Multiple antimonate luminescent materials for white light LED and preparation thereof

A fluorescent material, antimonate technology, applied in the field of fluorescent materials, can solve the problem of low conversion efficiency of fluorescent powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

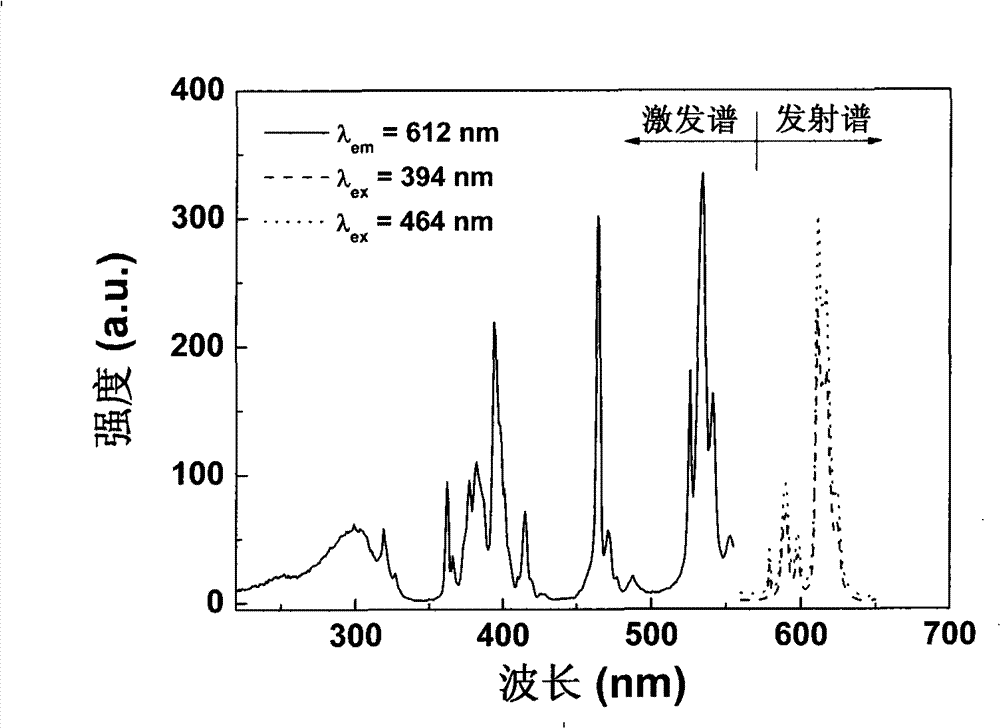

[0044] Raw material CaCO 3 、Eu 2 o 3 , Sb 2 o 3 According to Ca 2 EuSbO 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover and pre-fired at 625°C for 24h. The obtained powder is fully ground and then fired at 1000°C, 1200°C and 1400°C for 24 hours respectively. Made into pure Ca 2 EuSbO 6 fluorescent material. see test results figure 1 .

