Method for preparing low-oxygen aluminum nitride powder by auto-igniting synthesis

A low oxygen content, self-propagating combustion technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of incapable of large-scale production process, high oxygen content and complexity of powder, and achieve rapid synthesis reaction time , high purity and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

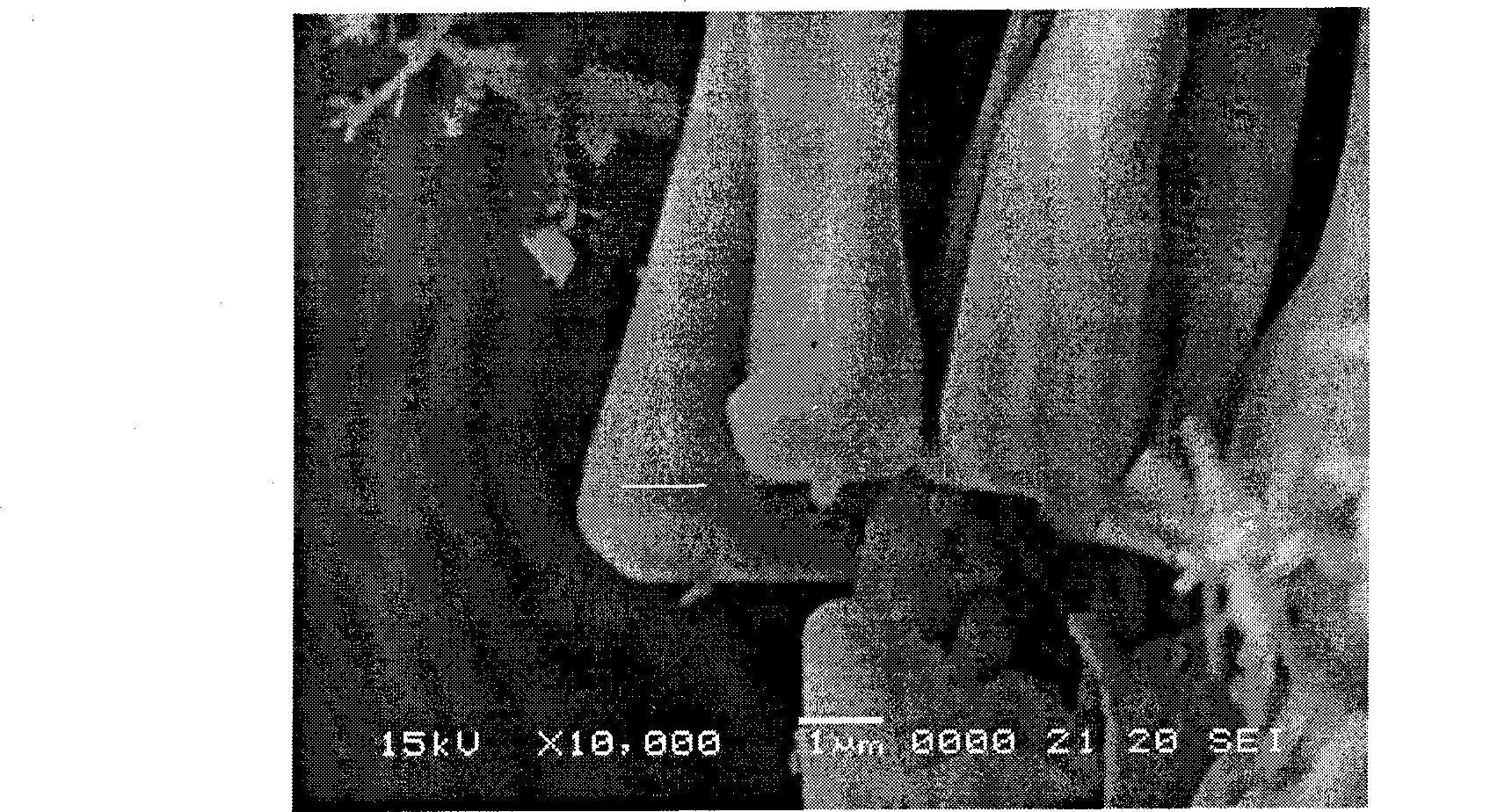

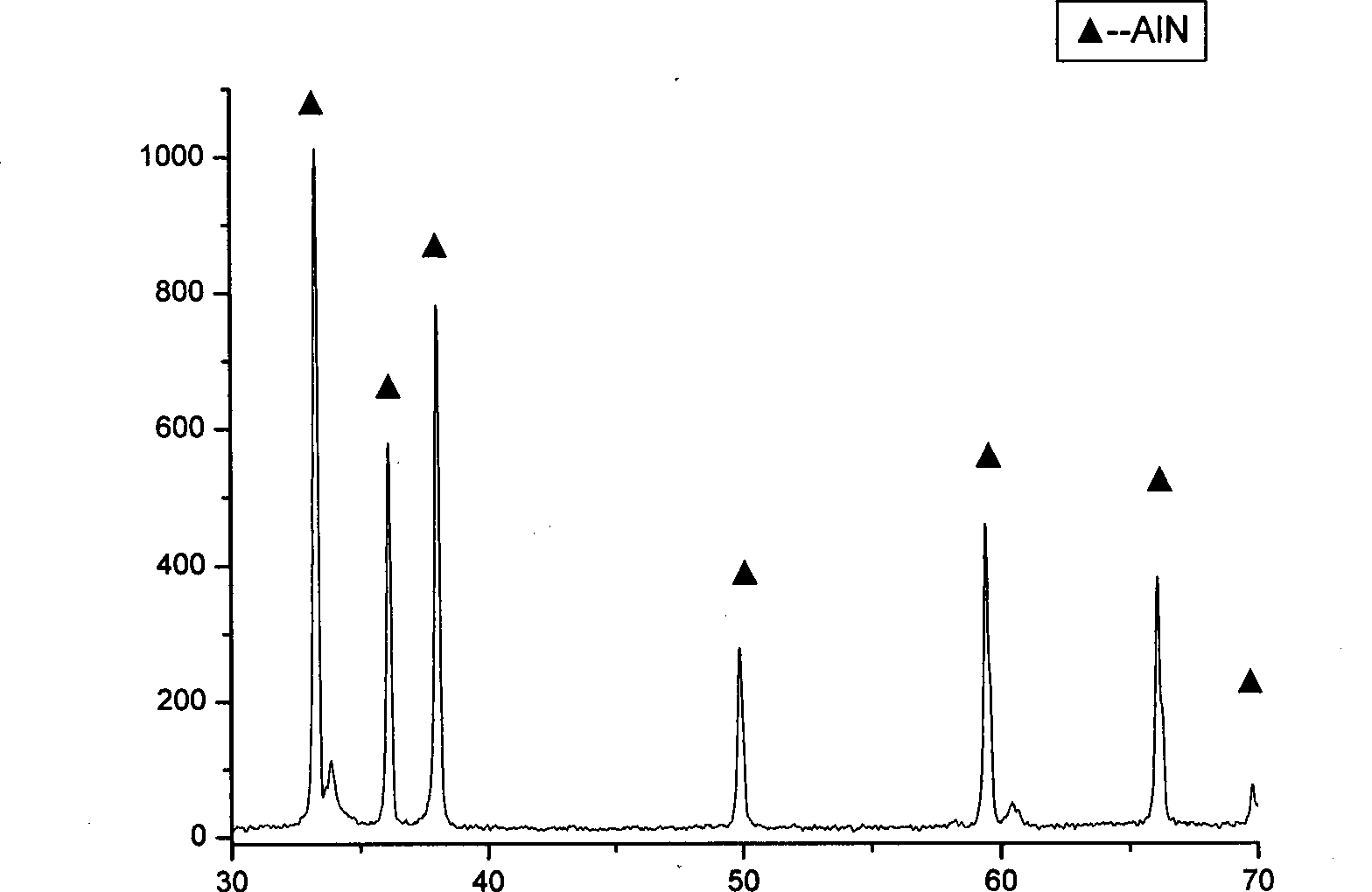

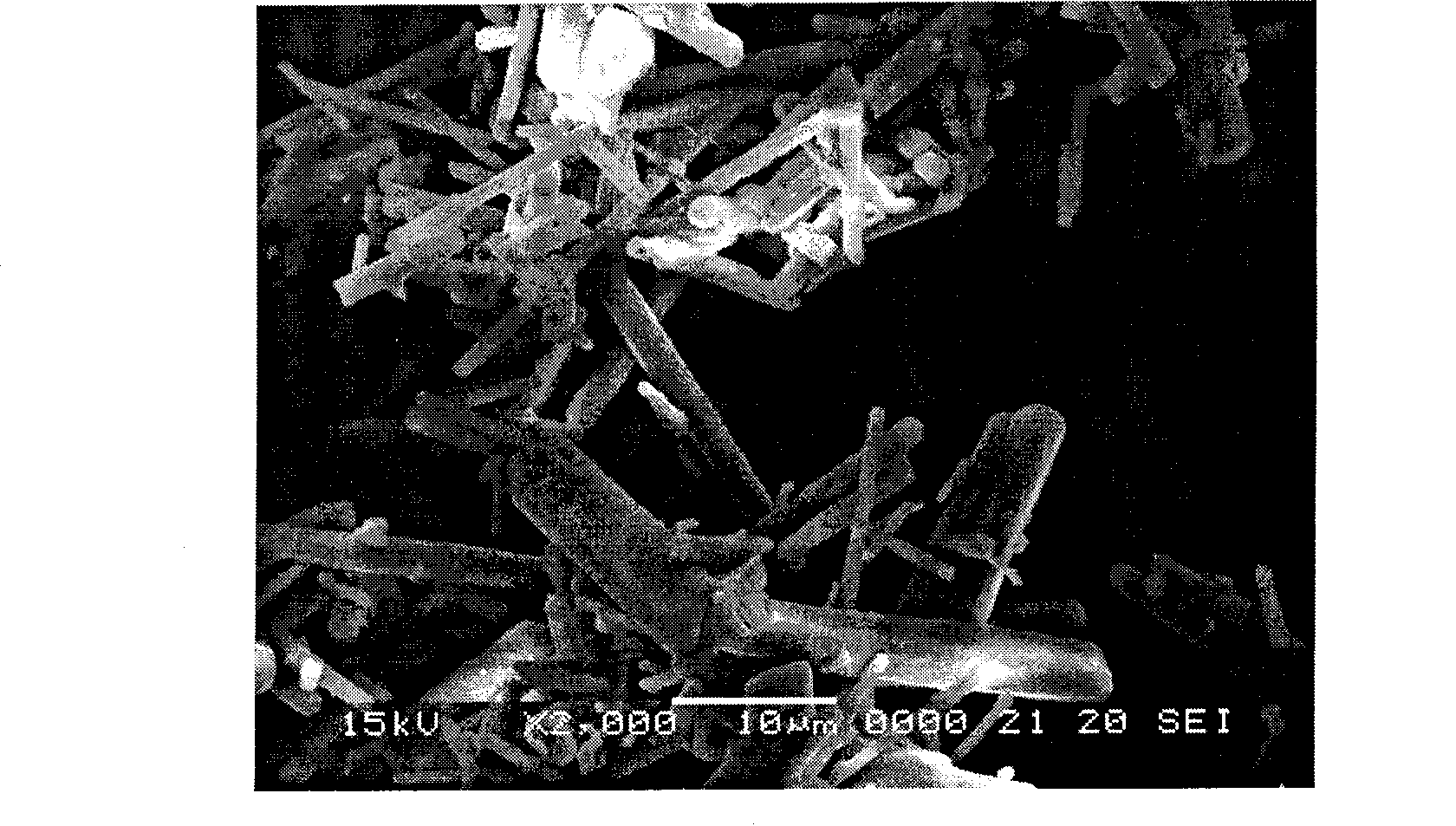

[0032] Embodiment 1, selects particle size to be 300 purpose metal aluminum powders (the purity of metal aluminum powder >99.5%, iron content98.8%) 50%, NH4 Cl5wt% is mixed and put into the tank mill, which is lined with polyurethane and Al 2 o 3 The ball is the ball milling medium, the material: ball weight ratio is 1:4, and the ball milling takes 2 hours. The powder after ball milling passes through a 40-mesh sieve, and the sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then flat Put it into a self-propagating combustion synthesis reactor, after vacuuming, fill it with high-purity nitrogen to 2MPa, and then exhaust it. This