Liquid electrode surface discharge plasma reactor for water treatment

A technology of liquid electrode and surface discharge, applied in the direction of electrochemical water/sewage treatment, etc., can solve the problems of temperature rise, reduction of ozone production, poor treatment effect, etc., and achieve low one-time investment, high water treatment effect, and operation The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

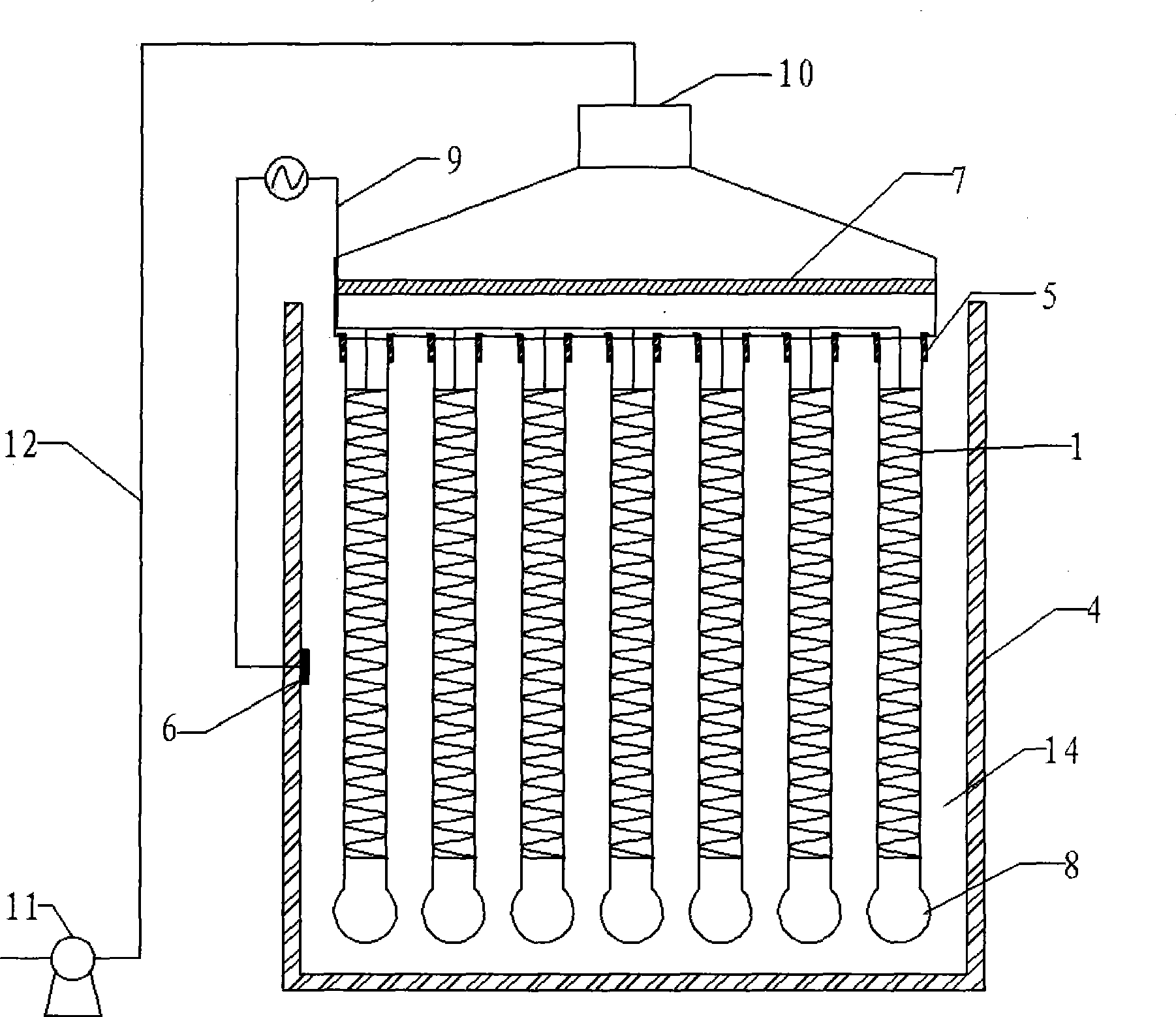

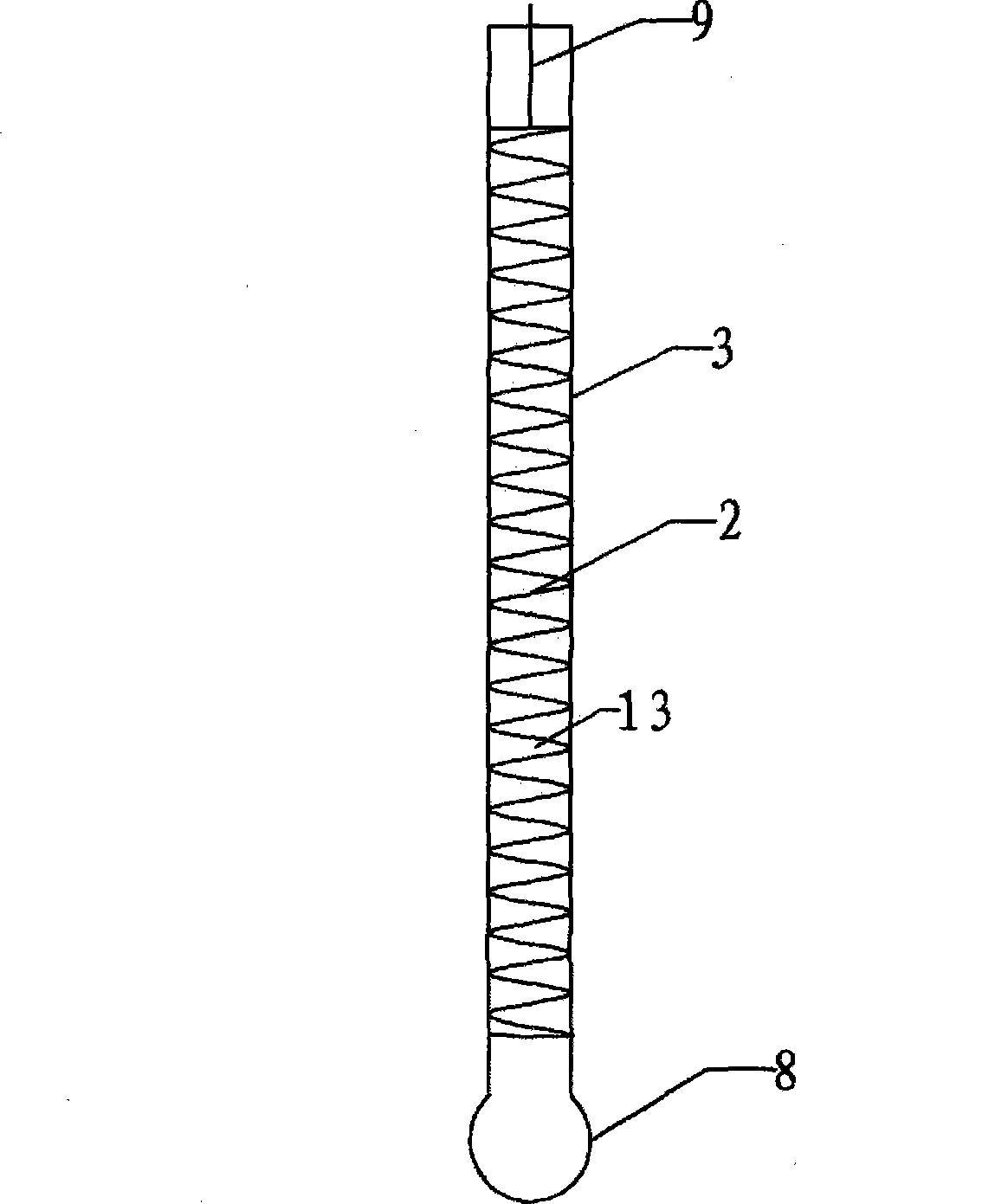

