Y2O3-Lu2O3 system composite rare earth-molybdenum electron emission material and preparation method thereof

An electron emission material, y2o3-lu2o3 technology, is applied in the direction of secondary electron emission electrodes, light-emitting cathode manufacturing, discharge tube main electrode, etc., which can solve the problems of difficult cathode vibration, inconvenient processing, high activation temperature, etc., and achieve improved material The effect of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

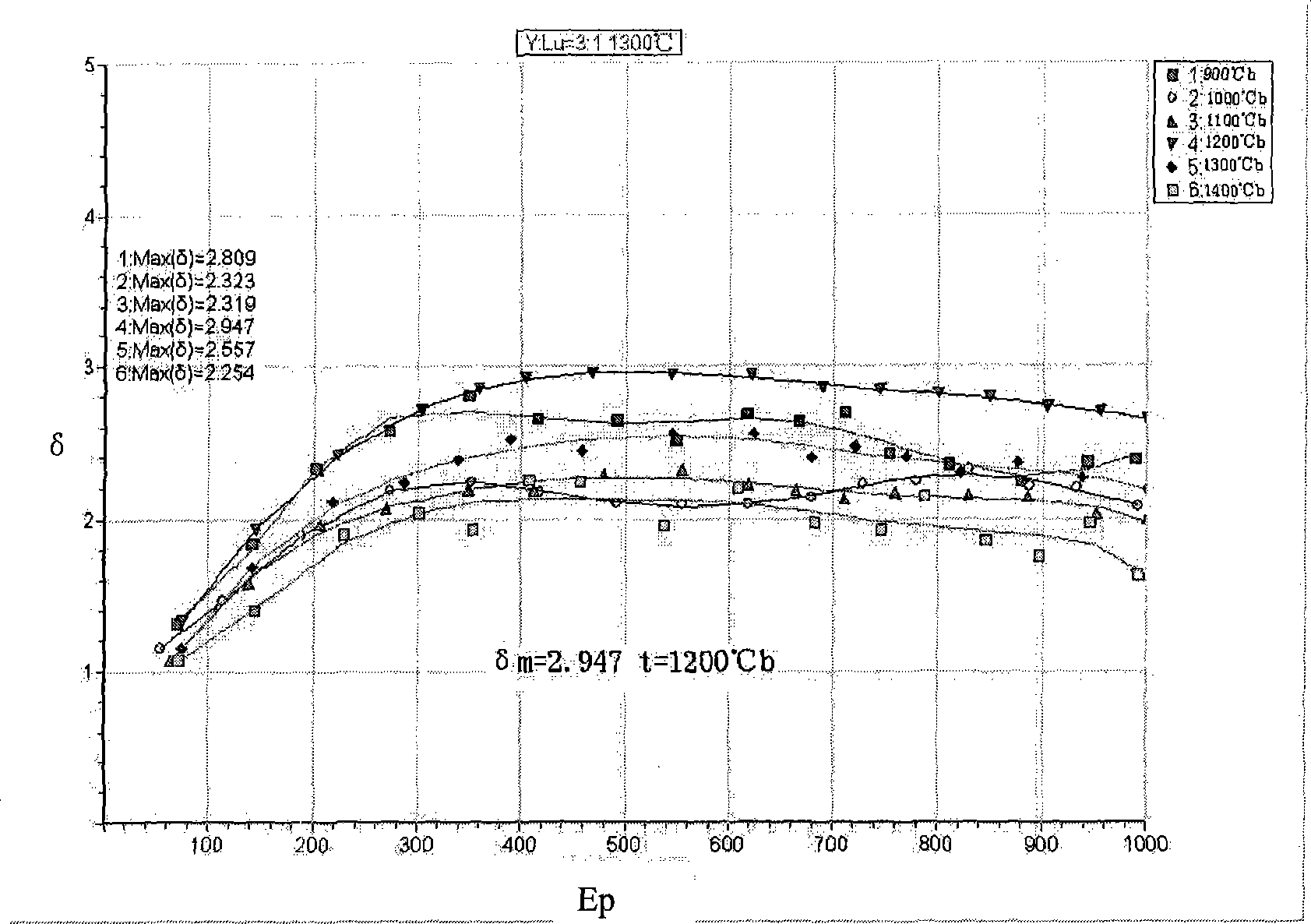

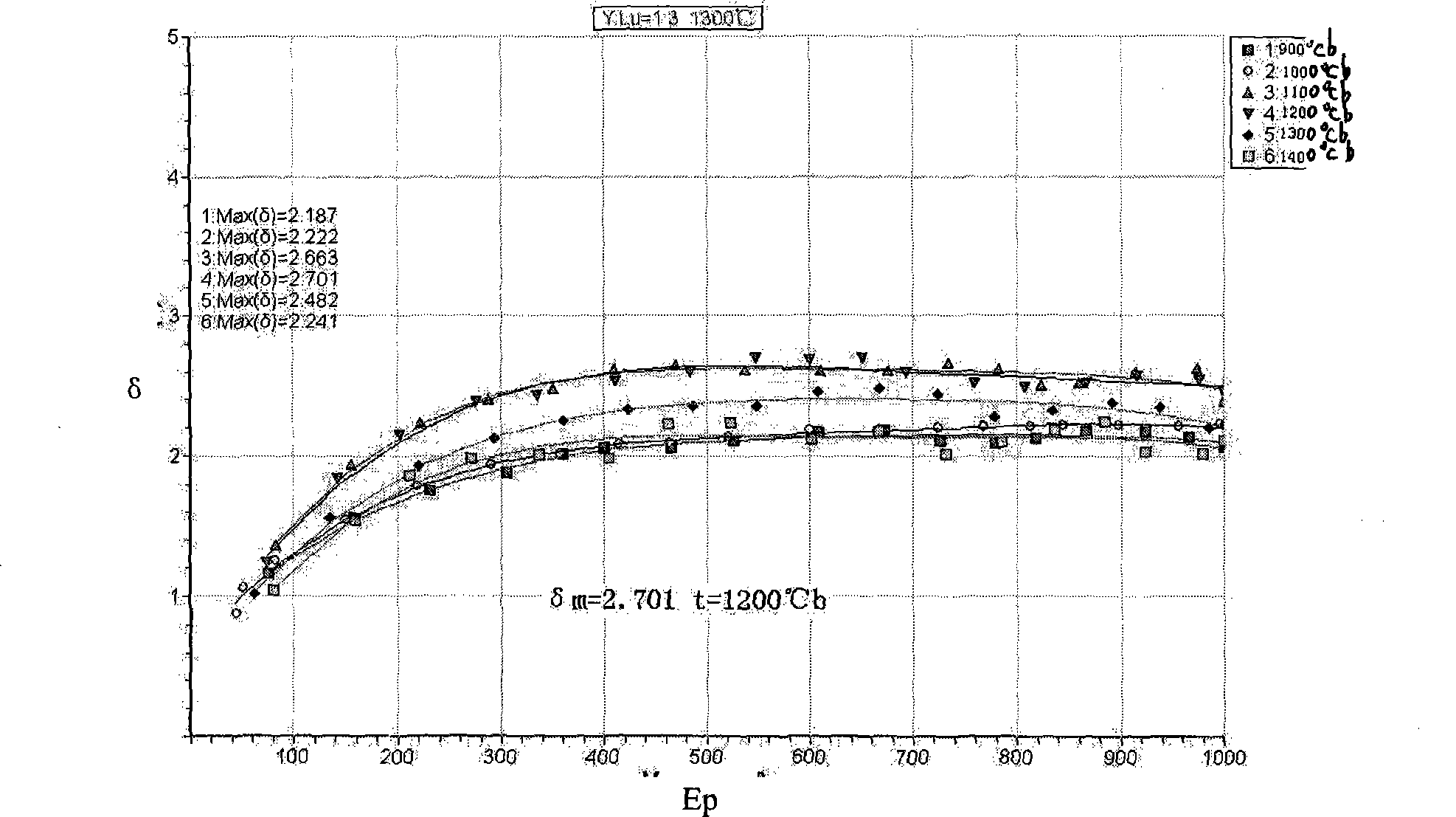

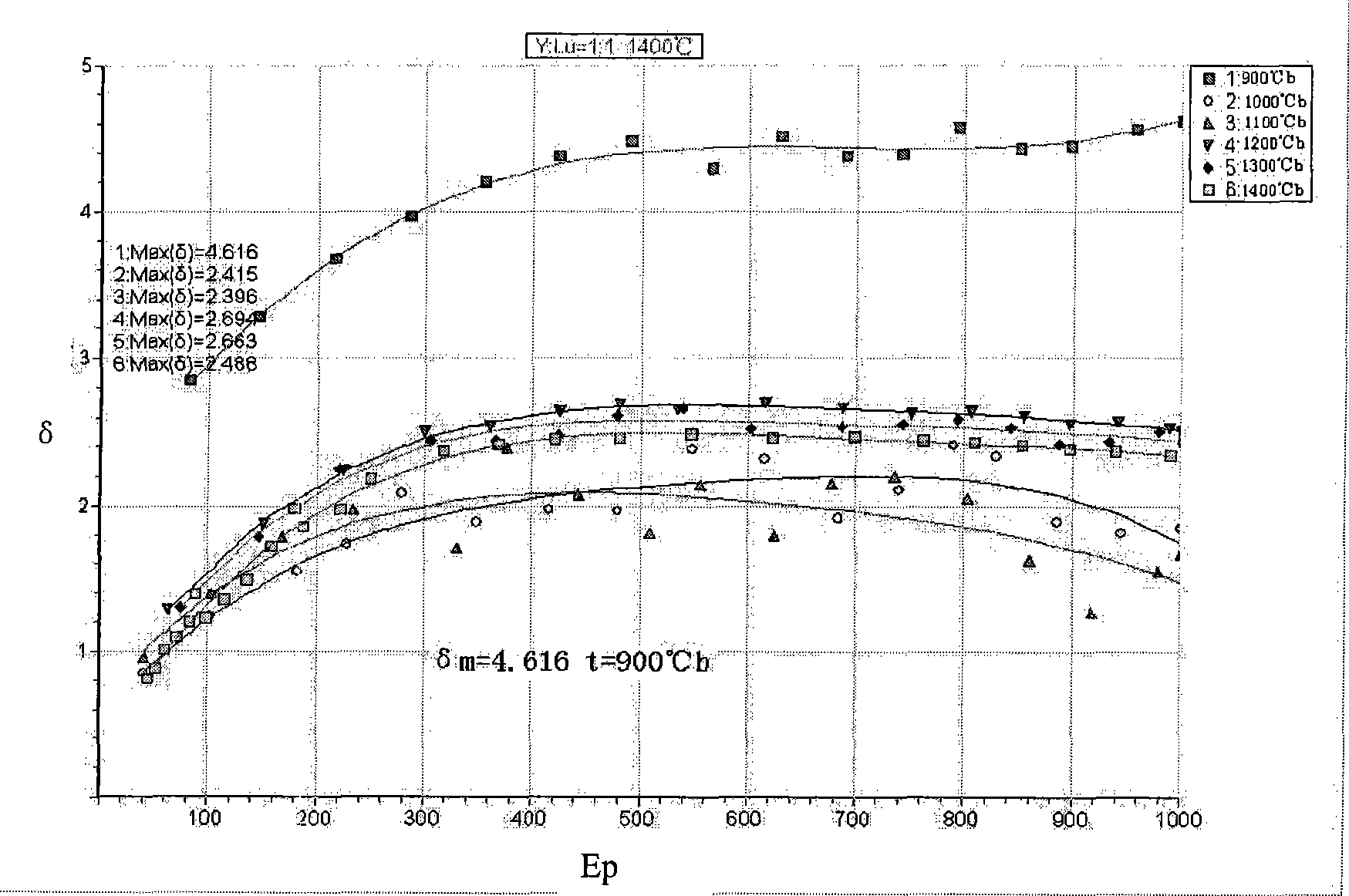

Image

Examples

Embodiment 1

[0022] (1) Dissolve 48.4934 grams of yttrium nitrate and 10.4301 grams of lutetium nitrate in absolute ethanol respectively, filter the solution after completely dissolving, weigh 120.0235 grams of molybdenum trioxide powder and mix it with the filtered nitrate solution, and place them in a water bath at 80°C Heat over medium heat, stirring constantly, until the liquid evaporates completely.

