Lutein solid dispersoid and preparation method thereof

A technology of solid dispersion and lutein, applied in the field of medicine, can solve the problems of inability to take into account stability and water dispersibility, low drug loading, etc., and achieve the effects of improving bioavailability, easy operation and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Dissolve 5g of high-purity lutein crystals and 250g of β-cyclodextrin in 6000ml of ethanol, heat it to 45°C and keep it warm, stir for 1 hour, and evaporate the ethyl acetate. After the reaction, quickly cool down to 4°C, solidify, and dry in vacuum. After embrittlement, take it out and pulverize it through an 80-mesh sieve.

[0054] Phase solubility test:

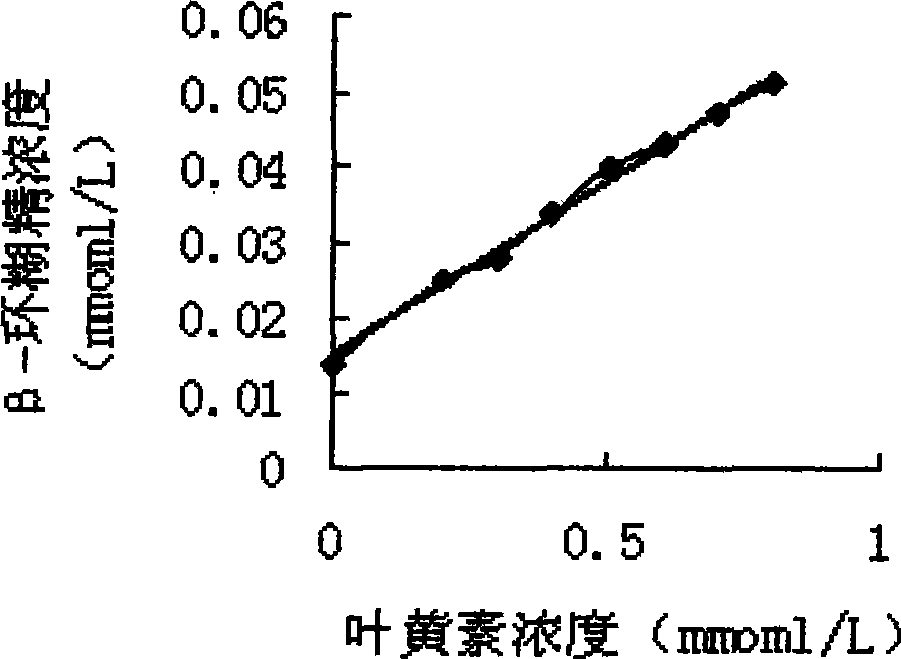

[0055] Use different concentrations of β-cyclodextrin (0 ~ 1.0mmol / L) to conduct phase solubility tests on lutein, and the dissolution curve of lutein can be obtained. The results are shown in figure 1 . The curve has a good linear increasing trend, indicating that after β-cyclodextrin and lutein form a solid dispersion, its solubility increases with the increase of β-cyclodextrin concentration. The dissolution curve and correlation coefficient of lutein are: y=0.0464x+0.015 (mmol / L) R2=0.9932.

Embodiment 2

[0057] Take 1g of lutein crystals and 30g of poloxamer in an evaporating dish, heat and stir in a water bath at 60°C until completely melted, then place the molten material under vigorous stirring in an ice-salt bath and rapidly cool it into a solid. Vacuum drying, grinding, sieving, that is.

[0058] In vitro dissolution test:

[0059] Taking lutein crystals as a control, the in vitro dissolution of the lutein solid dispersion prepared in Example 2 was measured. The results show that the cumulative dissolution rate of lutein crystals in vitro in 45 minutes is 10.8%, while the solid dispersion of the present invention can reach more than 90% (marked amount). The results showed that the dissolution of lutein solid dispersion in vitro was better than that of lutein crystals.

Embodiment 3

[0061] Dissolve 100mg of lutein crystals in 800mL of isopropanol, heat 10g of polyethylene glycol 4000 to a molten state, add the lutein solution into β-cyclodextrin and stir well, after the isopropanol is completely removed, quickly Cool to 10°C, dry in vacuum for 3 hours, grind, and sieve to obtain the product.

[0062] Stability test:

[0063] Take 100 g of the lutein solid dispersion prepared in Example 3, and 100 g of the same batch of lutein crystal raw materials, and conduct stability investigations according to the light influence factor and high temperature influence factor test.

[0064] Light influence factor test:

[0065] Take 10g of each of the above samples and divide them into several parts, place them in a 4000LX light box, take samples at 0:00, 6:00, 12:00, 24:00, 3 days, 5 days, and 10 days to measure the absorbance value of lutein, and calculate the preservation rate.

[0066] Preservation rate = (measured absorbance / initial absorbance) × 100%

[0067] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com