Ionic liquid double-aqueous phase system for extracting residual antibiotic in foodstuffs and use thereof

A two-phase system and ionic liquid technology, which is applied in solvent extraction, preparation of test samples, separation methods, etc., can solve the problems of no description or disclosure of the amount of ionic liquid and inorganic salt and their proportional relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

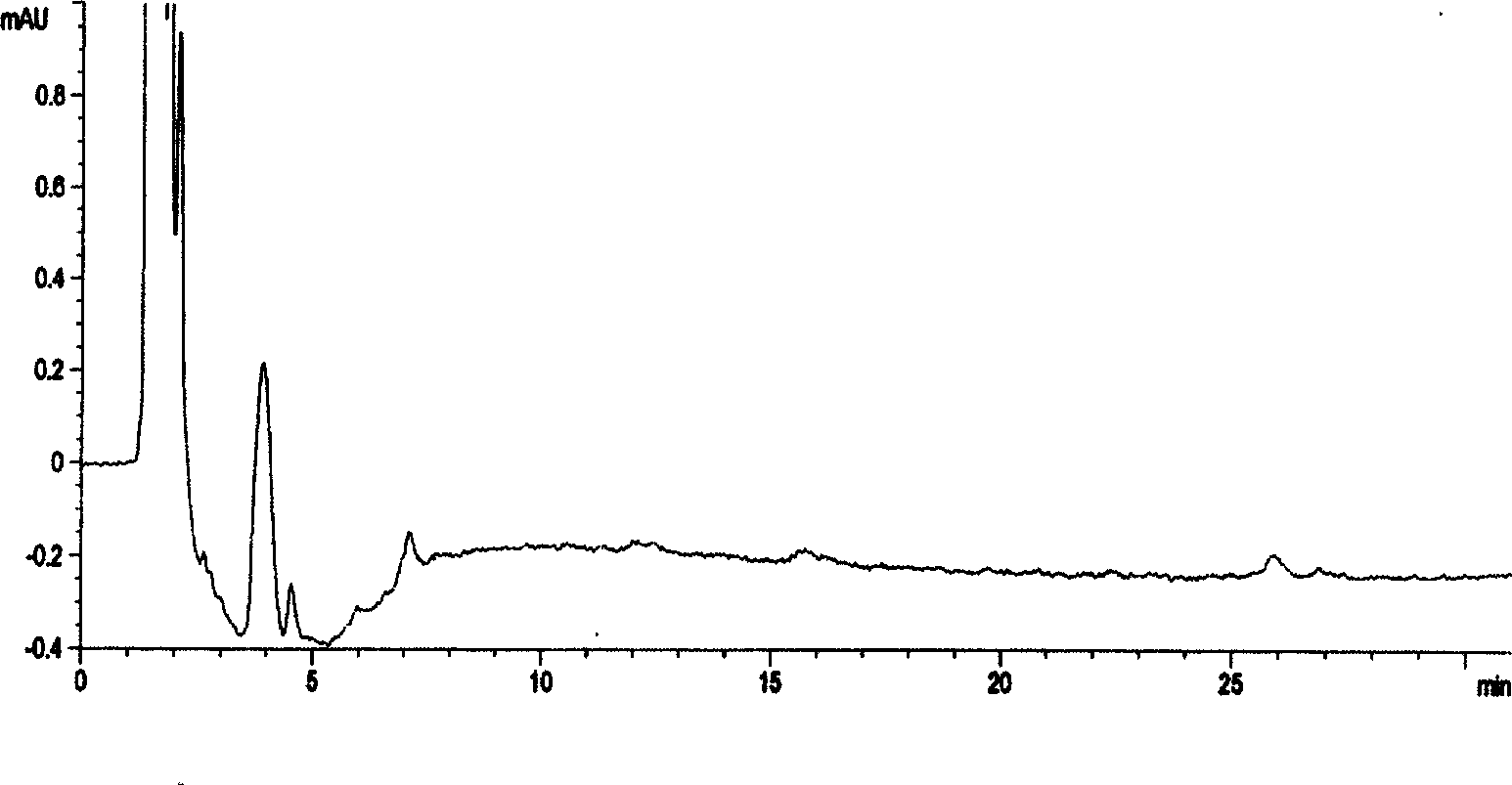

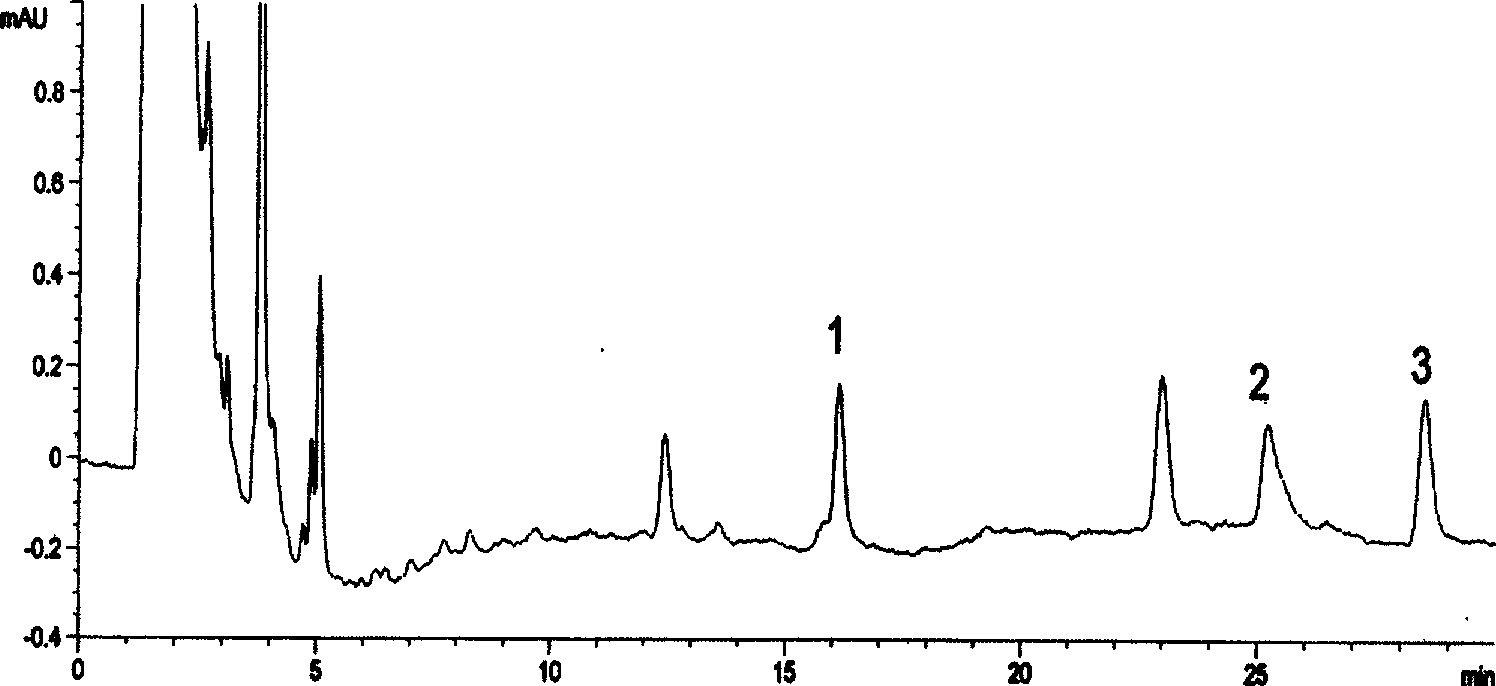

Image

Examples

Embodiment 1

[0087] The synthesis of embodiment 1 ionic liquid

[0088] Add 0.1mol of pyridine, 0.1mol of bromoethane and 15mL of cyclohexane to a 50mL two-necked flask in sequence, and stir and reflux at 30-40°C for over 24hr. The resulting product is recrystallized several times with absolute ethanol and ethyl acetate to obtain white crystals, which are alkyl-substituted pyridinium ions ([RPy] + ), the product purity is greater than 98%. The product has passed FT-IR, 1 H-NMR and 13 C-NMR characterization.

