Novel nano-composite electrochromic material, device and preparation method thereof

An electrochromic material and nanocomposite technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of poor optical activity, slow color conversion, and poor cycle reversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

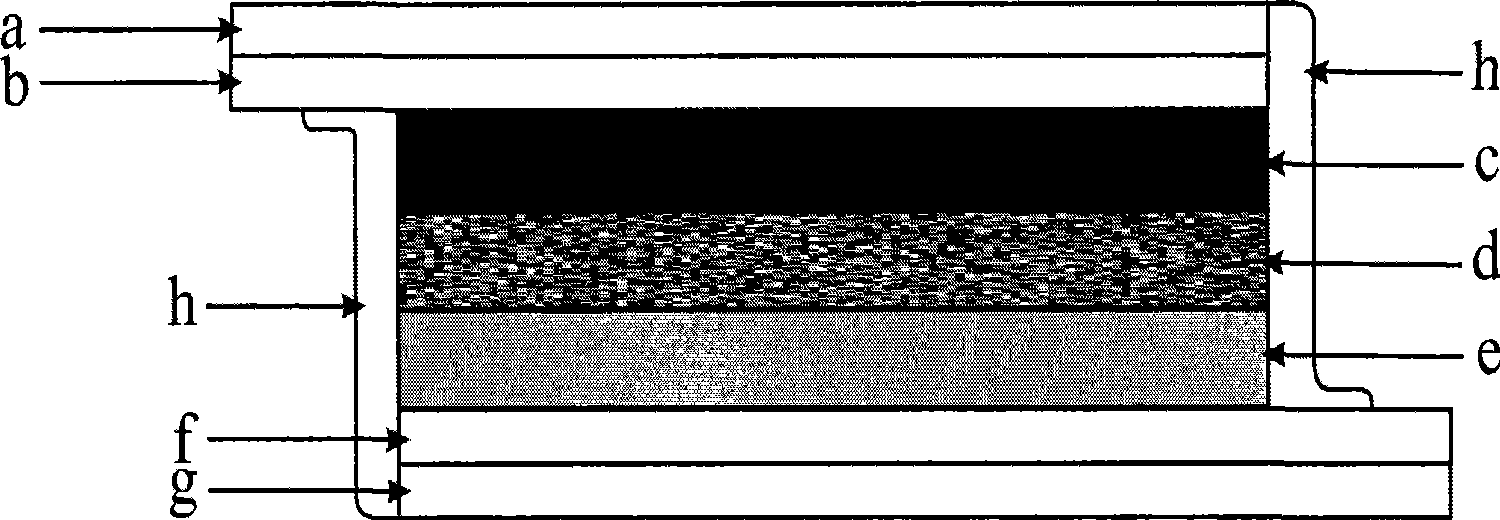

[0110] The preparation method of the device is described in detail below:

[0111] The electrochromic device is made by a method comprising the following steps:

[0112] (1) Covering the conductive electrode layer (b) and the electrochromic layer (c) sequentially on the transparent glass substrate layer (a); the electrochromic layer (c) is the nanocomposite electrochromic material of the present invention;

[0113] (2) Covering the conductive electrode layer (f) and the optional ion storage layer (e) sequentially on the transparent glass substrate layer (g);

[0114] (3) coating the ion-conducting layer (d) on the substrate obtained in step (1), then covering the substrate obtained in step (2), and then applying pressure to flatten and press;

[0115] (4) Finally, encapsulate and protect the conductive layer and the conductive glass layer with an insulating packaging material (h) to obtain the desired electrochromic device.

[0116] In a specific embodiment, the preparation ...

