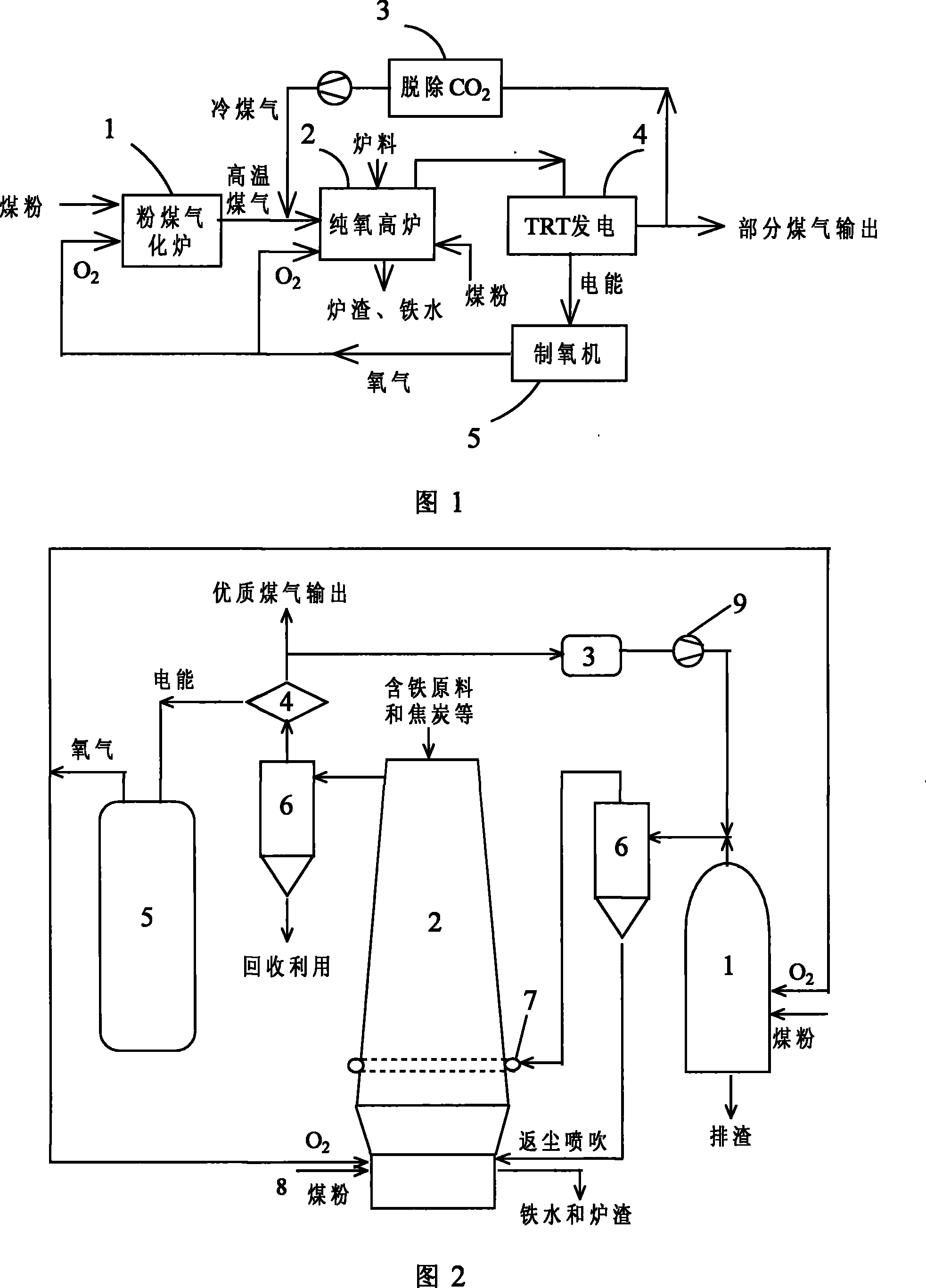

Low-coke-ratio blast furnace ironmaking technique

A technology of blast furnace ironmaking, coke ratio, applied in the direction of blast furnace, blast furnace detail, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