[0023] (2) Decompose the powder obtained after evaporation at 500° C. under an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0024] (3) Crushing and sieving the powder, and then reducing the powder under a hydrogen atmosphere. The reduction is carried out in two steps. First, hold at 500°C for 2 hours, then raise the temperature to 900°C for 2 hours, and then cool with the furnace. The reduced powder is pressed and sintered to make a rare earth-molybdenum secondary electron emission material green body. The embryo bo...

Embodiment 2

[0026] (1) Dissolve 48.4934 grams of yttrium nitrate and 10.4301 grams of lutetium nitrate in absolute ethanol respectively, and filter the solution after completely dissolving. Weigh 120.0235 g of molybdenum trioxide powder and mix it with the filtered nitrate solution, and heat it in a water bath at 90°C, stirring continuously until the liquid evaporates completely.

[0027] (2) Decompose the powder obtained after evaporation at 550° C. under an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0028] (3) Crushing and sieving the powder, and then reducing the powder under a hydrogen atmosphere. The reduction is carried out in two steps. First, hold at 550°C for 4 hours, then increase the temperature to 950°C for 4 hours, and then cool with the furnace. The reduced powder is pressed and sintered to make a rare earth-molybdenum secondary electron emission material green body. The embryo body is machined into a...

Embodiment 3

[0030] (1) Dissolve 32.3289 grams of yttrium nitrate and 20.8602 grams of lutetium nitrate in absolute ethanol respectively, and filter the solution after completely dissolving. Weigh 120.0235 g of molybdenum trioxide powder and mix it with the filtered nitrate solution, and heat it in a water bath at 100°C, stirring continuously until the liquid evaporates completely.

[0031] (2) Decompose the powder obtained after evaporation at 520° C. under an air atmosphere until the nitrate is completely decomposed, and the N element in the powder is completely removed.

[0032](3) Crushing and sieving the powder, and then reducing the powder under a hydrogen atmosphere. The reduction is carried out in two steps. First, hold at 520°C for 3 hours, then increase the temperature to 920°C for 3 hours, and then cool with the furnace. The reduced powder is pressed and sintered to make a rare earth-molybdenum secondary electron emission material green body. The embryo body is machined into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com