System for producing copper oxide by circuit board sulfuric acid hydrogen peroxide microetching waste solution, and production method thereof

A technology of sulfuric acid hydrogen peroxide and circuit boards, which is applied in chemical instruments and methods, copper oxide/copper hydroxide, water/sewage multi-stage treatment, etc. The effect of low cost and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

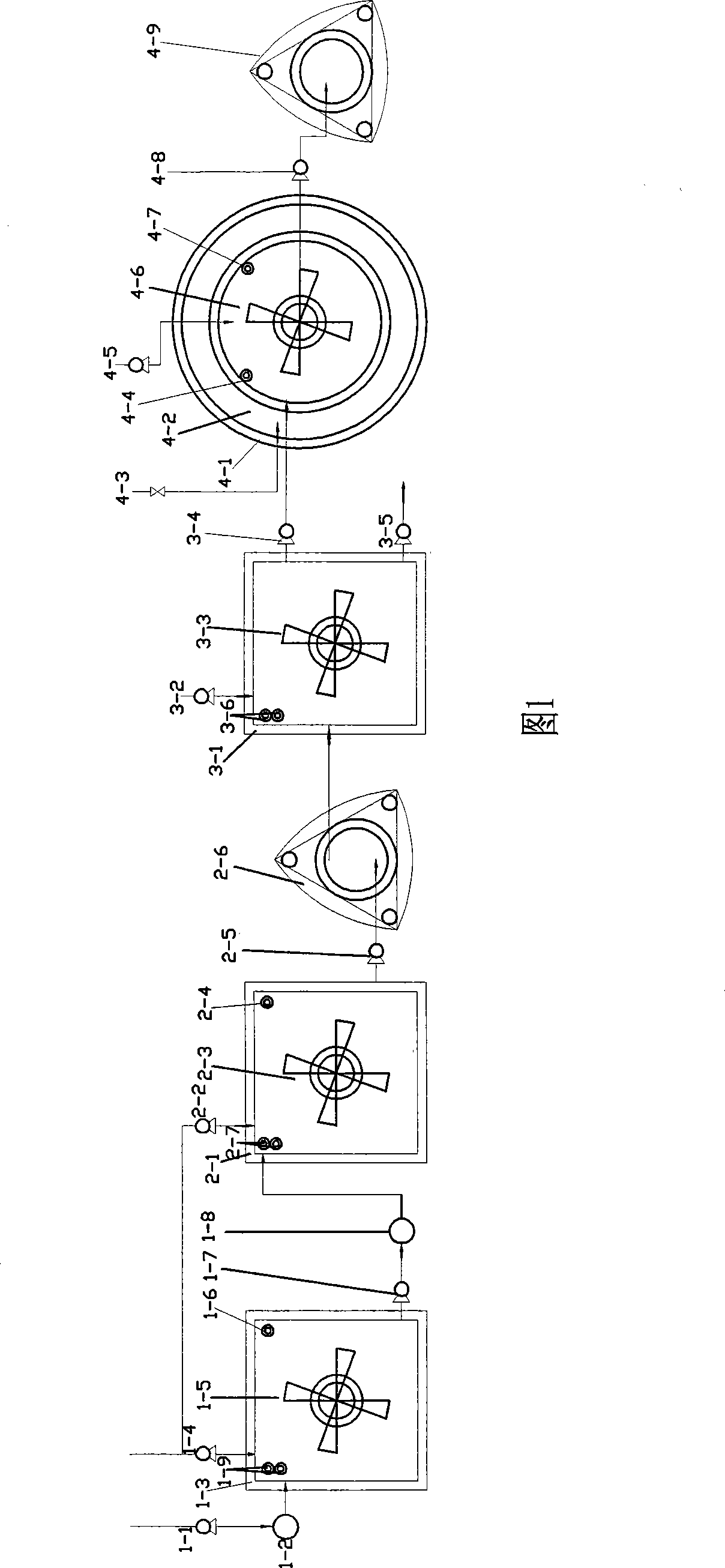

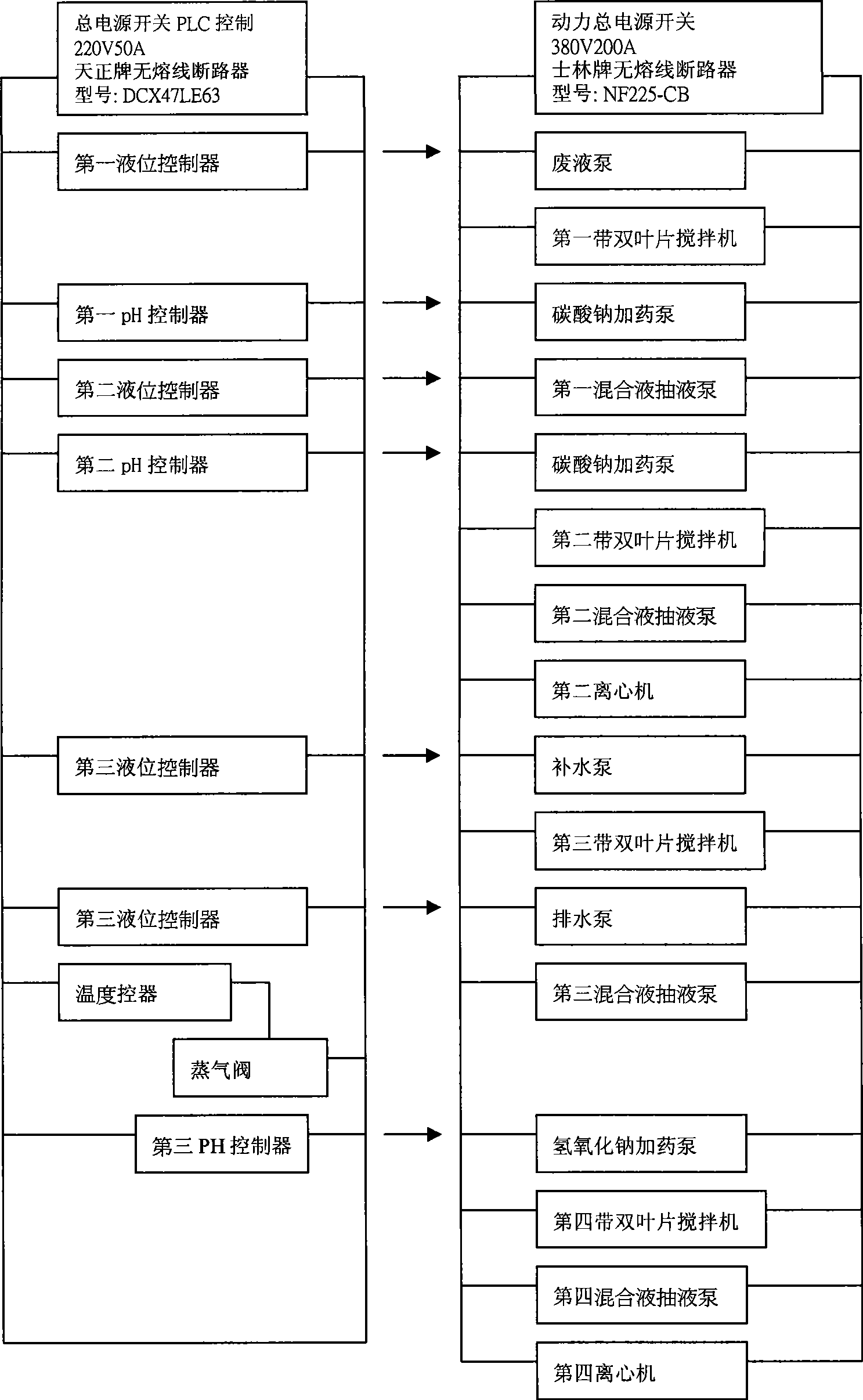

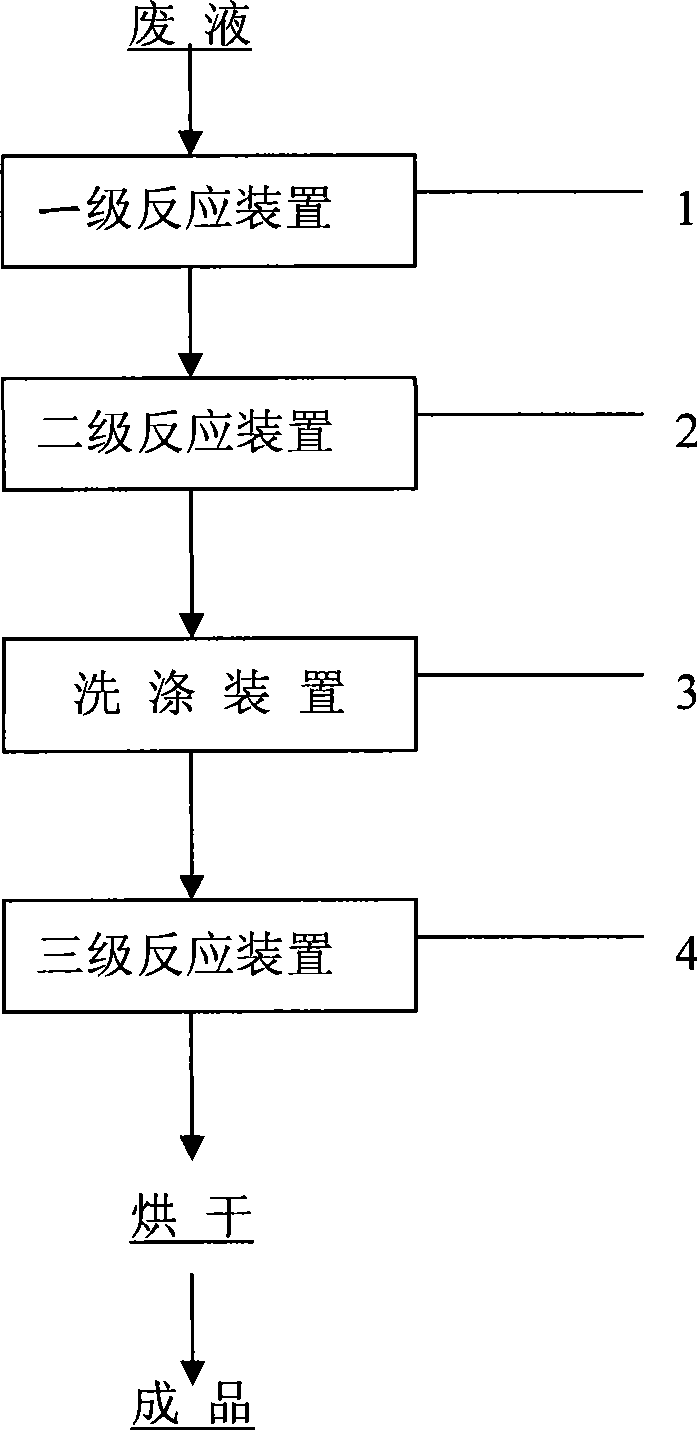

[0026] Embodiment 1: The production method of producing copper oxide from the sulfuric acid hydrogen peroxide micro-etching waste liquid of the circuit board of the present invention adopts the following process steps:

[0027] 1. First order reaction

[0028] Turn on the waste liquid pump 1-1 of the micro-etching waste liquid, and 400L of the circuit board sulfuric acid hydrogen peroxide system micro-etching waste liquid with a copper mass concentration of 35g / 1 is filtered through the cotton core filter cartridge 1-2, and then enters the primary reaction device. In the primary reactor 1-3, it is stirred by the first double-bladed mixer 1-5, and a saturated