Metalization hatch method for cadmium telluride passivating film of mercury cadmium telluride infrared detecting chip

A technology of infrared detection and mercury cadmium telluride, which is applied in metal material coating technology, electrical components, climate sustainability, etc., can solve the problems of increasing process steps, difficult to control the end of metallization opening, and limiting surface treatment options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

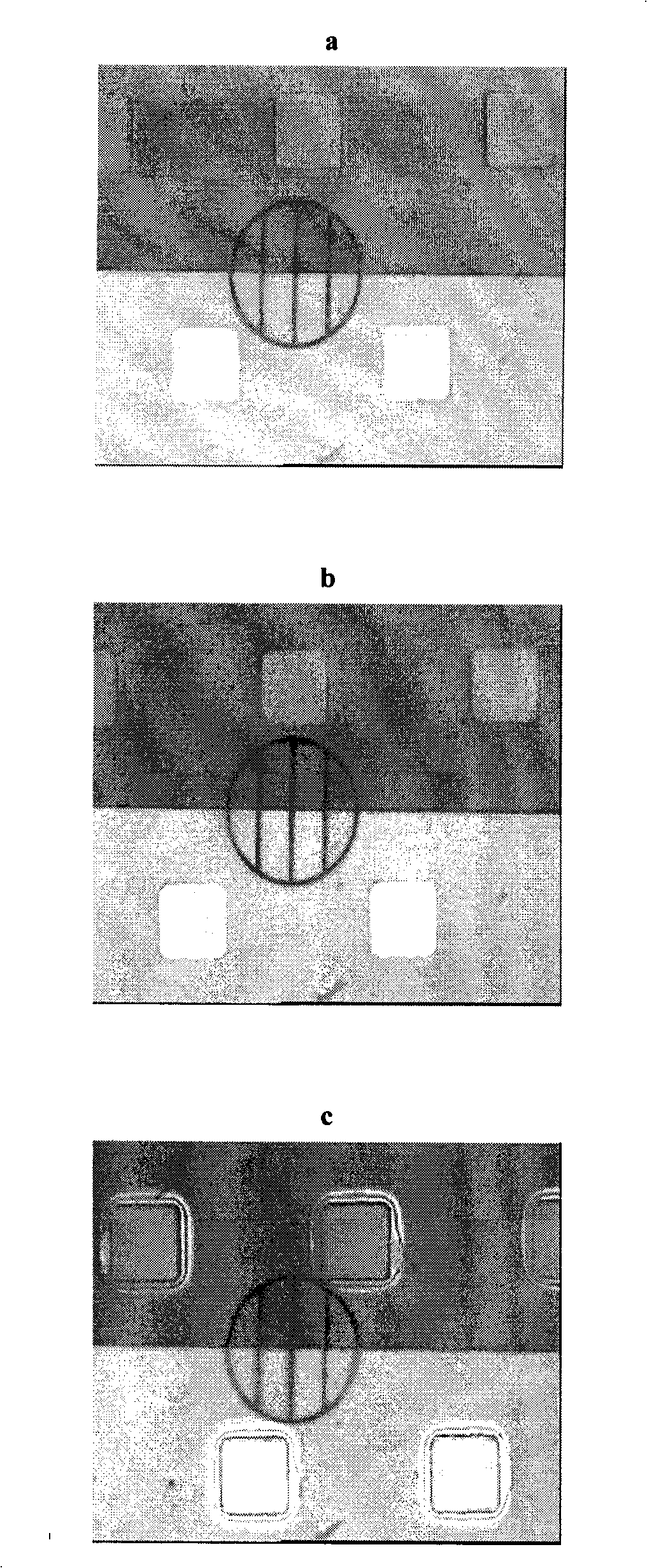

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention is described further below:

