Preparation method of helical flexible pressure-resistance nerve conduit

A nerve conduit and helical technology, applied in the direction of catheters, devices with human tubular structures, etc., can solve the problems of impaired function, limited nerve sources, and it is difficult to avoid wrong nerve bundles, so as to improve speed and quality, and repair peripheral nerves. Effects of nerve damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

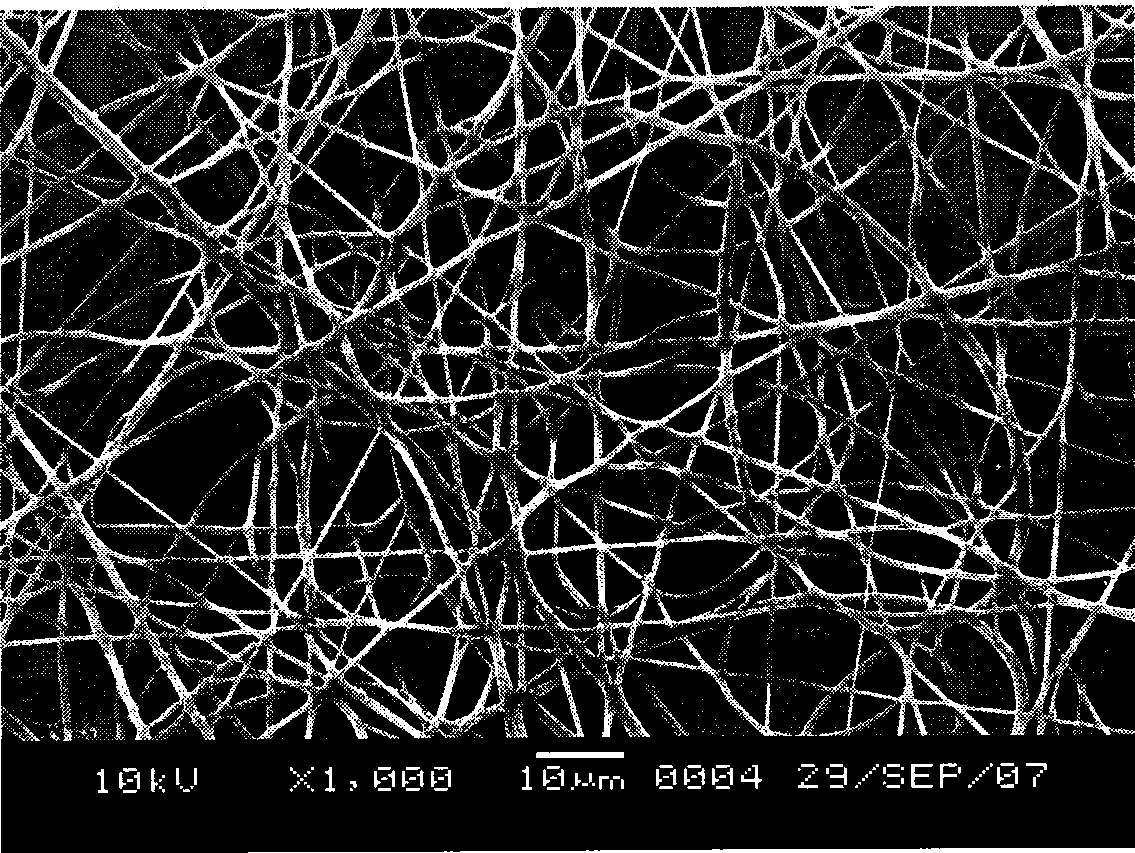

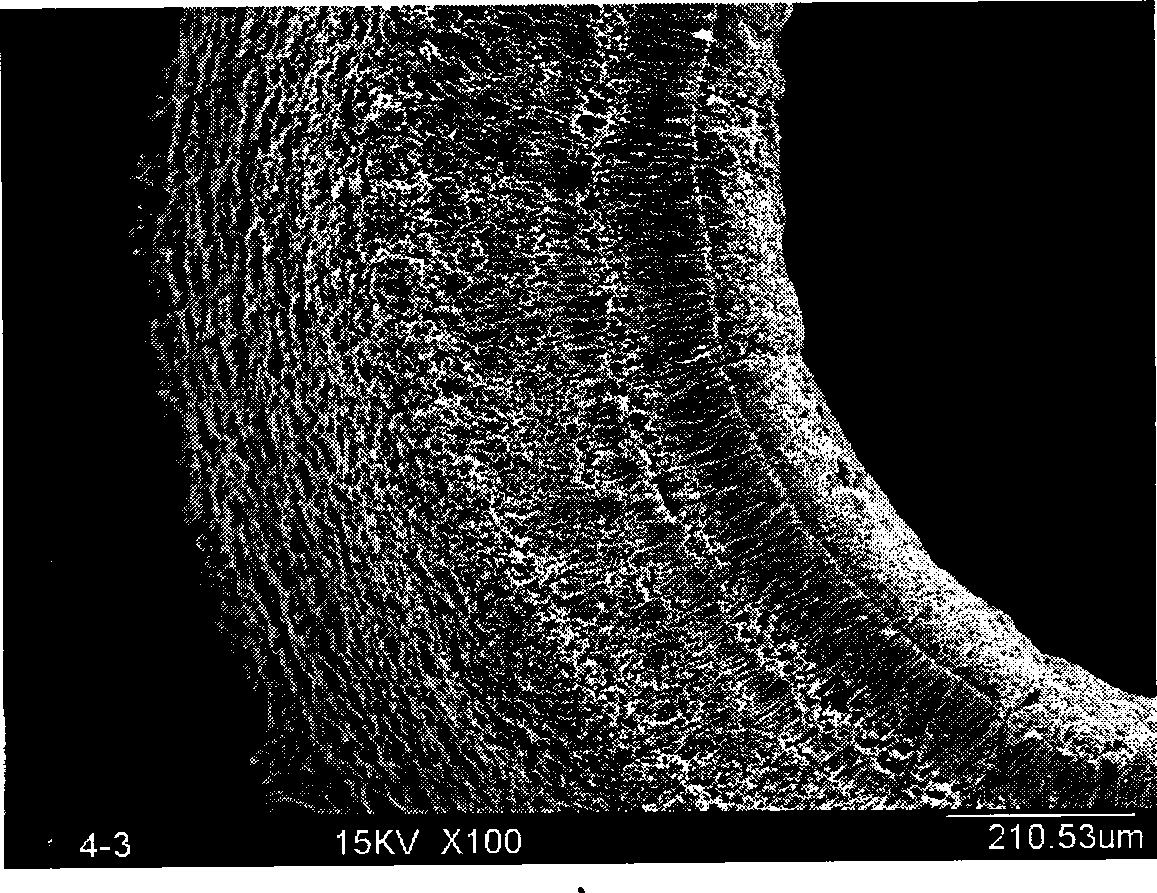

Embodiment 1

[0026] Weigh 0.6g of polylactic acid-caprolactone P(LLA-CL)[75:25] with an electronic balance, dissolve it in 10mL of dichloromethane, stir and oscillate until completely dissolved. The micron fiber bundles are wound on a stainless steel tube with a diameter of 4 mm, and the distance between the fiber bundles on the stainless steel tube is 0.5 cm. Electrospinning was performed on the solution, the applied voltage was 20kv, the receiving distance was 15cm, the spinning speed was 1.0mL / h, the diameter of the spinneret was 0.9mm, and the rotational speed of the receiving shaft was 1000r / m. P(LLA-CL) nerve guides are available in a 4mm diameter helix.

example 2

[0028] Weigh 0.8 g of collagen with an electronic balance, dissolve it in 10 mL of hexafluoroisopropanol, stir and oscillate until completely dissolved. The micron fiber bundles are wound on a stainless steel tube with a diameter of 4 mm, and the distance between the fiber bundles on the stainless steel tube is 0.3 cm. Electrospinning was performed on the solution, the applied voltage was 18kv, the receiving distance was 15cm, the spinning speed was 1.0mL / h, the diameter of the spinneret was 0.9mm, and the rotational speed of the receiving shaft was 1500r / m. Collagen nerve guides are available in a helical shape with a diameter of 4 mm.

example 3

[0030] Weigh 0.6 g of polylactic acid PLLA with an electronic balance, dissolve it in 10 mL of trifluoroethanol, stir and oscillate until completely dissolved. The micron fiber bundles are wound on a stainless steel tube with a diameter of 3 mm, and the distance between the fiber bundles on the stainless steel tube is 0.3 cm. Electrospinning was performed on the solution, the applied voltage was 17kv, the receiving distance was 12cm, the spinning speed was 1.0mL / h, the diameter of the spinneret was 0.9mm, and the rotational speed of the receiving shaft was 1000r / m. PLLA nerve guides are available in helical shapes with a diameter of 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com