Preparation of calcium zinc composite stabilizer for processing plastic

A composite stabilizer and stabilizer technology, applied in the field of plastic additives, can solve the problems of inconvenient use and high cost, and achieve the effects of high thermal efficiency, low cost and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

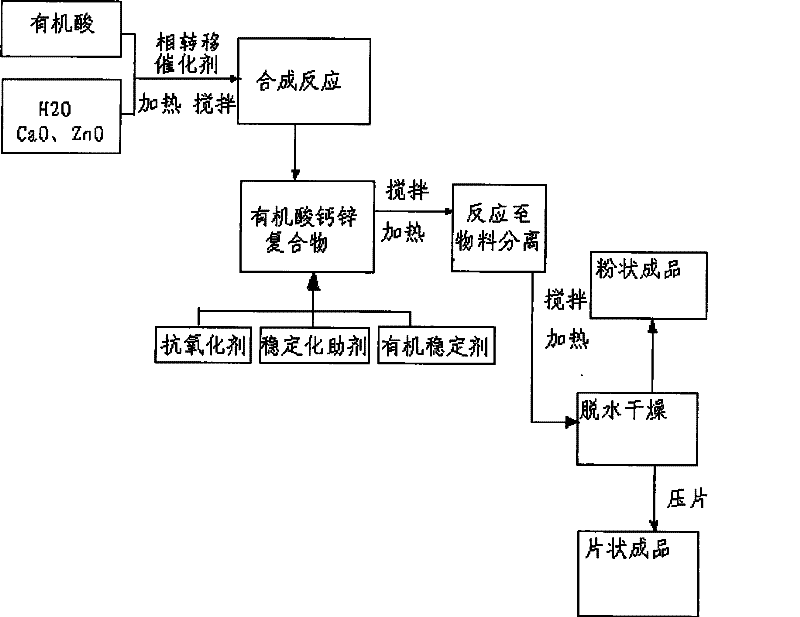

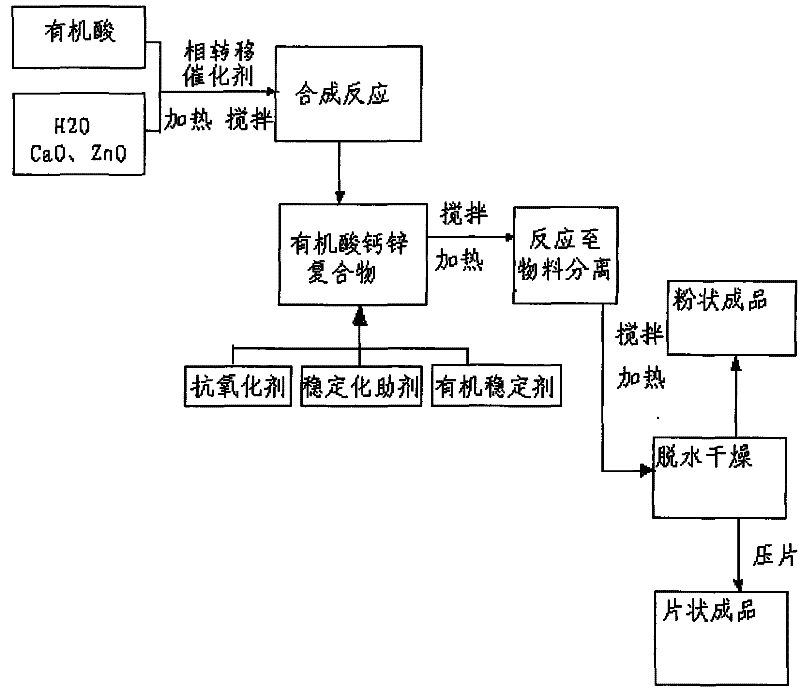

[0024] figure 1 Be the flow chart of reaction technique of the present invention, below will refer to figure 1 The preparation method of the present invention for producing the calcium-zinc composite stabilizer for PVC plastic processing is described in detail.

[0025] Synthetic calcium-zinc composite stabilizer: weigh salicylic acid 138kg, calcium oxide powder 32kg (particle size 200 mesh) and zinc oxide powder 8kg (particle size 200 mesh) and disperse in distilled water, weigh phase transfer catalyst diethylene glycol (industrial grade) 2kg, the reaction temperature is 80-90°C, the reaction time is 4.5-5h, and the organic acid calcium-zinc complex is formed in one step.

[0026] Coating and dehydration: When the organic acid calcium-zinc complex synthesized above is heated to 70-80°C, add epoxidized soybean oil and paraffin, and stir for 1 hour until the material and water are separated (the layers are clear).

[0027] Devolatilization and drying: put the coated and dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com