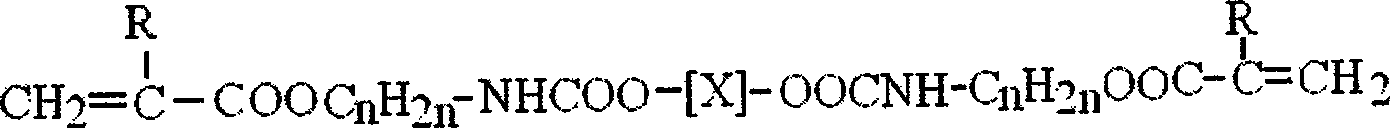

Highly oxygen-permeable fluorosiloxanes aquogel contact lens material and preparation thereof

A technology of high oxygen permeability fluorosiloxane and fluorosiloxane, applied in glasses/goggles, instruments, optics, etc., can solve problems affecting the oxygen permeability of contact lenses and achieve good oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Synthesis of Epoxy Terminated Compound R

[0044] Weigh 10g allyl glycidyl ether in a flask, N 2 Protect, heat to 90 degrees, add chloroplatinic acid catalyst to make 1ml chloroplatinic acid isopropanol solution, slowly add 3g tetramethyldihydrosiloxane into the flask in a constant pressure dropping funnel with magnetic stirring, and reflux for 15h. Toluene was removed by rotary evaporation. Finally, distill under reduced pressure, collect the fraction with a boiling point of 150-155°C / 2mmHg, and obtain a light yellow transparent liquid product, which is the epoxy-terminated product R, whose structural formula is

[0045]

Embodiment 2

[0047] Synthesis of capping agent X

[0048] Weigh 10g of epoxy-terminated product R, add excess n-hexanol 50ml and 100ul trifluoromethanesulfonic acid, stir magnetically, reflux at 65°C for 24h, remove methanol by rotary evaporation to obtain light yellow product X, whose structural formula is

[0049]

Embodiment 3

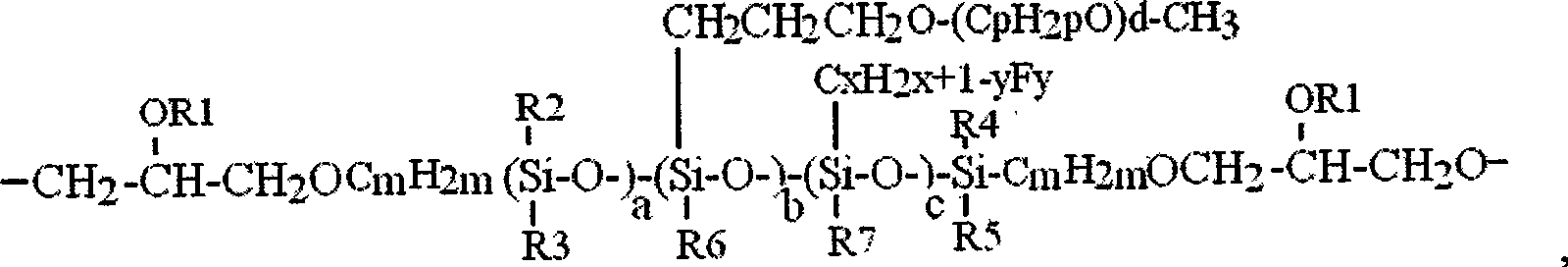

[0051] Synthesis of Polymers Containing Silicon-Hydrogen Bonds (A)

[0052] 200g octamethylcyclotetrasiloxane (D4), 5g tetramethyltetrahydrocyclotetrasiloxane (D4H), 5g 1,3,5-trimethyltrifluoropropylcyclotrisiloxane (D3F), 4g of capping agent X was dissolved in a round bottom flask by adding 500ml of chloroform, stirred magnetically, added 1g of trifluoromethanesulfonic acid as a catalyst, and reacted for 10h at room temperature, washed and layered repeatedly with distilled water until the system was neutral, and the organic compound of the lower layer was obtained. phase, rotary evaporation removes chloroform to obtain a product with a certain viscosity, and removes volatile matter under reduced pressure to obtain a colorless and transparent liquid with a certain viscosity, which is product (A), and its structural formula is

[0053]

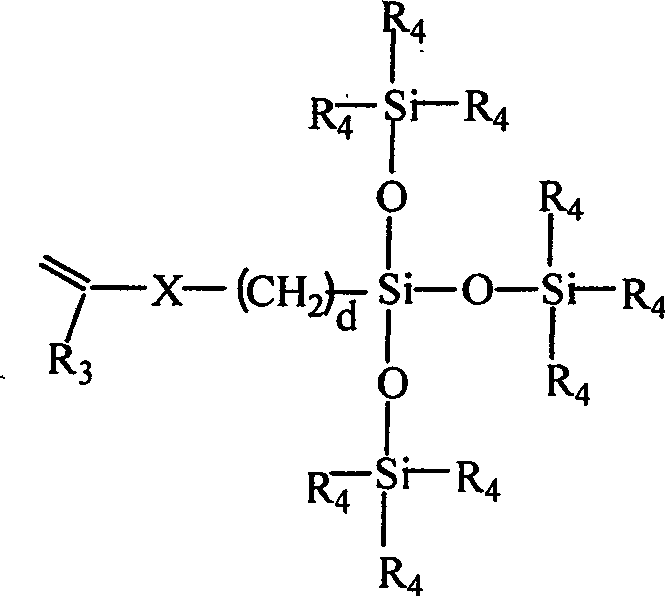

[0054] , where Y's are:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com