Organic matter/mineral complex and preparation method thereof

A composite and organic technology, applied in inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve problems such as no successful reports, and achieve the effect of safe and feasible preparation process, good usability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Change the weight ratio of pig manure and sodium bentonite to prepare composites respectively.

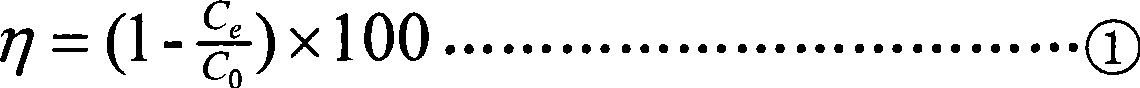

[0021] According to the preparation process of pig manure degradation liquid, the preparation process of organic-inorganic complex and the equipment used, the complex is prepared, and the pH of the system is selected to be 7, the room temperature is 25 ° C, and the stirring time is 2.5 hours. Only pig manure is changed each time. , The weight ratio of sodium-based bentonite is 1:6, 1:5, 1:4, 1:3, 1:2 or 1:1 respectively, and the organic-inorganic compound is carried out, and the obtained product has the ability to resist the heavy metal Cu 2+ The adsorption removal rate of the standard determines the weight ratio of the best pig manure and sodium bentonite. The results show that: with the weight ratio of pig manure and sodium bentonite gradually increasing, the prepared organic-inorganic composite has a greater effect on Cu 2+ The removal rate is gradually increas...

Embodiment 2

[0022] Example 2: Change the reaction time to prepare complexes respectively.

[0023] Prepare the complex according to the preparation process of the pig manure degradation solution and the preparation process of the organic-inorganic complex. Select dry pig manure: sodium bentonite = 1:3, the pH of the reaction system = 7, and the reaction temperature is 25 ° C. Change the reaction time respectively For 0.5, 1, 1.5, 2, 2.5 or 3h, organic-inorganic composite is carried out, and the obtained product is resistant to heavy metal Cu 2+ The adsorption and removal rate of the standard determines the optimal reaction time; the results show that: with the increase of the organic-inorganic composite reaction time, the prepared organic-inorganic composite is resistant to the heavy metal Cu 2+ The adsorption removal rate increases gradually, and after 2.5 hours of reaction, the removal rate tends to be balanced, and the removal rate reaches 96.41%, that is, the reaction time of 2.5 hour...

Embodiment 3

[0024] Example 3: Change the pH of the reaction system to prepare complexes respectively.

[0025] Prepare the complex according to the preparation process of pig manure degradation solution and the preparation process of organic-inorganic complex. At room temperature 25 ° C, stirring time is 2.5h, pig manure: sodium bentonite = 1: 3, use sodium hydroxide and hydrochloric acid respectively Adjust the pH of the system to 3, 5, 7, 9 or 11, and carry out organic-inorganic compounding respectively, and the obtained product is resistant to heavy metal Cu 2+ The adsorption and removal rate was determined by the standard to determine the pH value of the optimal composite system. The results showed that: when the system was neutral or slightly alkaline, the prepared organic-inorganic composite 2+ The removal rate of montmorillonite is the highest, because the surface of montmorillonite is positively charged in acidic aqueous medium, which has a repelling effect on the cations with lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com