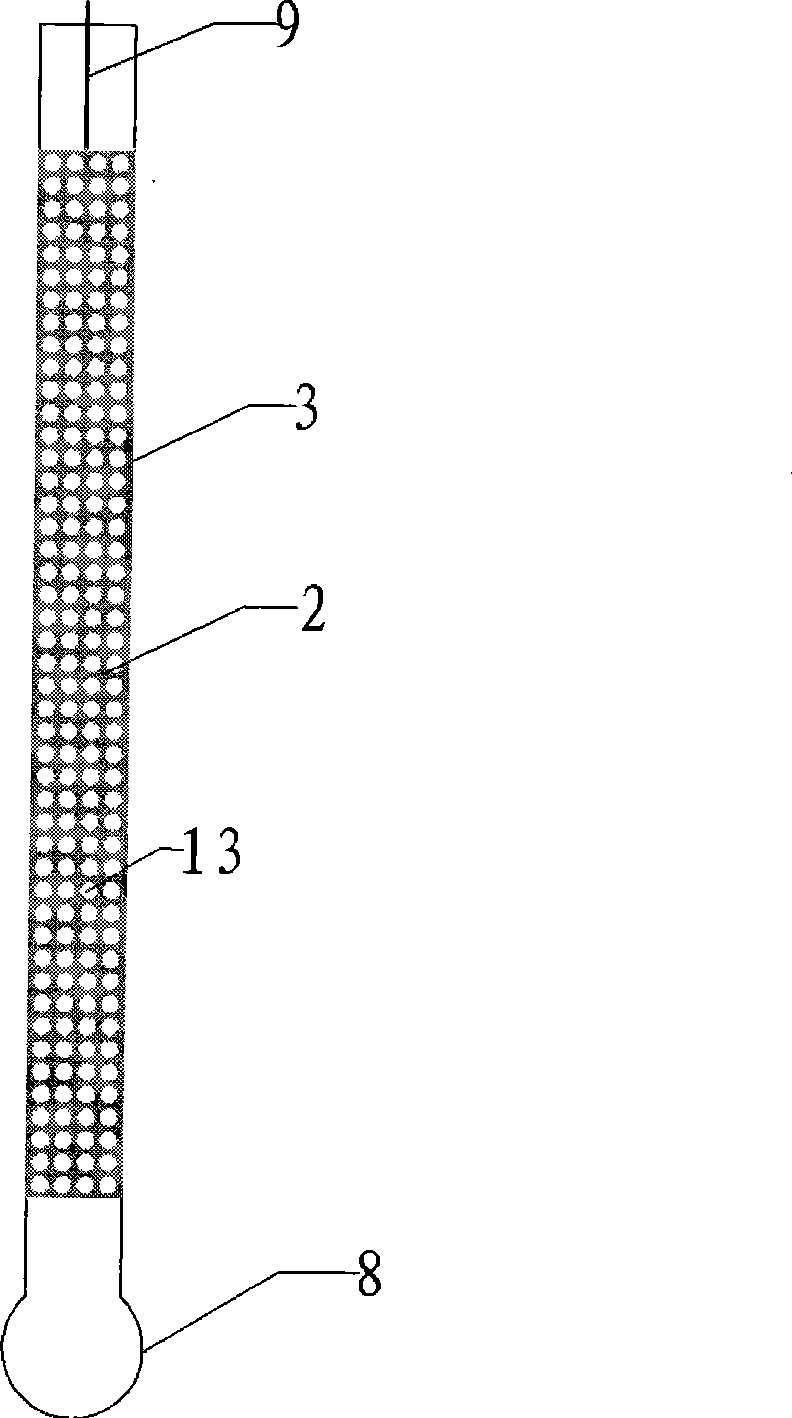

[0013] As shown in the drawings: the present invention mainly consists of a water tank 4, a discharge electrode system 1 and a waste water area 14, and the discharge electrode system 1 is placed in the center of the water tank 4. The discharge electrode system 1 is composed of multiple insulating dielectric tubes 3 lined with high-voltage discharge electrodes 2 connected in parallel. On the inner wall of the insulating medium tube 3, ceramic materials with high dielectric strength, quartz glass or mica are used. An insulator 5 is installed at the upper port of each insulating dielectric tube 3. There are gas inlets and high-voltage cable 9 outlets on the insulator 5, and the lower port Connect the aeration head 8, one end of the high-voltage cable 9 is connected to the high-voltage discharge electrode 2, and the other end is connected to the high-voltage terminal of the AC high-voltage power supply, all insulating medium tubes are installed on the frame of the discharge electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com