Synthesis and surface decorating method of rare-earth nanometer compound material

A nanocomposite material and surface modification technology, which is applied in the synthesis and surface modification of rare earth nanocomposite materials, can solve the problems of limited photocatalytic performance improvement, limited application of titanium dioxide, weak oxidation ability, etc., and achieves good modification effect and easy composition Controlled, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

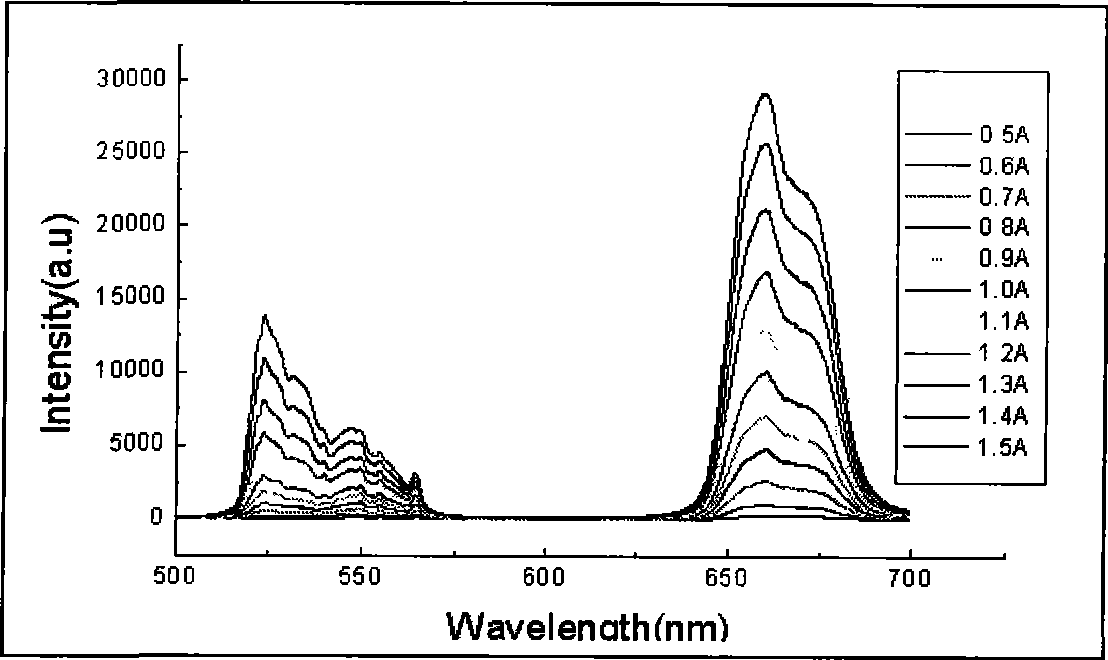

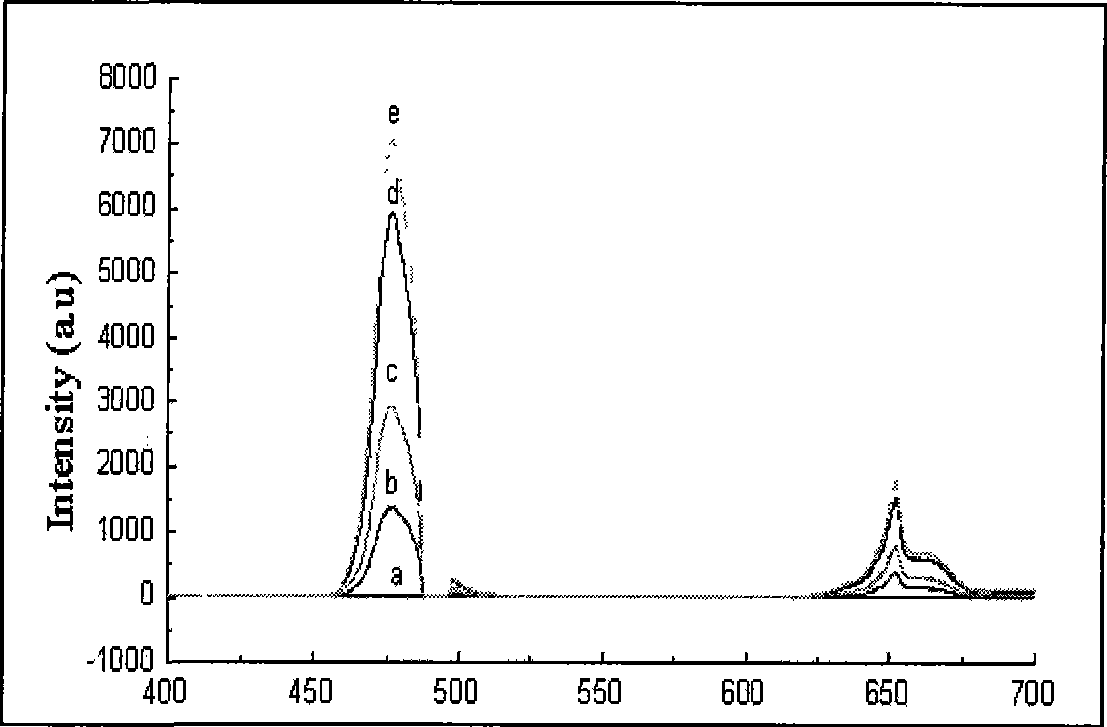

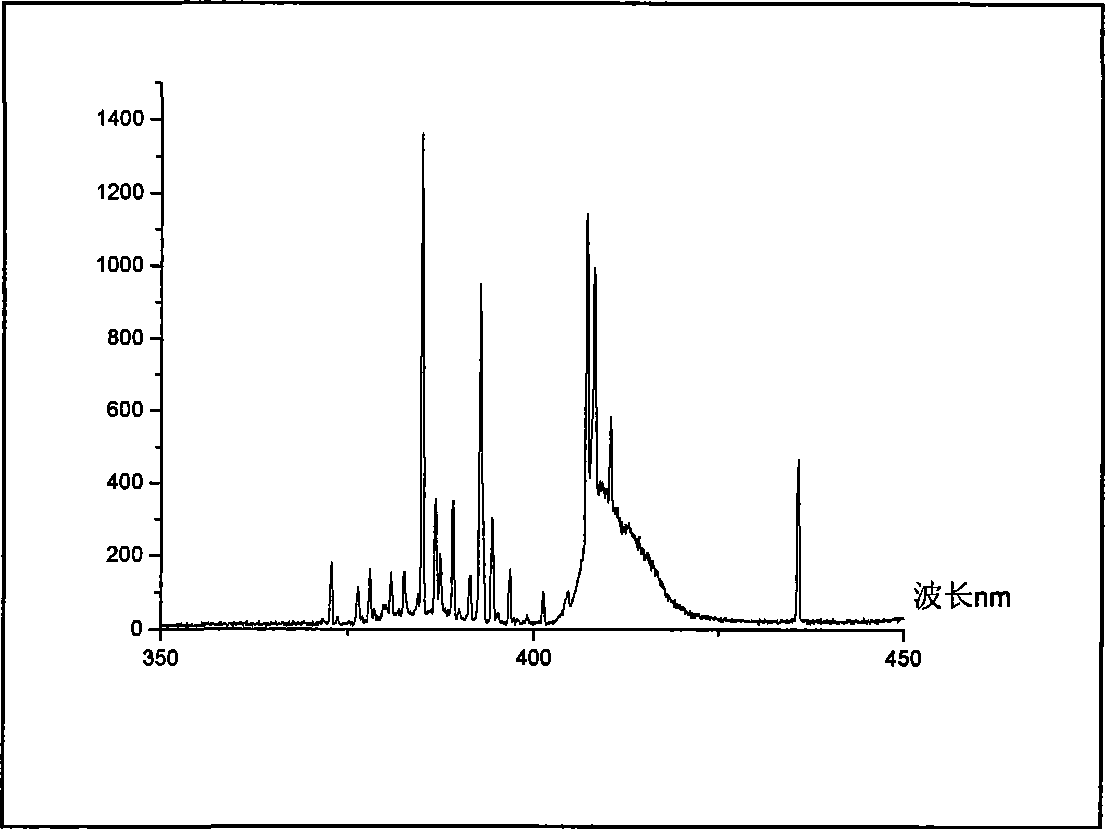

[0023] Take 16 mL of absolute ethanol, add 3.4 mL of butyl titanate, 2.0 mL of glacial acetic acid and 1.0 mL of water, stir for 30 minutes, then add 2.0 mL of Er(NO 3 ) 3 and 2.0mLYb(NO 3 ) 3 The solution was stirred vigorously for 1 hour, and the resulting gel was vacuum-dried at 60° C. for 24 hours, and then calcined in a muffle furnace at 600° C. for 4 hours to obtain Er / Yb ion-co-doped nano-titanium dioxide crystal powder.

Synthetic example 2

[0025] Take 16 mL of absolute ethanol, add 3.4 mL of butyl titanate, 2.0 mL of glacial acetic acid and 1.0 mL of water, stir for 60 minutes, then add 2.0 mL of Tm(NO 3 ) 3 and 1.0mLYb(NO 3 ) 3 The solution was stirred vigorously for 1 hour, and the resulting gel was vacuum-dried at 50° C. for 48 hours, and then calcined in a muffle furnace at 600° C. for 4 hours to obtain Tm / Yb ion-co-doped nano titanium dioxide crystal powder.

Synthetic example 3

[0027] Take 16 mL of absolute ethanol, add 3.4 mL of butyl titanate, 2.0 mL of glacial acetic acid and 1.0 mL of water, stir for 30 minutes, then add 2.0 mL of Er(NO 3 ) 3 , 2.0mLYb(NO 3 ) 3 and 2.0mL 0.01mol / L Fe(NO 3 ) 3 The solution was stirred vigorously for 1.5 hours, and the resulting gel was vacuum-dried at 60° C. for 24 hours, and then calcined in a muffle furnace at 800° C. for 4 hours to obtain Er / Yb / Fe co-doped nano titanium dioxide crystal powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com