Electric tuning optical attenuator

A technology of optical attenuator and electrical tuning, which is applied in the direction of optics, instruments, optical components, etc., to achieve the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

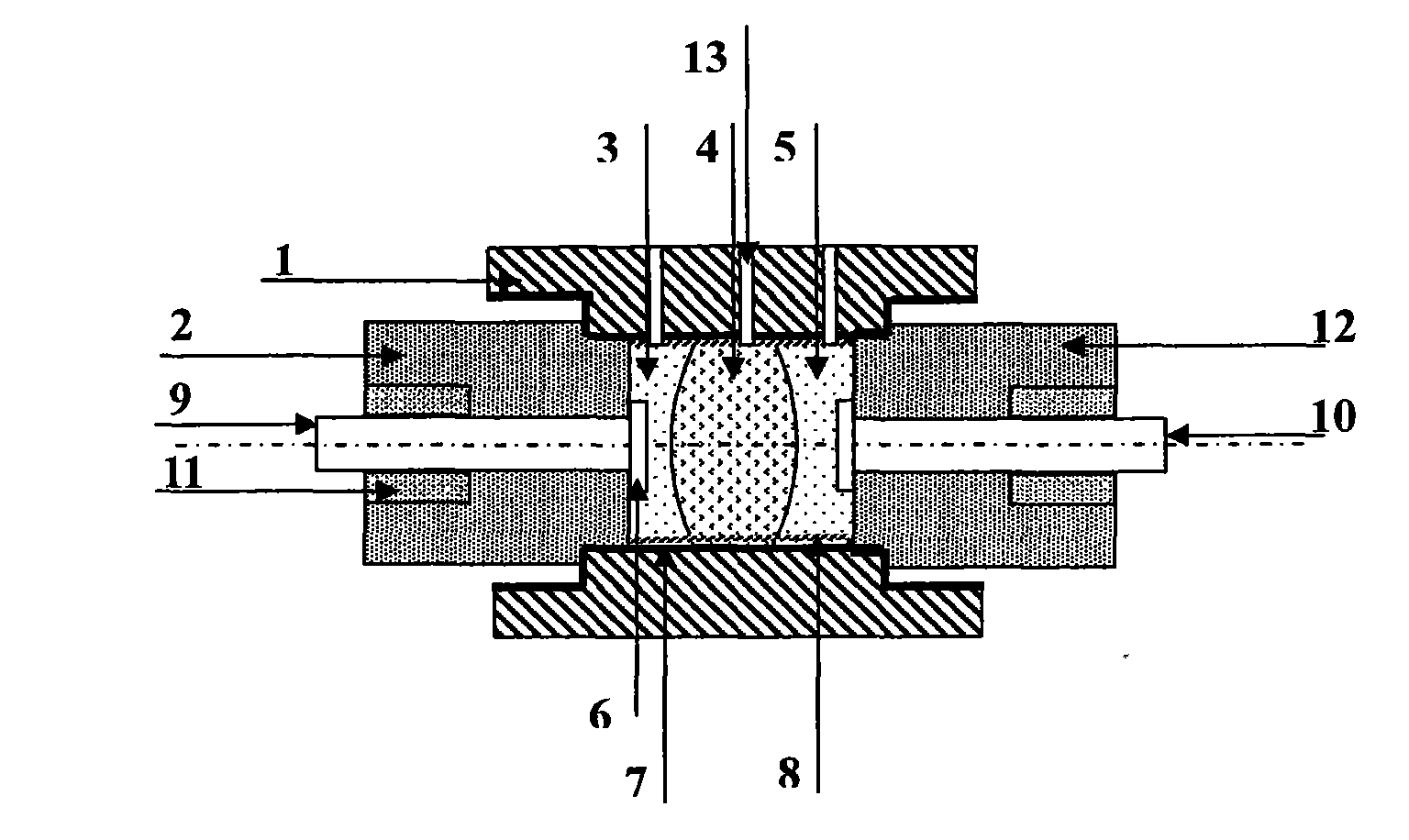

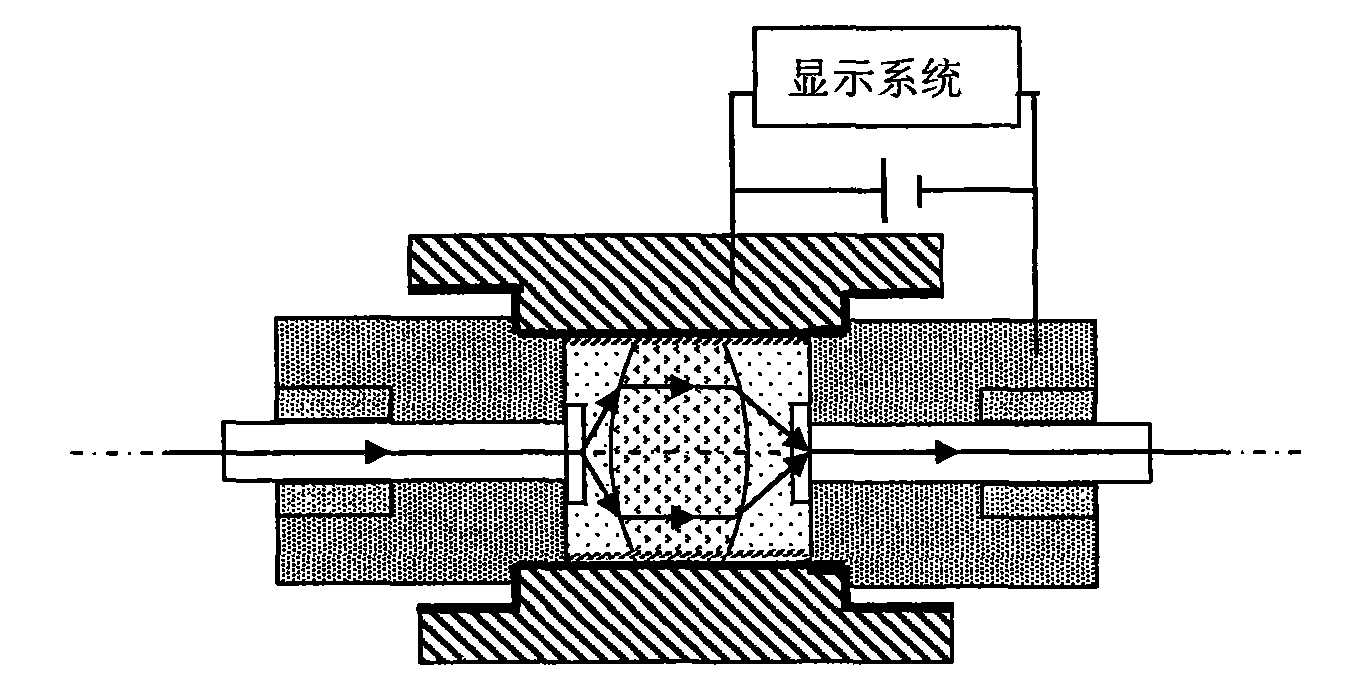

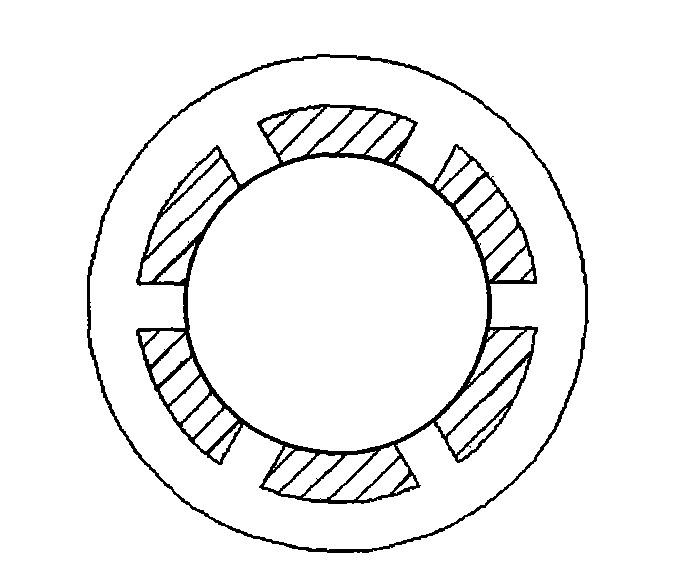

[0017] The precision casing 1 is made of conductive silicone rubber. This is because the conductive silicone rubber is easy to extrude and can be mass-produced through mold injection molding, and can be used as an electrode; three injection holes 13 are reserved on one side of the casing. The pin 2 or 12 of the other electrode connector is made of a metal copper column precision machined and polished, because metal copper is a common metal and easy to process; the size of the hole matches the outer diameter of the input optical fiber 9 and output optical fiber 10 . Conductive Fluid 3 or 5 may have freezing problems when used at low temperatures. High concentration salt solutions can be used to lower the freezing point. In order to maintain the low density and refractive index of the brine, a low atomic weight salt is used: lithium chloride. Lithium chloride at a concentration of 20% results in a freezing point below -40°C, a density ρ of 1.12kg / m3, and a refractive index of...

Embodiment 2

[0020] The precision casing is prepared by precision machining of metal copper and copper pillars into a casing and polished. Three small holes are reserved on the wall of the copper casing for fluid injection. The connector pins are made of conductive silicone rubber, and the hollow space is reserved for the optical fiber. Due to the flexibility of the silicone rubber, the insertion and extraction of the optical fiber is more convenient. The transparent substrate still uses a high-performance cover glass. The insulating layer is made of parylene with a thickness of 3 microns by vacuum coating. The hydrophobic layer is made of polytetrafluoroethylene polymer material (the English abbreviation is PTFE, and the trade name is Teflon). , Teflon@AF) coating to achieve. In order to simplify the manufacturing process, the first low-refractive-index fluid can be made into a cured lens by using ultraviolet or visible light curable glue. The insulating fluid is bromododecane (densit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com