Ultra-hydrophobic film of compound structure

A composite structure, super-hydrophobic technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc. Problems such as high structural cost, to achieve the effect of easy promotion, simple structure and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

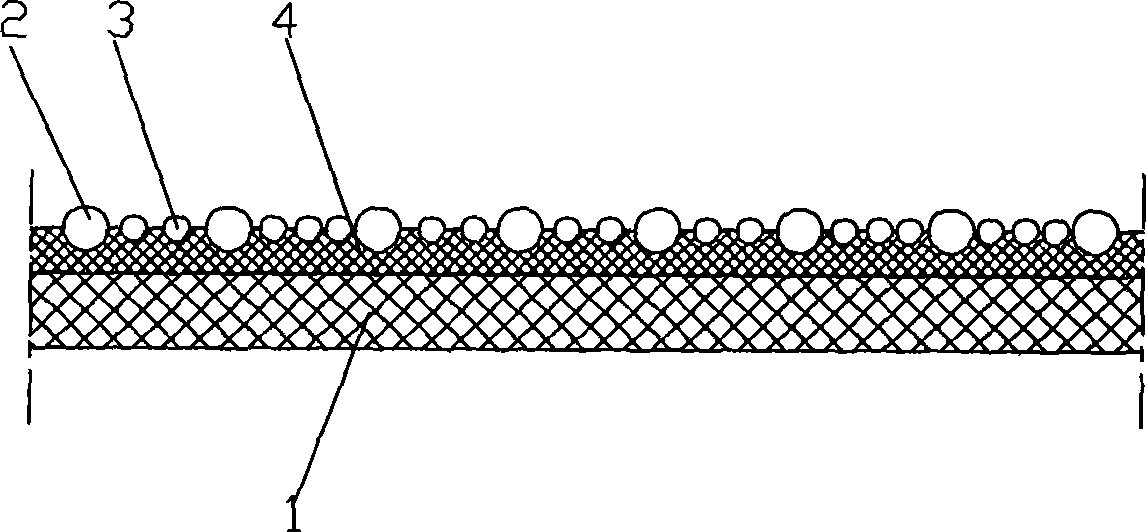

[0022] The superhydrophobic membrane of the composite structure of the present embodiment comprises a membrane substrate 1, an adhesive layer 4 and a superhydrophobic layer, the adhesive layer 4 is bonded to the membrane substrate 1, and the superhydrophobic layer is composed of micron-sized membranes arranged alternately and embedded in the adhesive layer. Composed of powder 2 and nano-scale powder 3, micron-scale powder 2 and nano-scale powder 3 form micron-scale protrusions and nano-scale protrusions on the surface of the bonding layer; in this embodiment, the material of the bonding layer is vinyl fluoride -Vinyl ether polymer, with good viscosity and strong adaptability, can be applied to various surfaces; micron-sized powder particles 2 and nano-sized powder particles 3 have low surface energy; in this embodiment, micron-sized powder particles with low surface energy Powder 2 and nanoscale powder 3 are polytetrafluoroethylene micropowders;

[0023] The particle size of t...

Embodiment 2

[0026] The superhydrophobic membrane of the composite structure of the present embodiment comprises a membrane substrate 1, an adhesive layer 4 and a superhydrophobic layer, the adhesive layer 4 is bonded to the membrane substrate 1, and the superhydrophobic layer is composed of micron-sized membranes arranged alternately and embedded in the adhesive layer. Composed of powder 2 and nanoscale powder 3, micron-scale powder 2 and nanoscale powder 3 form micron-scale protrusions and nano-scale protrusions on the surface of the bonding layer; in this embodiment, the material of the bonding layer is fluorine-containing Acrylic ester has stable physical properties and strong adaptability, and can be applied to various surfaces; micron-sized particles 2 and nano-sized particles 3 are modified with low surface energy substances. The micron-sized powder 2 and nano-sized powder 3 are silicon dioxide, of course, they can also be one or more mixtures of titanium dioxide, calcium carbonate a...

Embodiment 3

[0030] The superhydrophobic membrane of the composite structure of the present embodiment comprises a membrane substrate 1, an adhesive layer 4 and a superhydrophobic layer, the adhesive layer 4 is bonded to the membrane substrate 1, and the superhydrophobic layer is composed of micron-sized membranes arranged alternately and embedded in the adhesive layer. Composed of powder 2 and nano-scale powder 3, micron-scale powder 2 and nano-scale powder 3 form micron-scale protrusions and nano-scale protrusions on the surface of the bonding layer; in this embodiment, the material of the bonding layer is polyurethane resin , stable physical properties, high viscosity, strong adaptability, applicable to various surfaces; micron-sized powder 2 and nano-sized powder 3 have low surface energy; in this embodiment, micron-sized powder 2 with low surface energy and nanoscale powder 3 is perfluoroethylene propylene micropowder;

[0031] The particle size of the mixed powder of micron-scale pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com