Leaching-ore bacteria and high temperature heap bioleaching process for chalcopyrite ore by using the same

A technology for copper sulfide ore and biological heap, which is applied to the improvement of process efficiency, bacteria and other directions, can solve the problems of poor economic benefits and no economic benefits, and achieves the improvement of comprehensive utilization level, biological heap leaching efficiency, and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

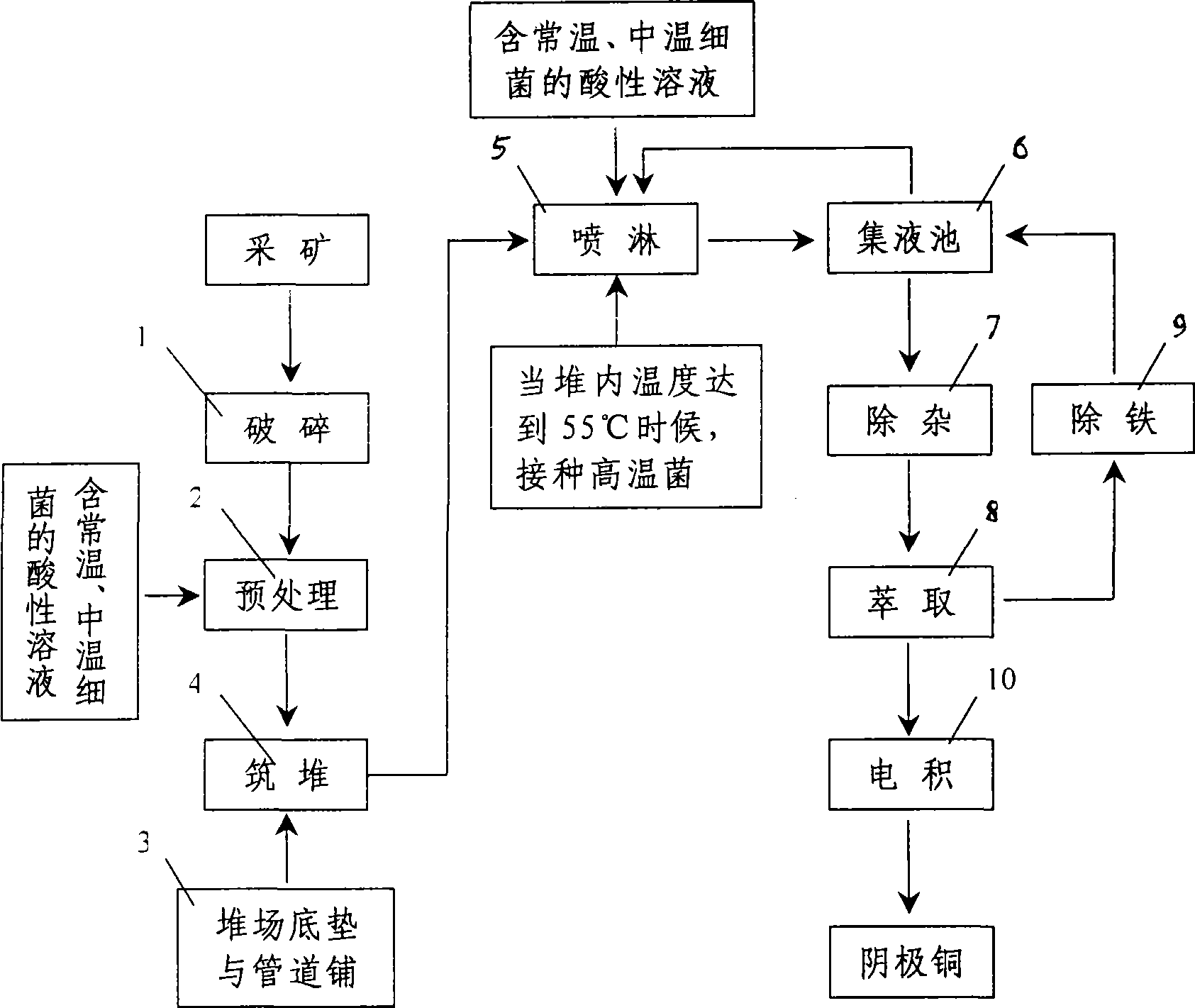

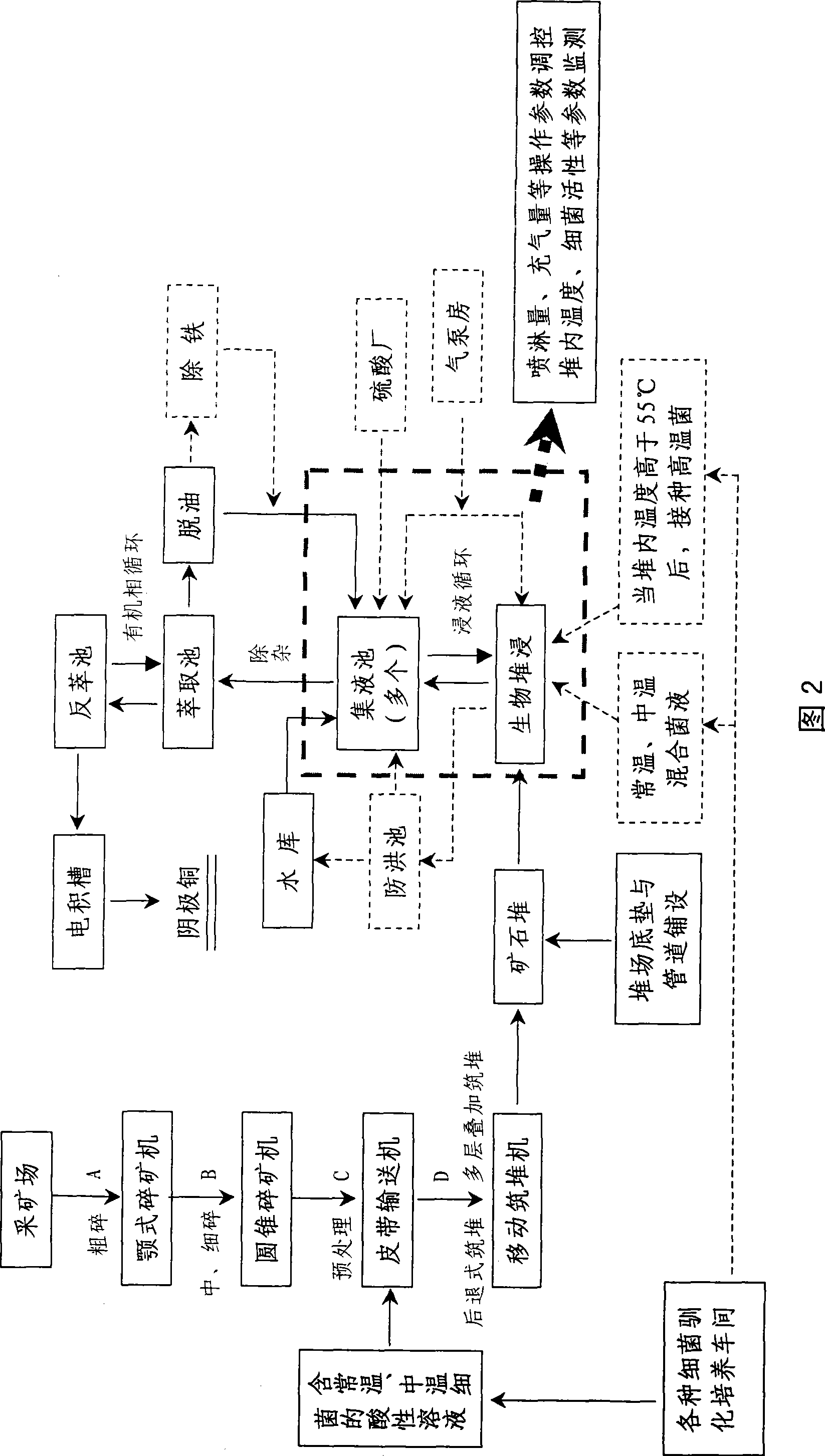

Method used

Image

Examples

Embodiment 1

[0039] The main copper mineral in a domestic copper mine is primary copper sulfide ore (85.96% occupancy), containing a small amount of secondary copper sulfide ore (9.69% occupancy) and copper oxide ore (4.85% occupancy). The total copper content in the ore was 1.65%. The ore is a sulfide ore with pyrite as the matrix mineral. Most of the iron and sulfur in the ore together form iron sulfide minerals - pyrite, pyrrhotite, marcasite and colloid pyrrhotite, and a small part of iron Iron oxide minerals - magnetite, hematite, limonite, and some iron is distributed in carbonate minerals and aluminosilicate minerals in the form of impurities; gangue minerals mainly include quartz, feldspar, green Mudstone, sericite and carbonate minerals - calcite, dolomite, and useful mineral chalcopyrite are distributed in sulfide minerals and gangues in different shapes and sizes.

[0040] The present invention will be further described below in conjunction with specific implementation examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com