Anti-tartar detersive for quenching oil column of ethylene unit

A technology for ethylene plant and quenching oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, and the corrosion/fouling inhibition of treatment equipment. The effect of generating, inhibiting aggregation, and avoiding abnormal parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

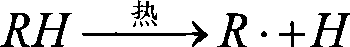

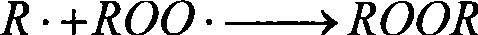

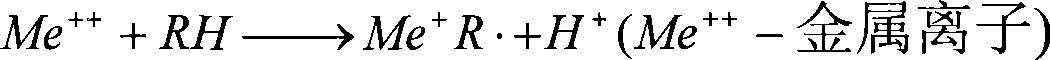

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Add 100g of 2,6 di-tert-butyl-p-cresol, 200g of triphenyl phosphite, 220g of N-ethyl-N-hydroxyethylaniline, 60g of dienyl succinimide, and 420g of kerosene into the container, and heat After stirring and mixing evenly, cool and filter to obtain the anti-scaling detergent, code-named HK-2.

[0048] The anti-scaling detergent code-named HK-2 was evaluated for its anti-scaling effect and cleaning effect.

[0049] laboratory evaluation

[0050] (1) Anti-scaling effect evaluation method of HK-2 anti-scaling detergent:

[0051] The evaluation method of anti-scaling effect of anti-scaling agent is based on the principle of heat transfer. It uses a heat pipe to allow the medium to flow continuously in the heat pipe. At the beginning, because the medium has not scaled on the heat pipe, the total heat transfer resistance is only the heat transfer resistance of the heat pipe wall; as the running time increases, Scale is continuously deposited on the surface of the heat pipe, for...

Embodiment 2

[0069] 170g 2-tert-butyl-4,6-dimethylphenol, 150g triisooctyl phosphite, 210g 2,4-dimethylaniline, 50g polyenyl succinimide, 420g toluene, other same implementation example 1.

Embodiment 3

[0070] Example 3 N-Methyl-N-benzylaniline.

[0071] 150g 2,6-di-tert-butyl-4-n-butylphenol, 120g triphenyl phosphate, 240g N-methyl-N-benzylaniline, 80g low nitrogen polyisobutylene succinimide, 410g toluene, others With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com