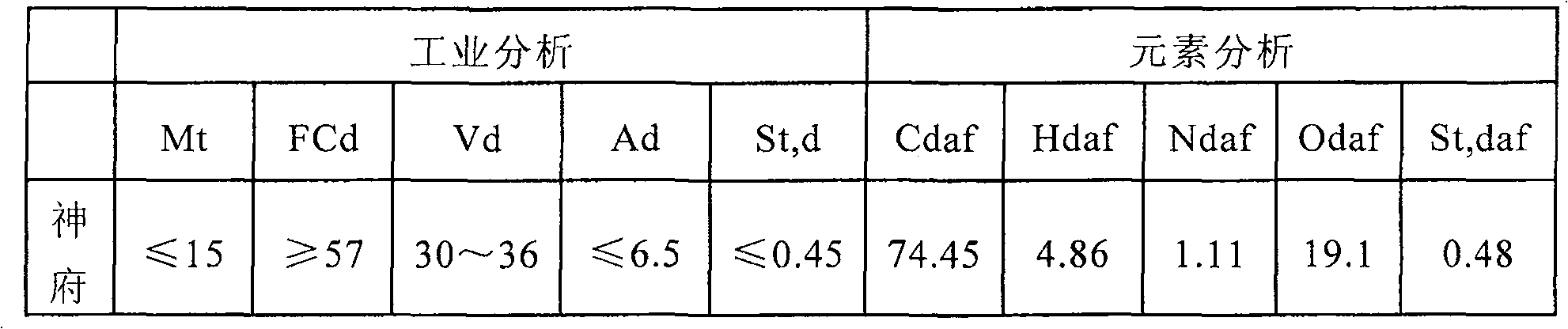

Method used

Image

Examples

Embodiment 1

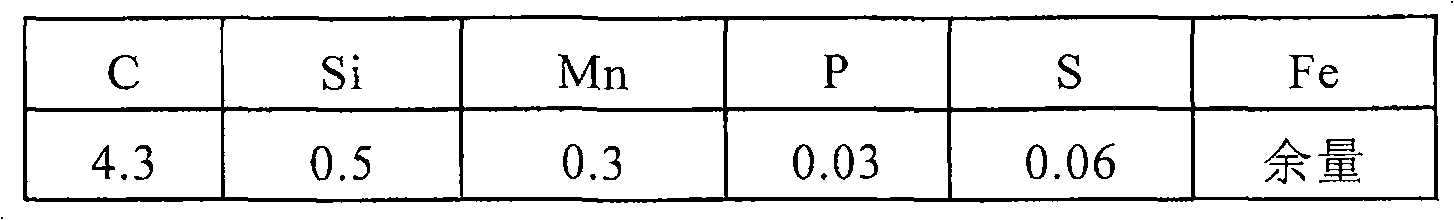

[0042] A certain 2500m 3 A high-efficiency and environment-friendly blast furnace combined with a blast furnace and a 2050t / d dry coal gasifier. The single furnace gas output of the dry coal gasifier is 164,000m 3 / h, the amount of oxygen used for pulverized coal gasification is 47400m 3 / h, the coke ratio of the blast furnace is 200kg / t, the amount of pulverized coal injected at the tuyere is 100kg / t, and the amount of oxygen blown at the tuyere is 22000m 3 / h, the amount of purified blast furnace top gas that is circulated for chilling and mixed with gas is 180,000m 3 / h, the utilization factor of the blast furnace is 3.0t / m 3 .d, the iron production of the blast furnace is 7500t per day, and the gas volume blown into the shaft is 1323m3 / t iron.

[0043] The charge structure of the blast furnace is 80% sintered ore, 10% pellet ore, 10% concentrated ore, the average grade of iron entering the furnace is 60%, the binary alkalinity of the slag is 1.15, and the secondary meta...

Embodiment 2

[0049] A certain 1250m 3 A high-efficiency and environmentally friendly blast furnace combined with a blast furnace and a 1050t / d dry coal gasifier. The single furnace gas production of the dry coal gasifier is 84,000m 3 / h, the amount of oxygen used for pulverized coal gasification is 24400m 3 / h, the coke ratio of the blast furnace is 190kg / t, the amount of pulverized coal injected at the tuyere is 100kg / t, and the amount of oxygen blown at the tuyere is 11000m 3 / h, the amount of purified blast furnace top gas that is circulated for chilling and mixed with gas is 95,000m 3 / h, the utilization factor of the blast furnace is 3.4t / m 3 .d., the daily blast furnace iron production reaches 4250t, and the amount of gas blown into the furnace body is 1322m 3 / t Iron.

[0050] The charge structure of the blast furnace is 80% sintered ore, 10% pellet ore, 10% concentrated ore, the average grade of iron entering the furnace is 60%, the binary alkalinity of the slag is 1.20, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com