[0089] According to the above-mentioned same preparation method, use raw material 2-picoline or 4-picoline instead of pyridine to obtain alkyl-substituted 2-picoline ion ([R, 2-MPy] + ) or alkyl-substituted 4-methylpyridinium ion ([R, 4-MPy] + ).

Embodiment 2

[0090] The detection of chloramphenicol in embodiment 2 eggs

[0091] Pretreatment of egg samples:

[0092]Accurately weigh 5 g of broken egg liquid into a 25 ml centrifuge tube, add 0.05 μg of chloramphenicol (the content of chloramphenicol is 10 μg / kg broken egg liquid), then add pH 7.0, NaCl concentration of 40 g / L phosphate buffer and mix Extraction solution 3ml, which contains methanol 100μl. Vortex to mix and then centrifuge at a speed of 10,000r / min. After centrifugation, transfer the supernatant to another centrifuge tube, and then add 3ml of the above-mentioned mixed extraction solution to the lower layer. After repeating the above operation, combine the supernatant and blow off the methanol. stand still. Add 3ml of n-hexane, vibrate and centrifuge, repeat the operation 2-3 times, discard the upper layer, and dilute to 5ml with ultrapure water to prepare an egg standard sample solution, a broken egg sample solution with a chloramphenicol content of 10 μg / kg.

