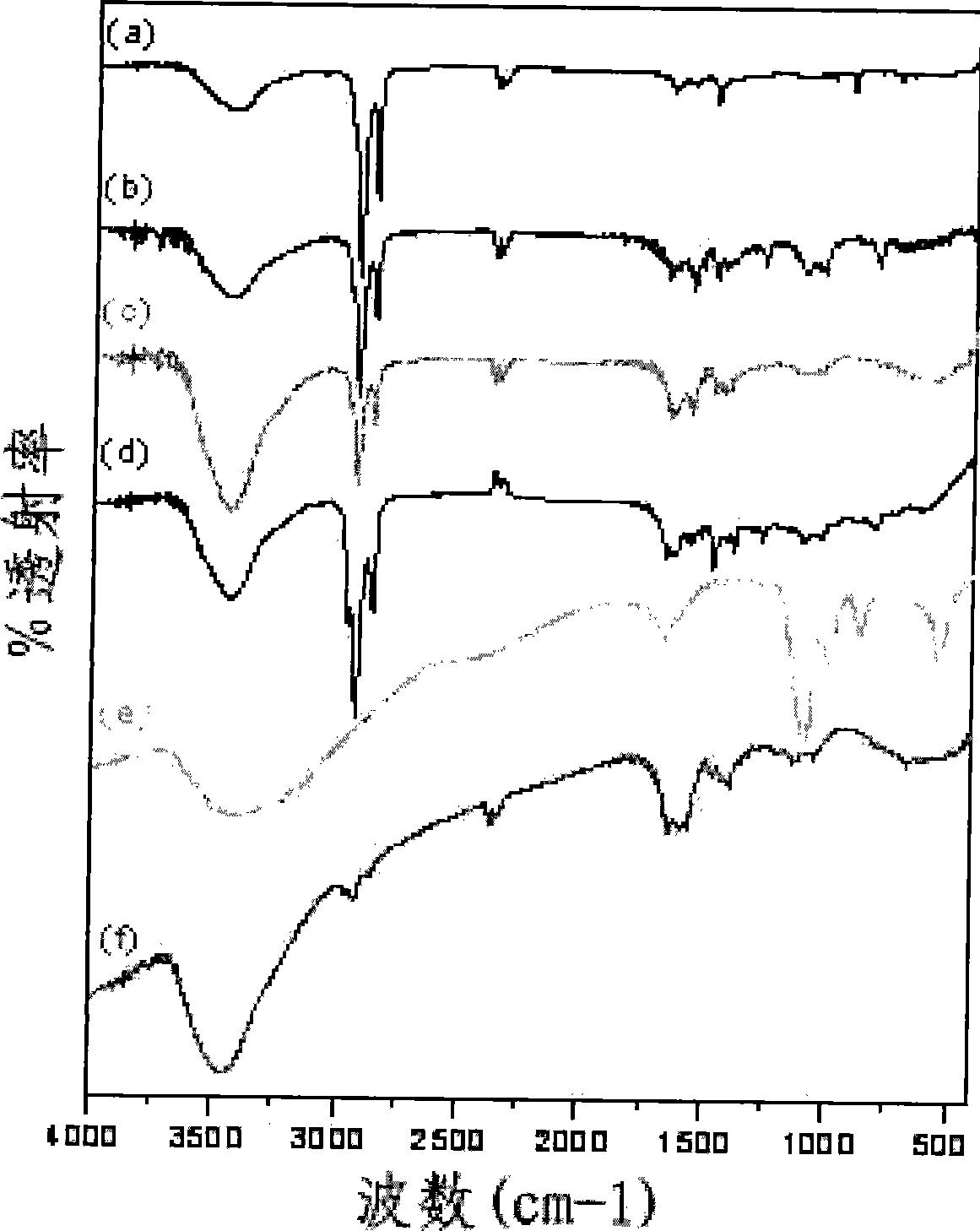

[0064] Example 1: Preparation of semiconductor nanoparticles CdSe / CdS-DA by surface ligand exchange

[0065] Vacuum evaporation of 5ml CdSe / CdS-ODA hydrophobic quantum dot solution (8 × 10 -5 M) to remove the solvent and disperse in 20ml of chloroform. To this dispersion was added 1000 equivalents of decylamine (DA) and the mixture was stirred for 2 days in a dark inert atmosphere. The resulting solution was mixed with acetone and centrifuged to separate the precipitate. The thus prepared precipitate was dispersed in chloroform to prepare 20ml of CdSe / CdS-DA solution (2×10 -5 M). The CdSe / CdS-DA samples were analyzed by infrared spectrometer and transmission electron microscope (TEM), where the image 3 (b) and Figure 4 The results are shown in (b). The exchange of surface ligands was confirmed by the shorter distance between CdSe / CdS-DA quantum dots than CdSe / CdS-ODA in the TEM images.

