Selective hydrogenation method of acetylene hydrocarbon and dialkene in cracking gas

A technology for selective hydrogenation and diolefins, applied in the field of selective hydrogenation of alkynes and diolefins, which can solve the problems of limited hydrogen, increased energy consumption, and reduced activity of polymerization catalysts, so as to reduce energy consumption and equipment size, and improve selection Safety and safety, and the effect of reducing the number of reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

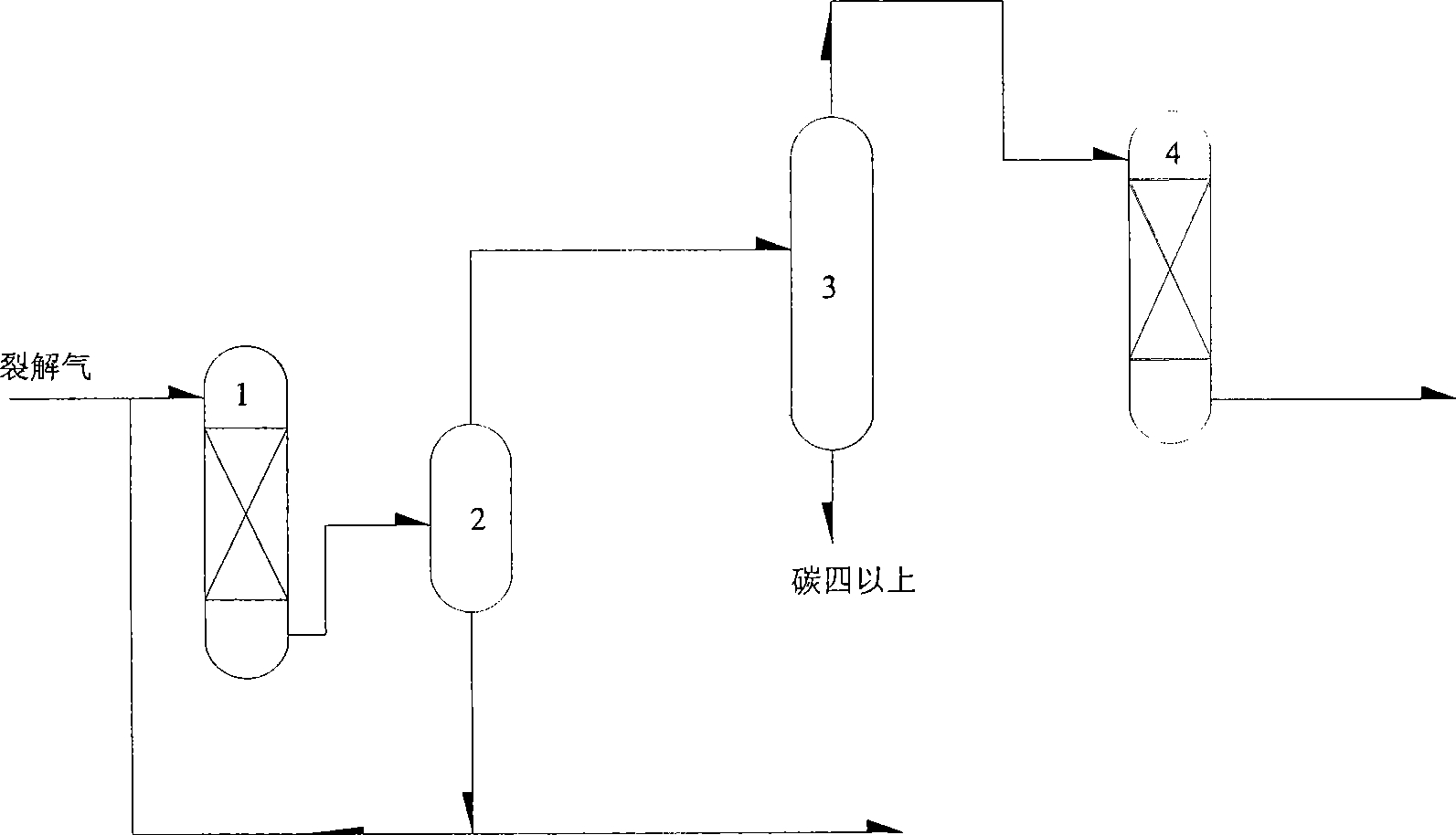

[0054] As a more specific embodiment of the present invention, comprising the following steps:

[0055] a. Cool the feedstock containing olefins to 10°C to 90°C through a heat exchanger;

[0056] b. Sending the material from step a into the mixed-phase hydrogenation reactor 1, at least partially hydrogenating the highly unsaturated hydrocarbons therein;

[0057] c. the effluent from the mixed-phase hydrogenation reactor 1 is cooled by a cooler, and the cooled stream is sent to the condensing fractionator 2, and is separated into an uncondensed stream and a condensed stream comprising carbon six and heavier components, and A part of the condensate stream rich in C6 and heavier components is sent to the mixed-phase hydrogenation reactor 1, and the remaining part is withdrawn;

[0058] d. Include the C 5 And the stream of lighter components is sent to the front depropanizer 3, separated into C-rich 3 and gas phase streams of lighter components and containing C 4 And the liqui...

Embodiment 1

[0062] see figure 1 , the gas-phase raw material containing olefins obtained from the steam cracking unit is mixed with the condensate stream from the fractionator, then heat exchanged in the heat exchanger, and then enters the mixed-phase hydrogenation reactor 1. Mixed-phase hydrogenation reactor 1 uses BC-L-83A hydrogenation catalyst (Sinopec Produced by the company's Beijing Research Institute of Chemical Industry) to operate in the presence of, for example, the reaction temperature is 60 ° C, the reaction pressure is 2.0 MPa, and the volume space velocity of the gas phase raw material is 1100 h -1 , the volumetric space velocity of the liquid stream is 3h -1, the acetylene in it can be hydrogenated to 100-200ppm, the conversion rate of propyne and propadiene is 50%, and the conversion rate of dienes with carbon four or more is more than 80%. The reaction product from the mixed-phase hydrogenation reactor is cooled by a cooler and enters the condensing fractionator 2, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com