Ionic compound

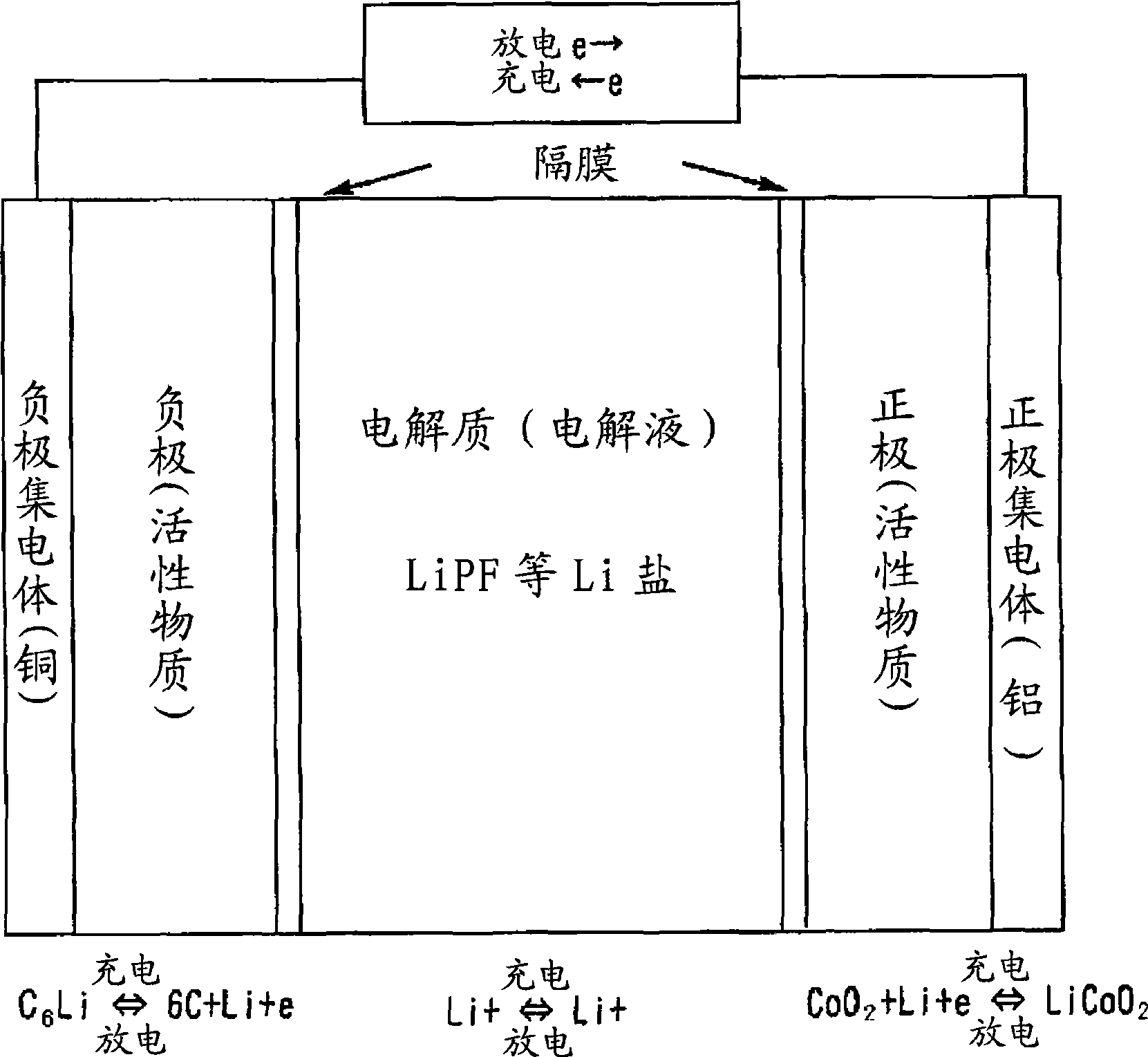

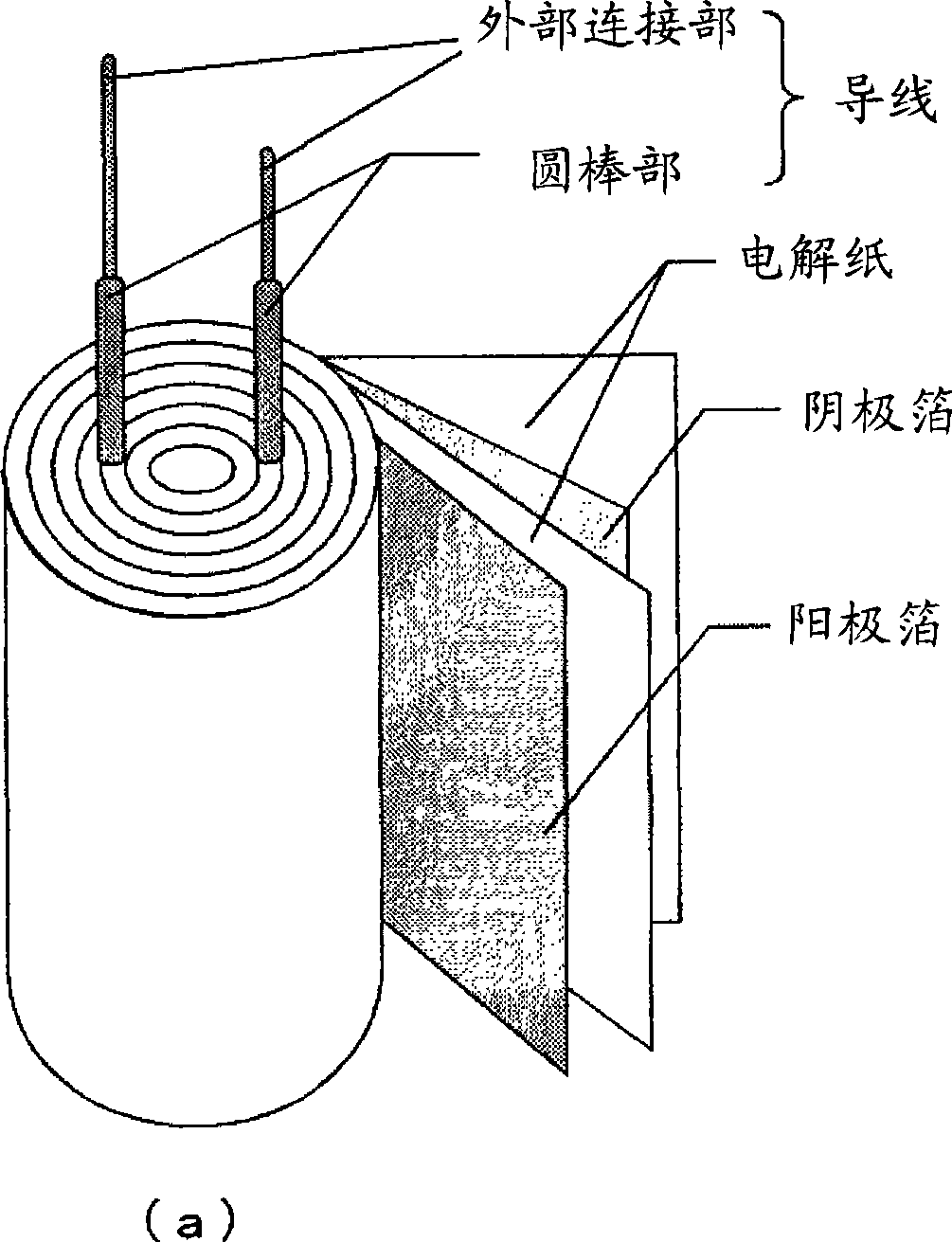

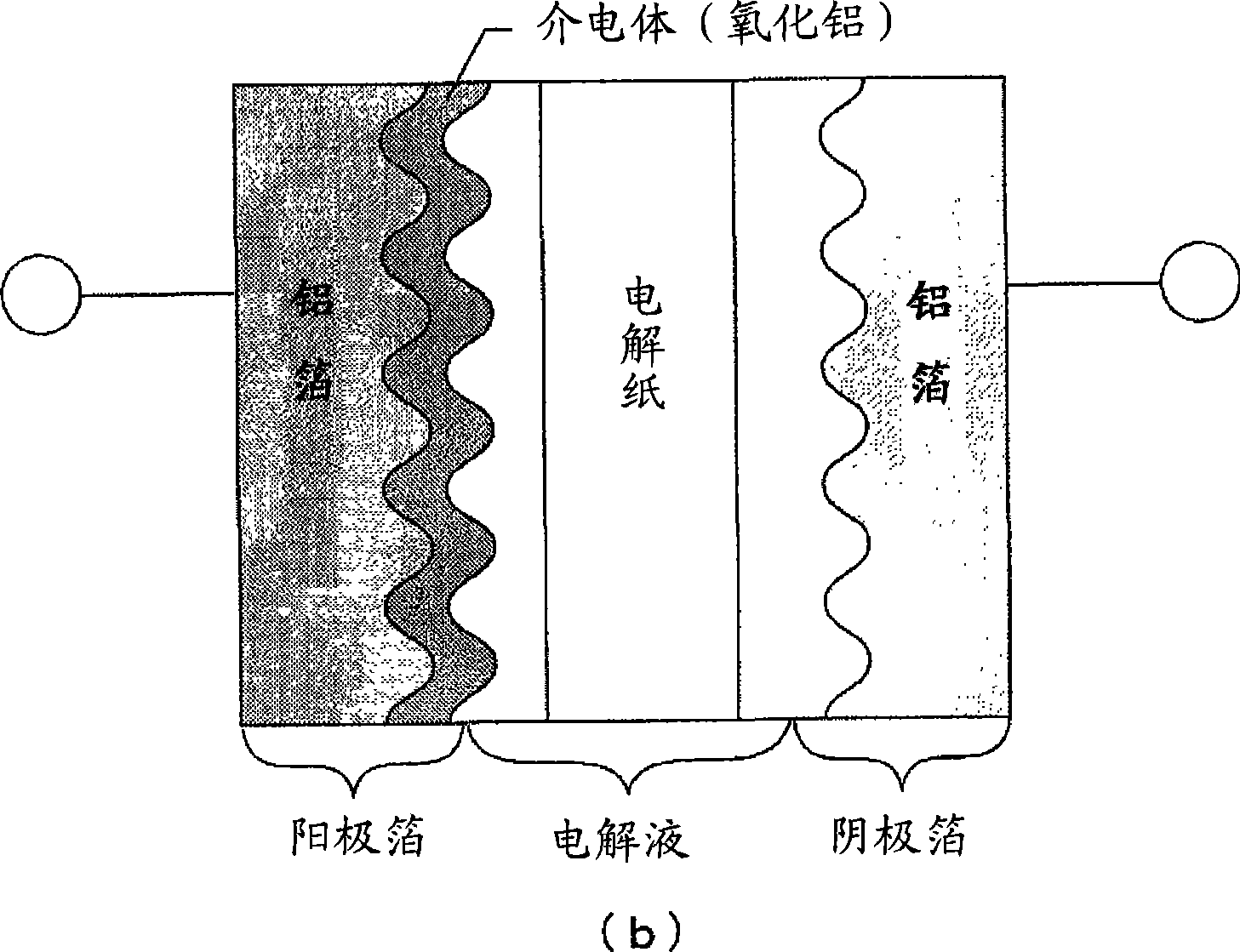

A technology of ionic compounds and cations, applied in the fields of electrolytic capacitors, electrolyte materials, and electrolytes, which can solve problems such as easy leakage, inability to exert electrolyte performance, and disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0348] Add 41.2 g (0.24 mol) of silver nitrate and 250 ml of ion-exchanged water to a flask equipped with a thermometer, a nitrogen inlet tube, a reflux condenser, a stirring device, and a dropping funnel, and stir to completely dissolve the silver nitrate. Next, a 30% aqueous solution of 26.1 g (0.20 mol) of tricyanomethyl potassium (hereinafter referred to as KTCM) was placed in a dropping funnel, and the silver nitrate solution was added dropwise at room temperature over 1 hour. The obtained white solid was filtered and washed with 300 ml of ion-exchanged water. This washing procedure was repeated 5 times.

[0349] Next, add 300ml of ion-exchanged water to the white solid, put it into a separation flask and stir, thus forming a slurry, and here, 27.3g (0.15mol) of triethylammonium bromide charged in the dropping funnel A 50% aqueous solution was added dropwise over 1 hour at room temperature. After further stirring at room temperature for 1 hour, the resulting reaction so...

Embodiment 2

[0351] The ion-exchange resin (product name: Amberlite IR120-H (120ml)) fully washed with ion-exchange water is filled in the column, and KTCM19.3g (0.15mol) 0.2mol / l aqueous solution is passed through for 4 hours. . The obtained aqueous solution was put in a beaker, and a 50% methanol solution of 30.2 g (0.30 mol) of triethylamine was added thereto at room temperature. After stirring for 30 minutes, the obtained aqueous solution was concentrated by an evaporator to obtain 28.5 g (0.15 ml) of TEATCM. The yield was 99%.

Embodiment 3

[0353] In Example 2, except that triethylamine was changed to pyridine, the same method was used to obtain pyridinium tricyanomethide. The yield was 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com