High-speed composting process and apparatus

A composting, high-speed technology, applied in fertilization devices, organic fertilizers, preparation of organic fertilizers, etc., can solve the problems of high production price, waste complexity, time and degradation degree limitations, and achieve the effect of improving fertilizer preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

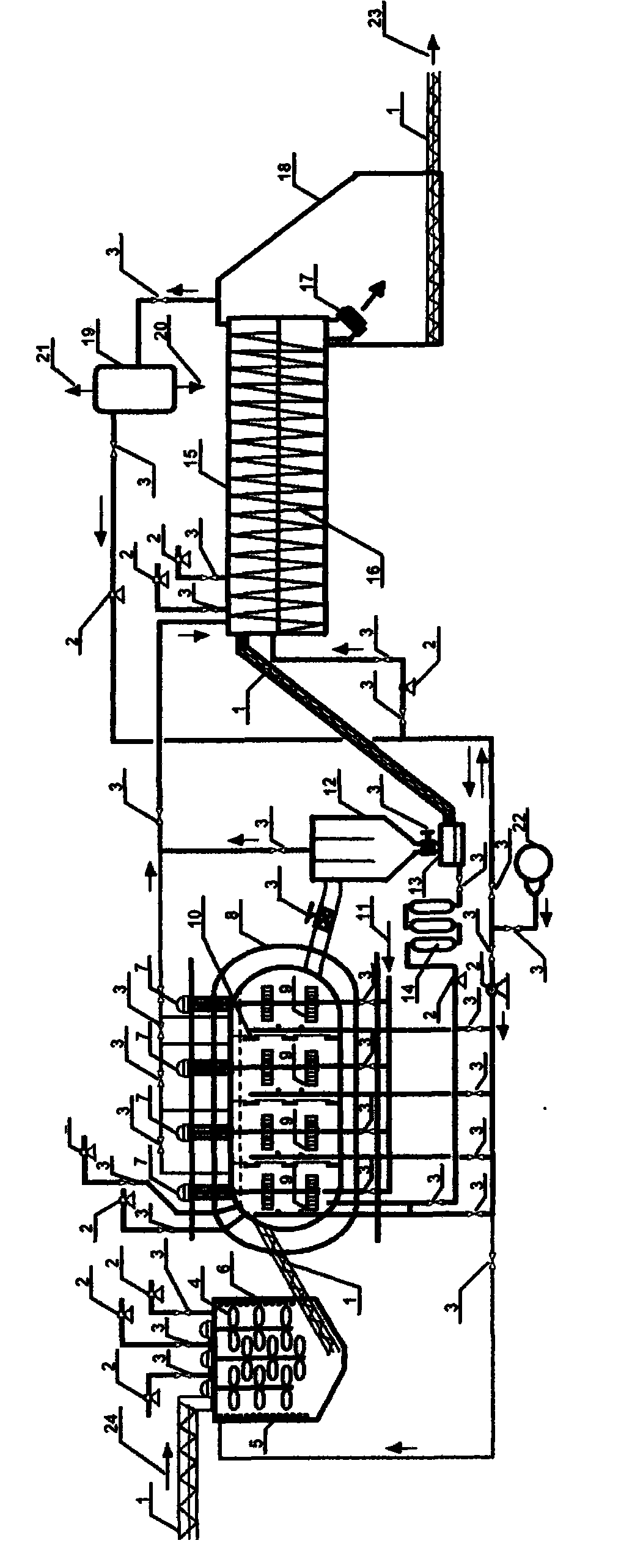

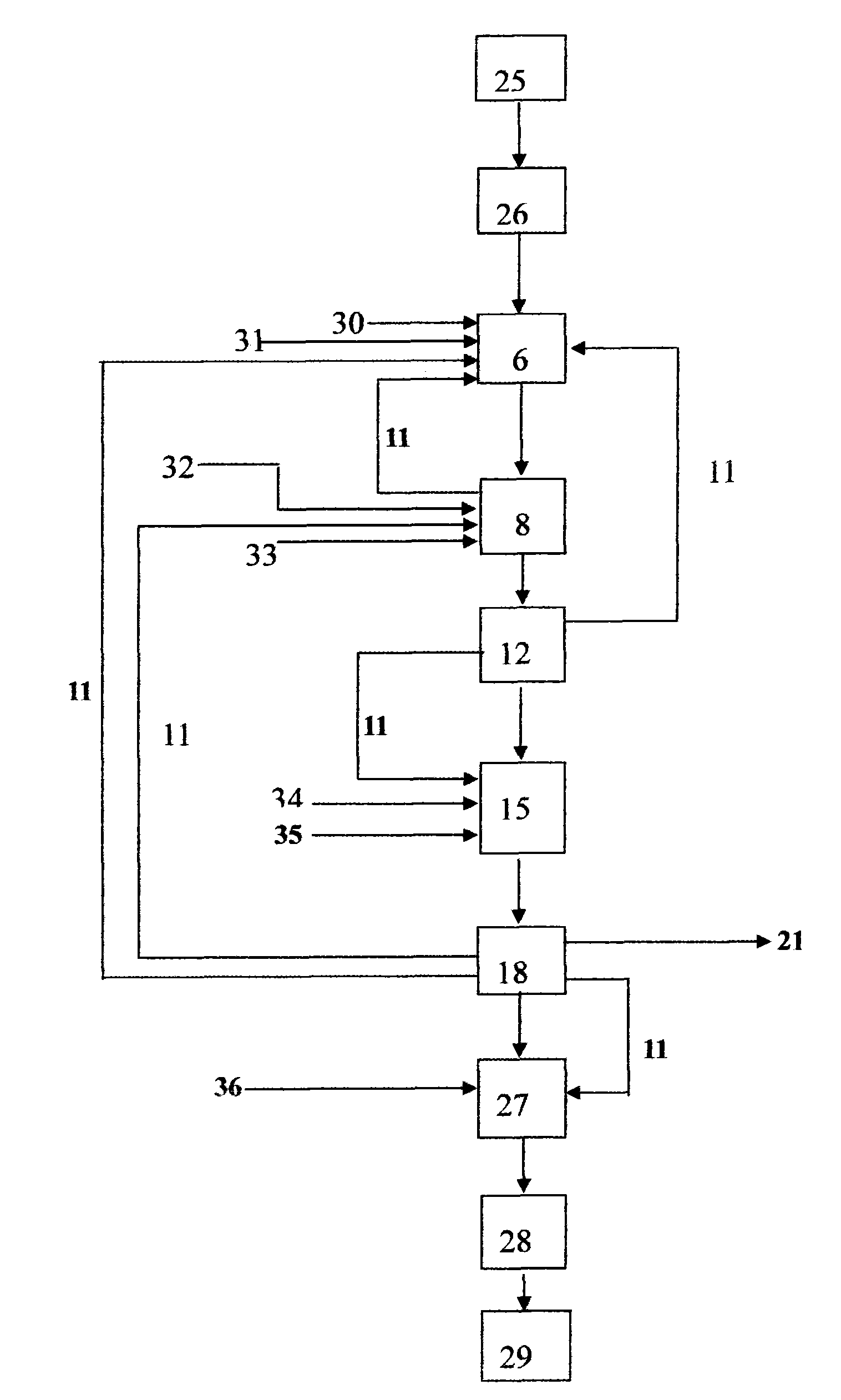

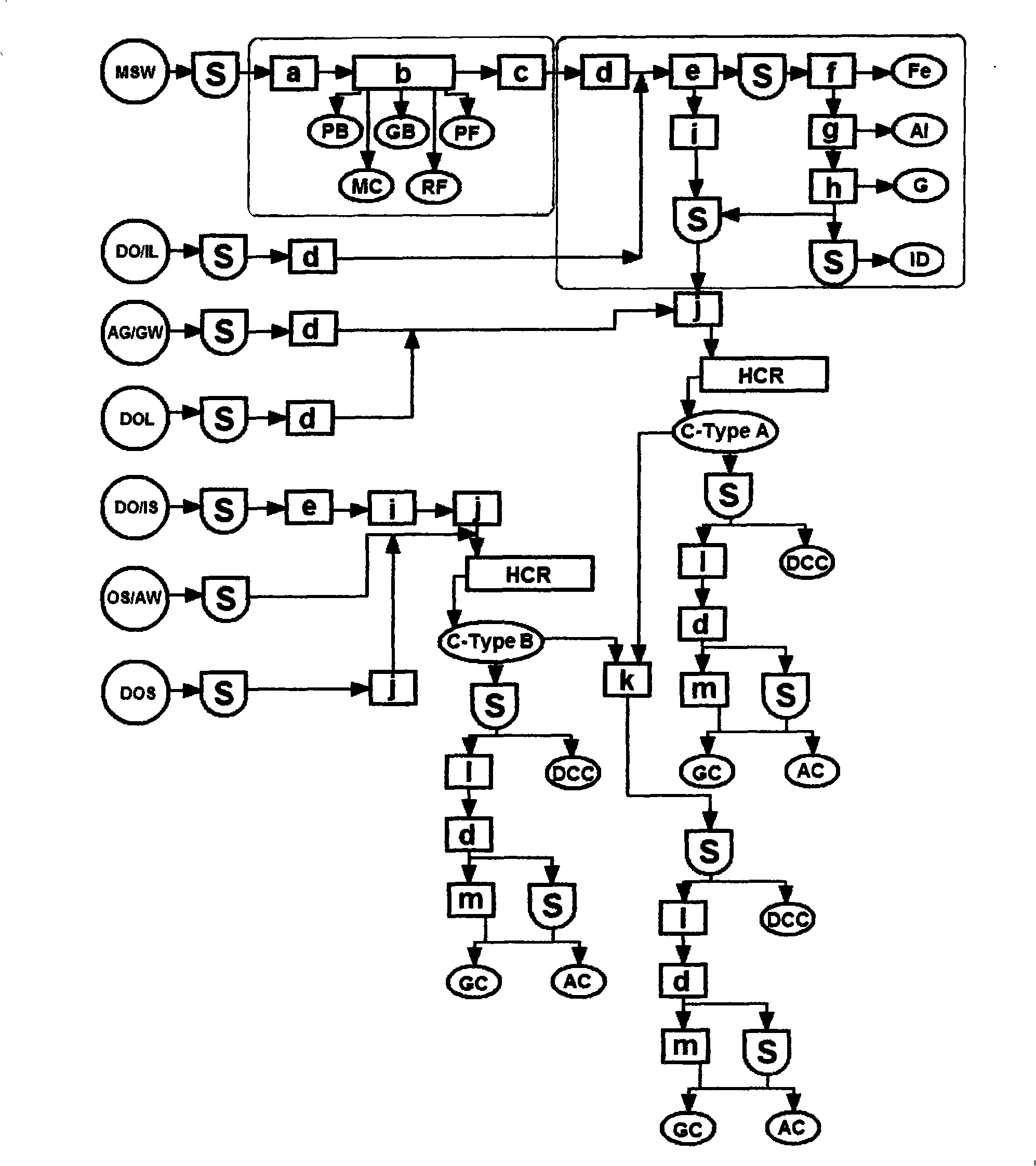

Method used

Image

Examples

Embodiment 1

[0067] The sludge of a brewery in Guangdong Province was tested to contain 2.4% N (based on dry weight), P 2 O 5 2.1% (based on dry weight), K 2 O 0.6% (by dry weight), organic matter (C) 39.0% (by dry weight), cellulose 18% (by dry weight), heat content 3000Kcal / Kg, moisture content 85%, heavy metal content is much lower Urban waste agricultural control standards. This sludge