sodium carbonate solution is added at the same time. The concentration of the saturated sodium carbonate solution is 200g / l, and the pH value is adjusted to 3.5. The sulfuric acid hydrogen peroxide system is micro-etched Waste liquid and sodium carbonate saturated solution, the volume ratio between them is 1:1.5, stir for ...

Embodiment 2

[0045] Embodiment 2: The production method for producing copper oxide by recovering the micro-etching waste liquid of sulfuric acid hydrogen peroxide system of the circuit board of the present invention adopts the following process steps:

[0046] 1. Turn on the waste liquid pump 1-1 of the micro-etch waste liquid, and filter 400L of the circuit board sulfuric acid hydrogen peroxide micro-etch waste liquid with a copper mass concentration of 60g / l, filter it through the cotton core filter cartridge 1-2, and enter the primary reaction device In the primary reactor 1-3, the first double-blade mixer 1-5 is used to stir, and at the same time, a saturated solution of sodium carbonate is added. The concentration of the saturated solution of sodium carbonate is 200g / 1, and the pH value is adjusted to 4. The sulfuric acid hydrogen peroxide system is slightly Erosion waste liquid and sodium carbonate saturated solution, the volume ratio between them is 1:1.75, stir for 30 minutes, the s...

Embodiment 3

[0050] Embodiment 3: The production method for producing copper oxide by recovering the micro-etching waste liquid of sulfuric acid hydrogen peroxide system of the circuit board of the present invention adopts the following process steps:

[0051] 1. Turn on the waste liquid pump 1-1 of the micro-etch waste liquid, and filter 400L of the circuit board sulfuric acid hydrogen peroxide micro-etch waste liquid with a copper mass concentration of 10g / l, filter it through the cotton core filter cartridge 1-2, and enter the primary reaction device In the first-stage reactor 1-3, it is stirred by the first double-blade mixer 1-5, and a saturated solution of sodium carbonate is added at the same time. The concentration of the saturated solution of sodium carbonate is 200g / l, and the pH value is adjusted to 3. Erosion waste liquid and sodium carbonate saturated solution, the volume ratio between them is 1:1.25, stir for 10 minutes, the stirring speed is: 120 minutes / rotation; Waste liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com