Preparation of controlled release long-acting fertilizer

A technology of long-acting fertilizers and preparation steps, which is applied in the direction of fertilizer forms, fertilization devices, fertilizer mixtures, etc., which can solve the problems of complex production processes, flammable and explosive fertilizers, and high fertilizer prices, and achieve simple production processes, less residual by-products, Effect of increased fertilizer costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

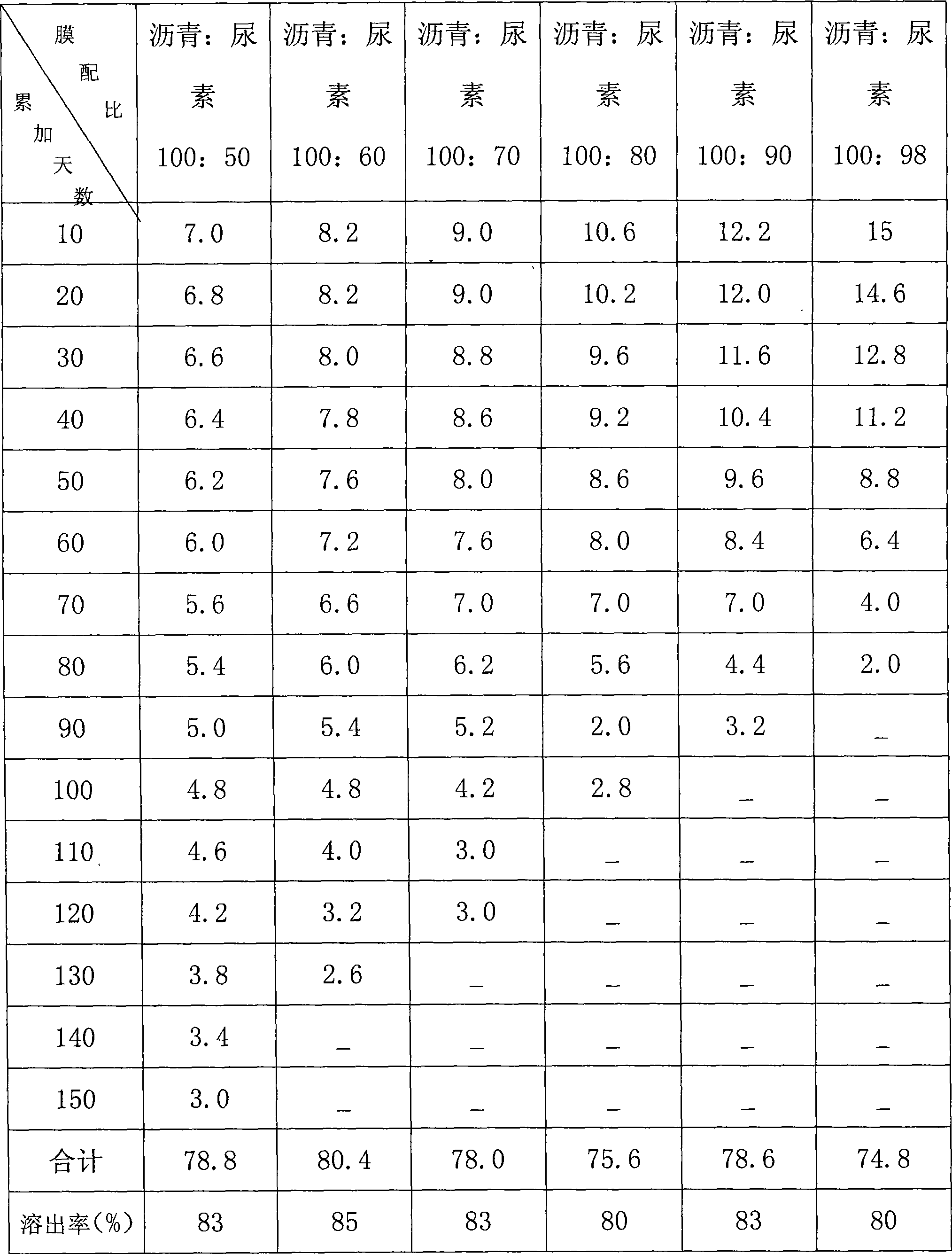

Embodiment 1

[0021] Use a roller briquette briquetting machine to briquette, the pressure is about 50Kg / cm 2 , carry out dry fertilizer briquetting treatment on the fertilizer, the shape of the block is columnar or cylindrical, and the fertilizer can be compound fertilizer, compound fertilizer or simple fertilizer. Then put the asphalt into the heating container, heat to melt the asphalt, the temperature is controlled below the ignition point of the asphalt, and the viscosity reaches the lowest point. Finally, add urea and flour to the melted asphalt and stir thoroughly, put the pressed fertilizer block into a mixture of 100 parts by weight of asphalt, 50 parts of urea and 0.5 parts of flour, then take it out with an iron basket and put it on the flour Roll and evenly stick a layer on the surface to prevent mutual adhesion before solidification. The controlled release time is 150 days, the dissolution rate is 83%, and the coating rate is 5%.

Embodiment 2

[0023] Granulate with a rolling granulator, the pressure is about 50Kg / cm 2 , all the other are the same as Example 1, wherein 100 parts of asphalt, 60 parts of urea, 2.5 parts of flour, controlled release time 130 days, dissolution rate 85%, coating rate 5.5%.

Embodiment 3

[0025] The rest are the same as in Example 1, wherein 100 parts of asphalt, 70 parts of urea, 4.5 parts of flour, 120 days of controlled release time, 83% of stripping rate, and 5% of coating rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com