process is repeated 3 times, and then fill it with high-purity nitrogen until the pressure is kept at 3MPa. Use a tungsten wire with a diameter of 0.6mm as the The heating element is fed with a current of 25 amps, and the ignition time lasts for 15 seconds. The ignition induces the raw material powder to undergo a self-pr...

Embodiment 2

[0033] Embodiment 2, select particle size to be 200 mesh metal aluminum powders (the purity of metal aluminum powder >99.5%, iron content4 Cl 15wt% and sodium azide 5wt% are mixed and put into a three-dimensional motion mixer. The inside of the mixer is lined with polyurethane and Al 2 o 3 The ball is the ball milling medium, the weight ratio of material: ball is 1:8, and the ball milling takes 5 hours. The powder after ball milling passes through a 40-mesh sieve. The sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then flat Put it into the self-propagating combustion synthesis reactor, after vacuuming, fill it with high-purity nitrogen to 2MPa, and then exhaust it. This process is repeated 3 times, then fill it with high-purity nitrogen until the pressure is kept at 4.5MPa, and use nickel-chromium with a diameter of 0.6mm The silk is used as a heating element, and a current of 25 amperes is passed through to ignite to induce the raw material p...

Embodiment 3

[0034] Embodiment 3, selects particle size and is 100 purpose metal aluminum powder (the purity of metal aluminum powder >99.5%, iron content4 Cl 15wt% and sodium azide 5wt% are mixed and put into a three-dimensional motion mixer. The inside of the mixer is lined with polyurethane and Al 2 o 3 The ball is the ball milling medium, the weight ratio of material: ball is 1:6, and the ball milling takes 3 hours. The powder after ball milling passes through a 40-mesh sieve. The sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then flat Put it into the self-propagating combustion synthesis reactor, after vacuuming, fill it with high-purity nitrogen to 2MPa, and then exhaust it. This process is repeated 3 times, and then fill it with high-purity nitrogen until the pressure is kept at 6MPa. Use a nickel-chromium wire with a diameter of 0.6mm As a heating element, a current of 25 amps is passed through to ignite and induce the raw material powder to under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com