[009...

Embodiment 3

[0097] Example 3 Detection of Chloramphenicol in Eggs

[0098] According to the same method as in Example 2, the egg sample liquid to be tested with a chloramphenicol content of 20 μg / kg, 40 μg / kg and 200 μg / kg was obtained, and the same ionic liquid-inorganic salt and detection method as in Example 2 were used for detection. .

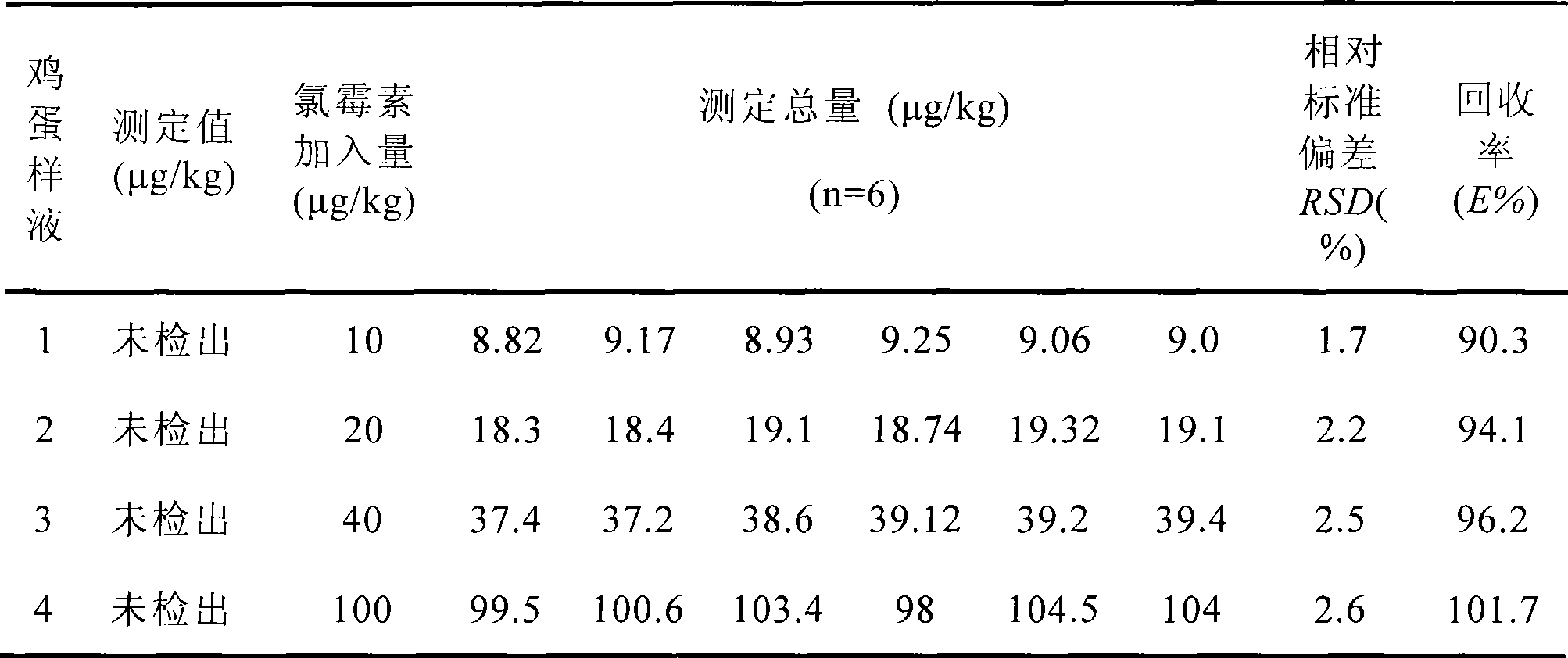

[0099] Through analysis and calculation (that is, on the standard curve with the concentration as the abscissa and the peak area as the ordinate, the corresponding sample concentration is determined according to the measured peak area), and the analysis and detection results of the four concentrations are shown in Table 1.

[0100] Table 1 Determination results of chloramphenicol in egg samples

[0101]

[0102] Ionic liquid ethylpyridine bromide ([EPy]Br) and K 2 HPO 4 The extraction rate of chloramphenicol in the broken egg liquid is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com