Embodiment 1

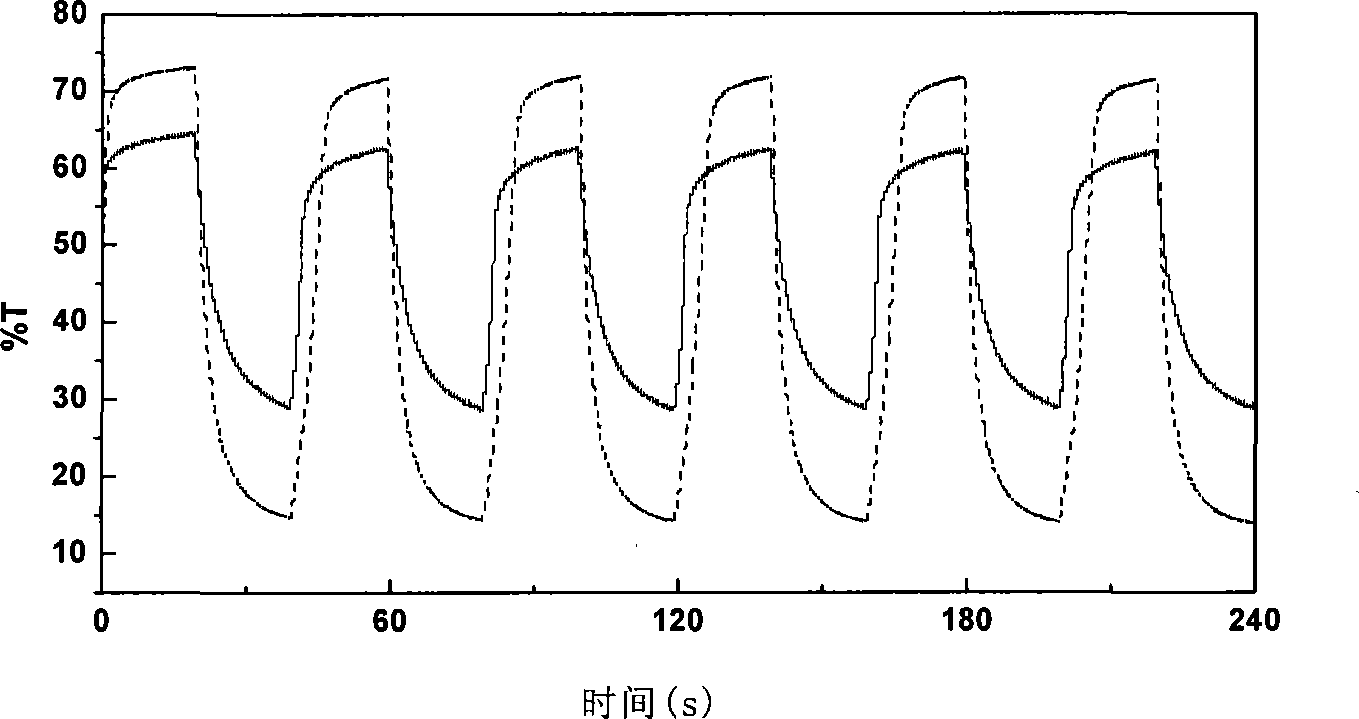

[0150] Nano Ag / WO 3 Composite electrochromic film ( nanocomposite electrochromic material )

[0151] Nano Ag / WO 3 Preparation of composite film: ITO conductive glass (5 × 1cm 2 ) with Al 2 o 3 The powder (0.05 μm) was ground and polished on suede, ultrasonicated in acetone, ethanol and water for 5 minutes, and dried in a vacuum oven.

[0152] The ITO conductive glass (5×1cm 2 ) is fixed on the bracket in the high-vacuum multi-electrode coating machine. Under the pre-vacuum degree, the residual gas in the bell jar is removed, and then it is pumped to a high vacuum degree, and then the current is passed through, and the Ag is directly heated by resistance heating. Evaporation can uniformly deposit a layer of orange nano-Ag film on the ITO conductive glass.

[0153] The nano-Ag film is orange-yellow when observed with the naked eye; measured by ultraviolet spectrophotometry, the nano-Ag film absorbs light with a wavelength of 460nm; measured by quartz film thickness me...

Embodiment 2

[0158] Glass / ITO / Nano Ag-WO 3 Electrochromic devices based on composite membrane / polymer electrolyte / ITO / glass

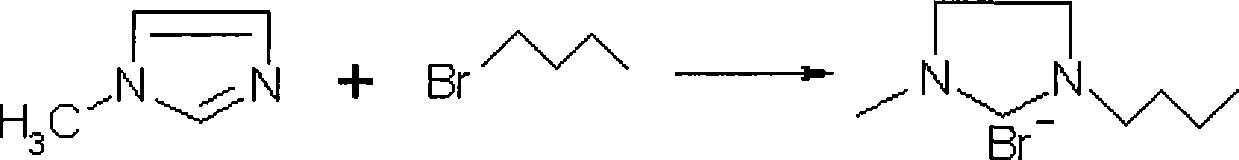

[0159] Lithium perchlorate was vacuum-dried at 150°C for 12 h to obtain anhydrous lithium perchlorate (LiClO 4 ), the anhydrous lithium perchlorate that takes 0.17g is dissolved in the acetonitrile (ACN) of 4g, then adds polymethyl methacrylate (PMMA) 0.4g, oil bath heating and vigorous stirring make PMMA dissolve completely, Add propylene carbonate (PC) 1.14g as plasticizer at last, stir to obtain colorless and transparent PMMA-LiClO 4 - PC polymer solid electrolyte.

[0160] With the nano Ag / WO prepared in embodiment 1 3 The ITO conductive glass of the composite film is used as the electrochromic layer, the conductive layer and the transparent glass substrate, and the colorless and transparent PMMA-LiClO 4 -PC polymer solid electrolyte is coated on the composite film, covered with another conductive layer and a transparent glass substrate, and then applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com