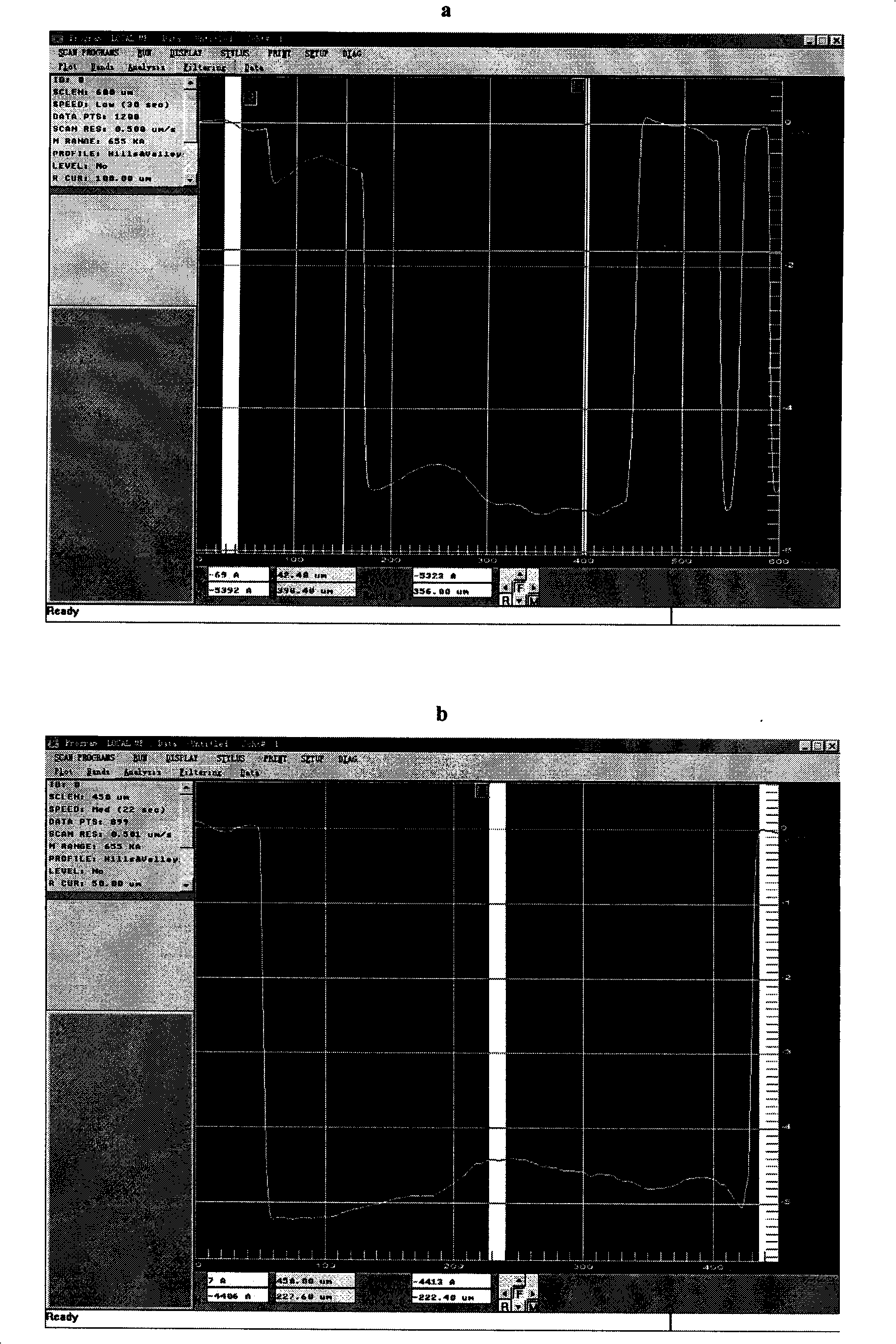

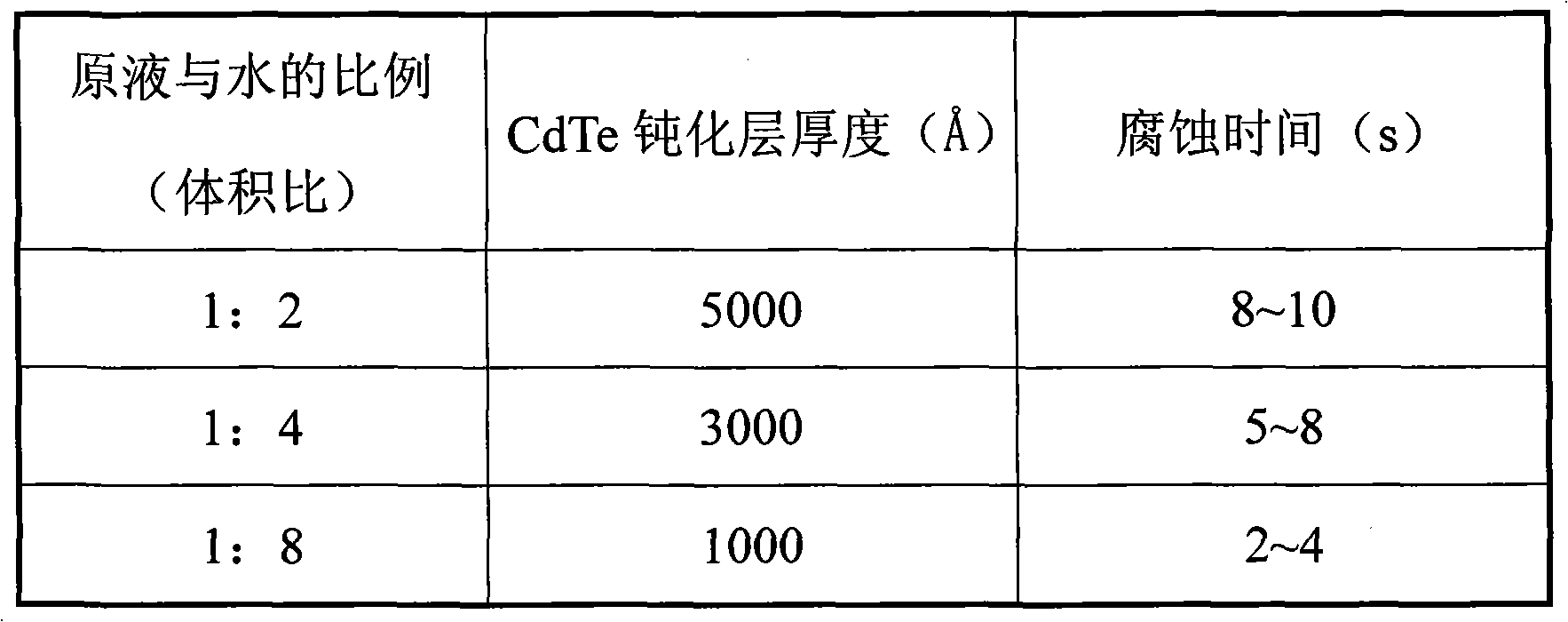

[0024] Take the metallized opening of a CdTe / ZnS bilayer passivated sample as an example. The passivation films of the samples were all grown by electron beam evaporation, and the growth rate was The final growth thickness shows CdTe All kinds of chemistry are of MOS grade, and the solution is prepared using a bottle-top pipette with an accuracy of 0.1ml, and the required dose is directly measured from the reagent bottle.

[0025] The specific implementation steps are as follows:

[0026] A. First place a clean Petri dish and filter paper on the electronic balance, and zero the displayed mass. Align the mouth of the reagent bottle containing potassium dichromate with the filter paper at the side and down, and the light body of the bottle allows the reagent to fall evenly into the petri dish lined with filter paper. until the desired dose is reached.

[0027] B. Place the fluoroplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com