Embodiment 2

[0066] Example 2: Preparation of partially surface-modified semiconductor nanoparticles CdSe / CdS(-DA)ex(-MUA)

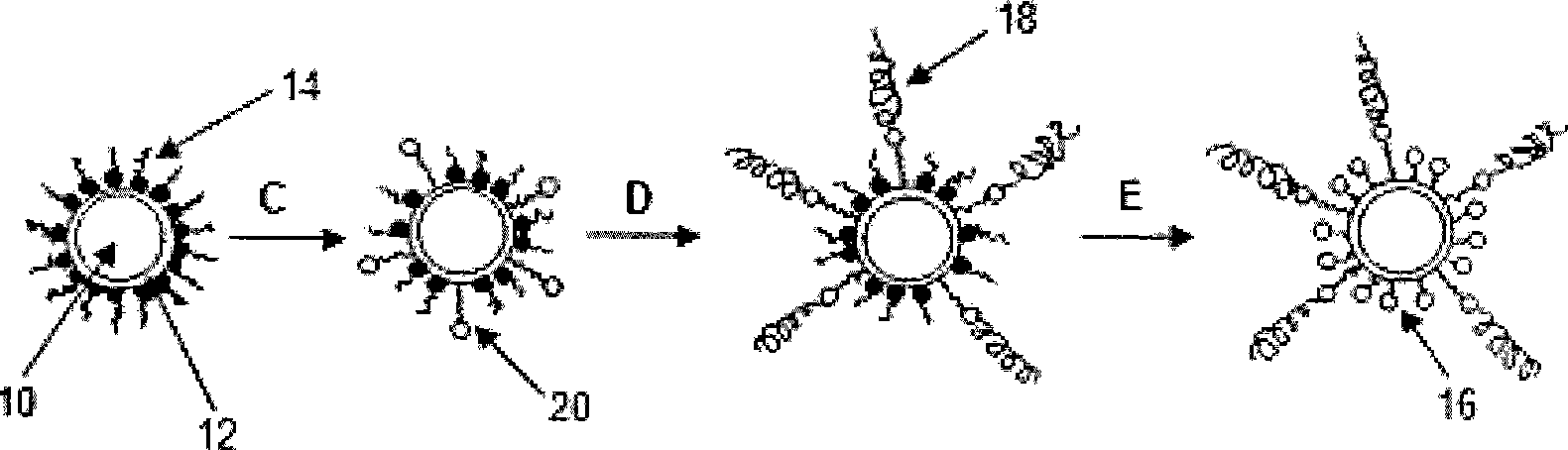

[0067]Add 5 equivalents of mercaptoundecanoic acid (MUA) to 17 ml of the CdSe / CdS-DA solution prepared in Example 1, and stir for 19 hours in a dark inert atmosphere. The resulting solution was concentrated, mixed with acetone, and the precipitate was separated by centrifugation. The thus prepared precipitate was dispersed in chloroform to prepare 17ml of CdSe / CdS(-DA)ex(-MUA)5 solution (2×10 -5 M). The obtained samples were analyzed by infrared spectrometer and transmission electron microscope (TEM), in which image 3 (c) and Figure 4 The results are shown in (c). The TEM images confirmed that the self-assembly of the nanoparticles no longer occurred, which was attributed to the disruption of their homogeneous structure caused by the partial replacement of MUA, as figure 2 as shown in step C.

Embodiment 3

[0068] Example 3: Preparation of targeted hydrophobic semiconductor nanoparticles CdSe / CdS(-DA)ex(-MUA-en-FA)5

[0069] 2 ml of the CdSe / CdS(-DA)ex(-MUA)5 solution prepared in Example 2 was diluted with chloroform to a final volume of 10 ml. After adding 5 equivalents of dicyclohexylcarbodiimide (DCC) to the diluent and stirring for 3 hours in a dark inert atmosphere, 50 equivalents of en-FA prepared as described below was added thereto and stirred for a further 2 hours . The resulting solution was concentrated, mixed with acetone, and the precipitate was separated by centrifugation. The thus prepared precipitate was dispersed in chloroform to prepare 10 ml of CdSe / CdS(-DA)ex(-MUA-en-FA)5 solution (4×10 -6 M). The binding of en-FA to MUA was analyzed by infrared spectrometer and TEM, where respectively in image 3 (d) and Figure 4 The results are shown in (d).

[0070] Preparation of complex en-FA targeting molecule folic acid (FA) and ethylenediamine (en)

[0071] 441...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com