Modified conjugated diene polymer and method for producing the same

A conjugated diene and a manufacturing method technology, applied in the field of modified conjugated diene-based polymers, can solve the problems of poor processability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

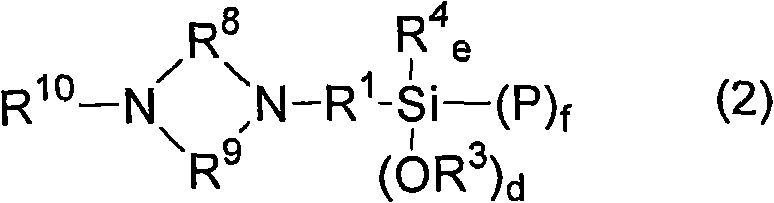

[0211] An autoclave having a stirrer and a jacket and capable of temperature control with an inner volume of 10 liters was used as a reactor. 625g of butadiene, 225g of styrene, 5500g of cyclohexane, and 0.82g of 2,2-bis(2-tetrahydrofuryl)propane as polar substances were added to the above-mentioned reactor, and the reactor was filled with The temperature was kept at 30°C. A cyclohexane solution containing 6.75 mmol of n-butyl lithium was supplied as a polymerization initiator into the reactor. After the reaction started, the exothermic heat generated by the polymerization started to raise the temperature in the reactor. 7 minutes to 12 minutes after the addition of the polymerization initiator, 50 g of butadiene was additionally supplied at a rate of 10 g / min. As a result, the temperature in the final reactor reached 77°C. After the polymerization reaction was terminated, 13.5 mmol of 1-[3-(triethoxysilyl)-propyl]-4-methylpiperazine was added to the reactor, and stirred at...

Embodiment 2

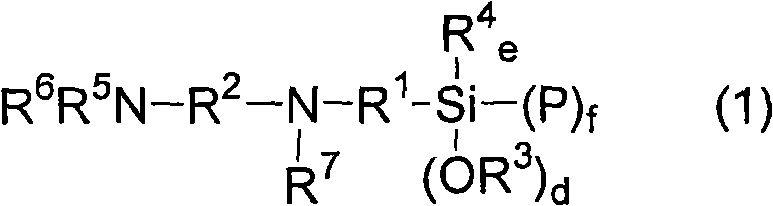

[0214] Use N-[2-(trimethoxysilyl)-ethyl]-N,N',N'-trimethylethane-1,2-diamine instead of 1-[3-(triethoxy A styrene-butadiene copolymer (sample B) having a modified component was obtained in the same manner as in Example 1 except that silyl)-propyl]-4-methylpiperazine.

[0215] (Sample B) was analyzed, and the results were as follows: the amount of bound styrene was 25% by weight, the amount of bound butadiene was 75% by weight, and the Mooney viscosity of the polymer was 54. The 1,2-bonding amount in the microstructure of the butadiene part is 60%, the polystyrene-equivalent molecular weight has a weight average molecular weight (Mw) of 390,000, a number average molecular weight (Mn) of 280,000, and a molecular weight distribution (Mw / Mn) was 1.39. In addition, the modification rate was 78%.

Embodiment 3

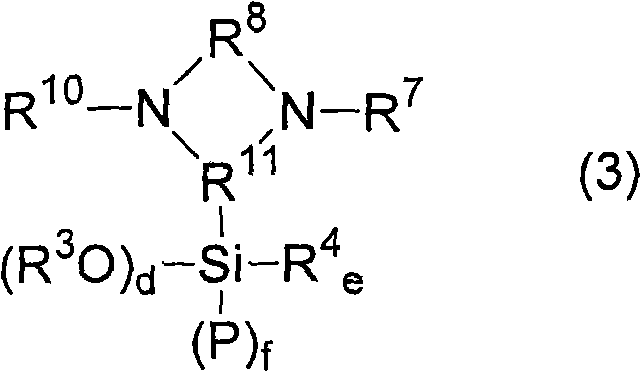

[0217] Using 2-(trimethoxysilyl)-1,3-dimethylimidazolidine instead of 1-[3-(triethoxysilyl)-propyl]-4-methylpiperazine, except Except for this, a styrene-butadiene copolymer (sample C) having a modified component was obtained in the same manner as in Example 1.

[0218] (Sample C) was analyzed, and the results were as follows: the amount of bound styrene was 25% by weight, the amount of bound butadiene was 75% by weight, and the Mooney viscosity of the polymer was 52. The 1,2-bonding amount in the microstructure of the butadiene part is 61%, and the polystyrene-equivalent molecular weight has a weight average molecular weight (Mw) of 370,000, a number average molecular weight (Mn) of 270,000, and a molecular weight distribution (Mw / Mn) was 1.37. In addition, the modification rate was 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com