Catalyst for producing epoxypropane by liquid phase one-step oxidation of propylene and preparation method

A technology of propylene oxide and catalyst, which is applied in the field of catalyst and preparation for the one-step oxidation of propylene to propylene oxide, and can solve the problems of easy loss of catalyst and degradation of catalyst reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

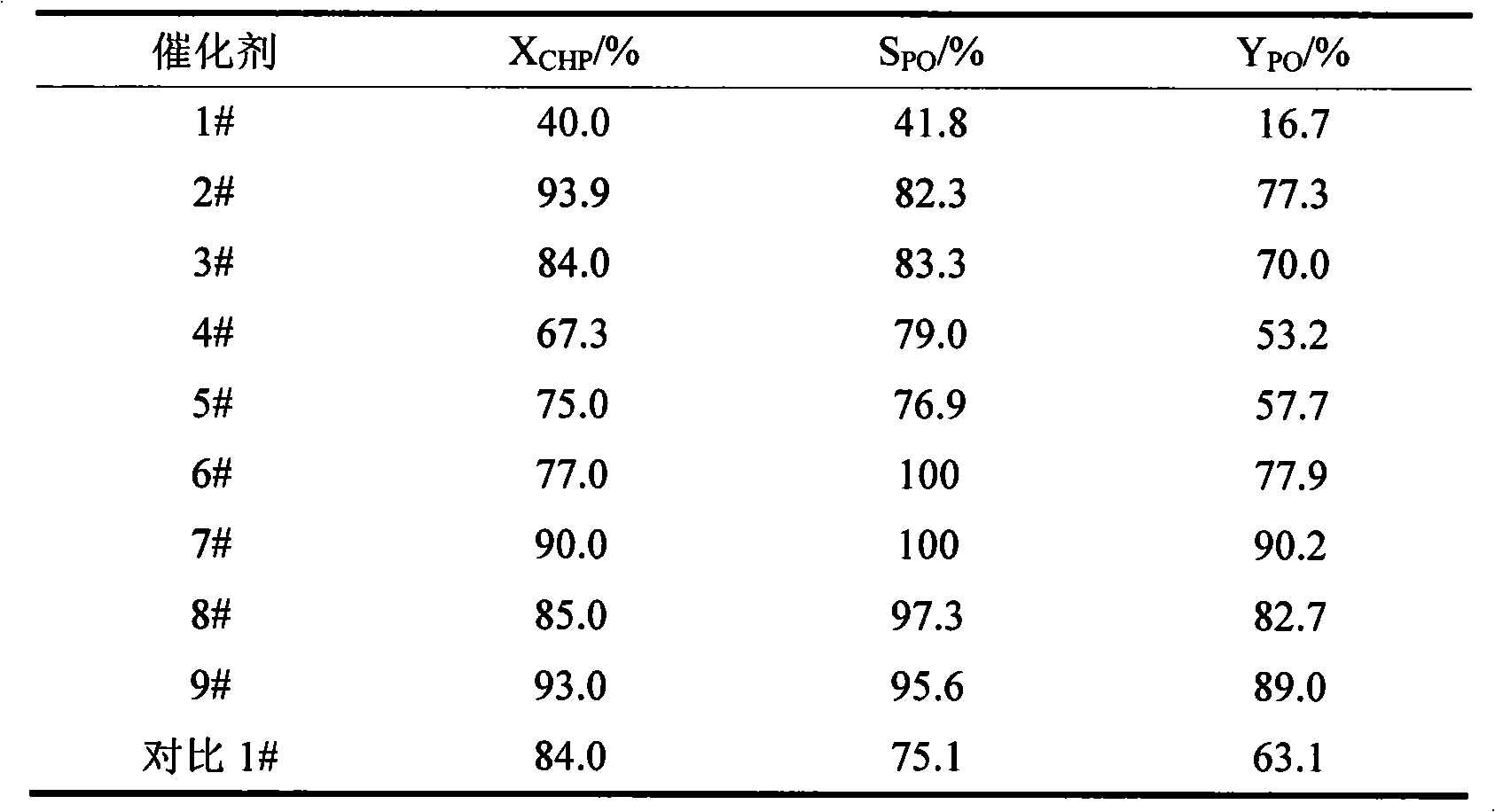

[0020] Add 20ml of tetraethyl orthosilicate (TEOS) and 20ml of absolute ethanol into the three-necked flask, then add 40ml of ammonia solution with pH=9.1, stir at 80°C for 60 minutes, then add 3ml of formamide dropwise under stirring, and then Add dropwise 40ml containing 1.2g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 0.005g ammonium chloride (NH 4 Cl) mixed aqueous solution, vigorously stirred for 10 minutes; then stood and aged at 80°C for 3h; the obtained gel was aged at room temperature for one week, dried at 100°C, ground, and roasted in air at 550°C for 5h to obtain 1# catalyst, catalyst The performance evaluation results are shown in Table 1.

Embodiment 2

[0022] NH in Example 1 4 The amount of Cl was changed to 0.02g, and other processes were the same as in Example 1 to obtain 2# catalyst, and the catalyst performance evaluation results are shown in Table 1.

Embodiment 3

[0024] NH in Example 1 4 The amount of Cl was changed to 0.04g, and other processes were the same as in Example 1 to obtain the 3# catalyst. The catalyst performance evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com