Embodiment 2

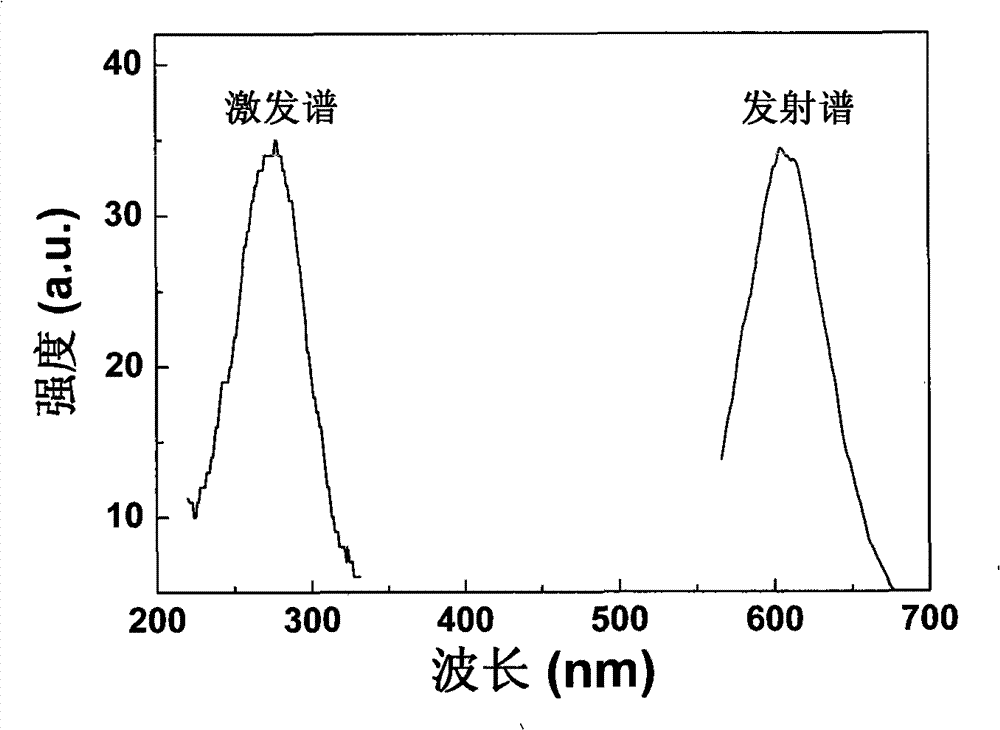

[0046] The raw material Ca(NO 3 ) 2 4H 2 O, Y 2 o 3 , Sb 2 o 3 According to Ca 2 wxya 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover and pre-fired at 625°C for 24h. The obtained powder is fully ground and then fired at 1000°C, 1200°C and 1350°C for 24 hours respectively. Made into pure Ca 2 wxya 6 . The resulting Ca 2 wxya 6 Powder and MnO by Ca 2 wxya 6 :Mn x (x=0-0.3) was ground evenly, and then placed in a vacuumized fused-sealed quartz tube at 950° C. for 24 hours for subsequent doping. get Ca 2 wxya 6 : Mn fluorescent material. see test results figure 2 .

Embodiment 3

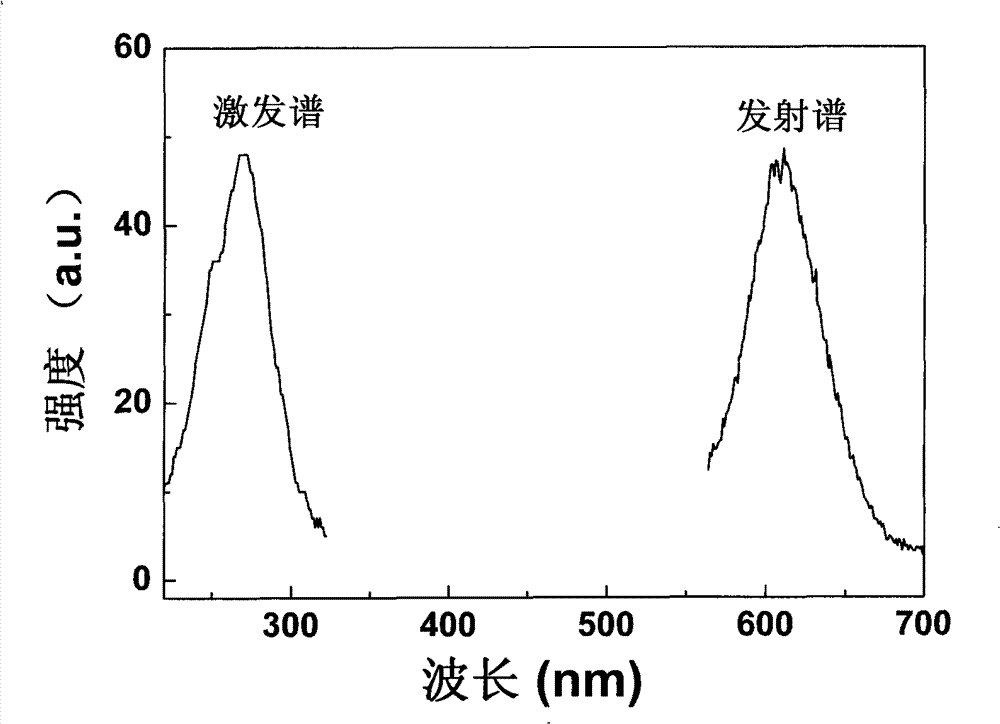

[0048] Raw material CaCO 3 , La(NO 3 ) 3 ·6H 2 O, Sb 2 o 3 According to Ca 2 CaO 6 The stoichiometric ratio was weighed, mixed evenly in a mortar, put into a corundum crucible with a cover and pre-fired at 625°C for 24h. The obtained powder is fully ground and then fired at 1000°C, 1200°C and 1350°C for 24 hours respectively. Made into pure Ca 2 CaO 6 . The resulting Ca 2 CaO 6 Powder and MnO by Ca 2 CaO 6 :Mn x (x=0-0.3) was ground evenly, and then placed in a vacuumized fused-sealed quartz tube at 950° C. for 24 hours for subsequent doping. get Ca 2 CaO 6 : Mn fluorescent material. see test results image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com