Method for preparing ferroplatinum nano-particle

A technology of alloy nanoparticles and iron-platinum, which is applied in the field of nanomaterials, can solve the problems of wide particle size distribution of nanoparticles, harsh reaction conditions, and easy agglomeration of products, and achieve the effects of pollution-free by-products, low cost, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

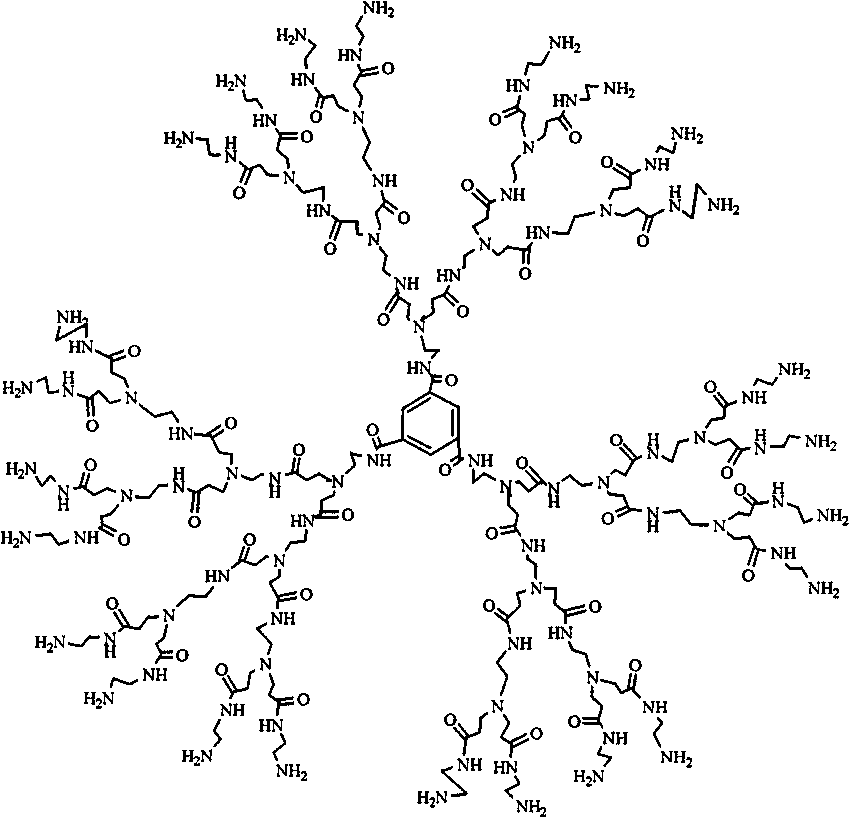

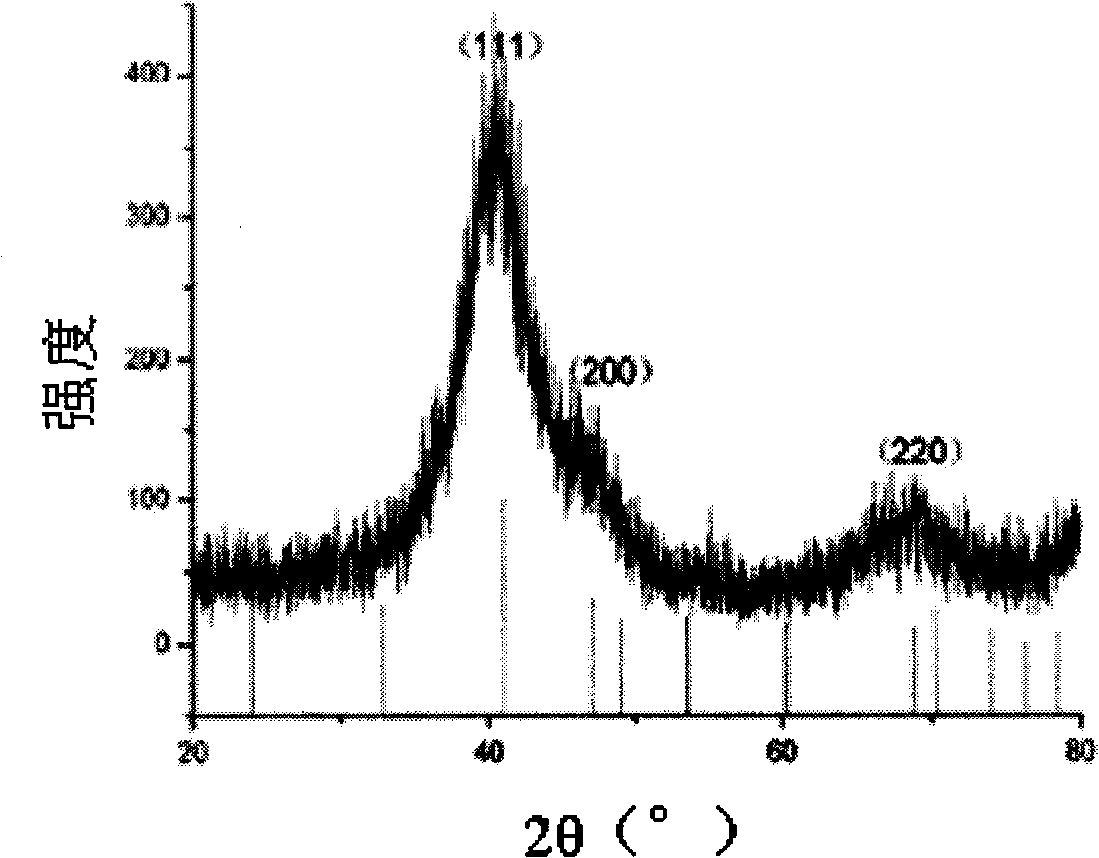

[0029] The preparation method of the iron-platinum alloy nanoparticles provided by the present embodiment is as follows: first take 0.05mol fourth generation (4G, its chemical structural formula is as follows: figure 1 Shown) take benzene ring as the polyamide-amine dendritic polymer of nucleus, add in 100ml tetraethylene glycol, at room temperature ultrasonic stirring makes it dissolve completely, is mixed with the templating agent solution that concentration is 0.5mol / L; Then Add 0.5mol of iron triacetylacetonate and 0.5mol of platinum diacetylacetonate into the above template solution; perform anaerobic operation and heat the reaction system under the protection of inert gas. 5 minutes; then continue to heat up, when the temperature rises to 200-220°C, keep warm for 5-10 minutes; then continue to heat up, when the temperature rises to 245-265°C, keep warm for 3-5 hours; the reaction is completed, naturally Cool to room temperature, centrifuge the reaction system, rinse the ...

Embodiment 2

[0034] The preparation method of this example is the same as that described in Example 1, except that the template used is 0.05mol of the fifth generation (5G, whose chemical structural formula is as follows: Figure 5 Shown) polyamide-amine dendrimers with benzene ring as the core.

[0035] Image 6 The transmission electron microscope (TEM) photograph of the iron-platinum alloy nanoparticles prepared for this embodiment shows that: this embodiment can obtain iron-platinum alloy nanoparticles with an average particle size of 10 nm, good dispersibility and no agglomeration.

Embodiment 3

[0037] The preparation method of this example is the same as that described in Example 1, except that the template used is 0.05mol of the sixth generation (6G, whose chemical structural formula is as follows Figure 7 Shown) polyamide-amine dendrimers with benzene ring as the core.

[0038] Figure 8 The transmission electron microscope (TEM) photograph of the iron-platinum alloy nanoparticles prepared for this embodiment shows that: this embodiment can obtain iron-platinum alloy nanoparticles with an average particle size of 10 nm, good dispersibility and no agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com