can be used as a compost material. However, due to the foul odor, high viscosity, and high water content of the sludge, it is difficult to directly use the traditional composting method without drying. The cellulose content is so low that high-quality organic compost cannot be produced.

specific Embodiment approach

[0068] If the high-speed activation composting method is used, the product quality can be improved and the production operation can be easily carried out. The specific implementation is as follows:

[0069] The sludge and straw are mixed at a ratio of 1:1. Because these two kinds of raw materials are all natural products and no chemicals are added, this kind of mixed feed can produce compost and compound fertilizer for higher-value organic food crops. Important physical and chemical indicators can be analyzed before compost manufacturing, such as BOD 5 , COD, fertilizer, heat content, humidity, etc. And calculate BOD 5 The relationship between COD can be used to check COD analysis results during operation, control the residence time of the high-speed stable kettle, and predict the remaining content of easily degradable organics after treatment.

[0070] First, the straw and the bentonite equivalent to 1% (weight) of the straw are added to the cutting machine and cut to a particle...

Embodiment 2

[0075] A city is looking for ways to harmless, reduce and recycle waste in order to achieve the goal of sustainable development and have the highest economic benefits to simultaneously treat its municipal solid waste and sewage treatment plant sludge. After comparing the existing sanitary landfill method, incineration power generation method, and traditional composting method, it is found that there are secondary pollution problems, and if the future social cost is considered, it is not the best choice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com