Method for one-step growth of carbon nanotube by taking carbon composite as catalyst

A technology of carbon nanotubes and composites, which is applied in the field of one-step growth of carbon nanotubes using carbon-containing composites as catalysts, can solve the problems of many preparation steps, large energy consumption, and complicated process, and achieve simplified preparation steps, tube The effect of uniform diameter and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 2.6172g Ni(NO 3 ) 2 ·6H 2 O and 1.1254g Al(NO 3 ) 3 9H 2O was added to 30ml deionized water to prepare a mixed salt solution, in which Ni 2+ The concentration is 0.3mol L -1 , Al 3+ The concentration is 0.1mol L -1 30ml of mixed alkali solution is prepared with 0.768g sodium hydroxide and 0.636g anhydrous sodium carbonate, wherein the concentration of sodium hydroxide is 0.64mol L -1 , the concentration of anhydrous sodium carbonate is 0.2molL -1 .

[0025] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature and mix them, vigorously rotate and stir for 2 minutes, centrifuge the obtained suspension, and run it at 4000 rpm for 5 minutes , and washed 5 times with water to obtain a precipitate.

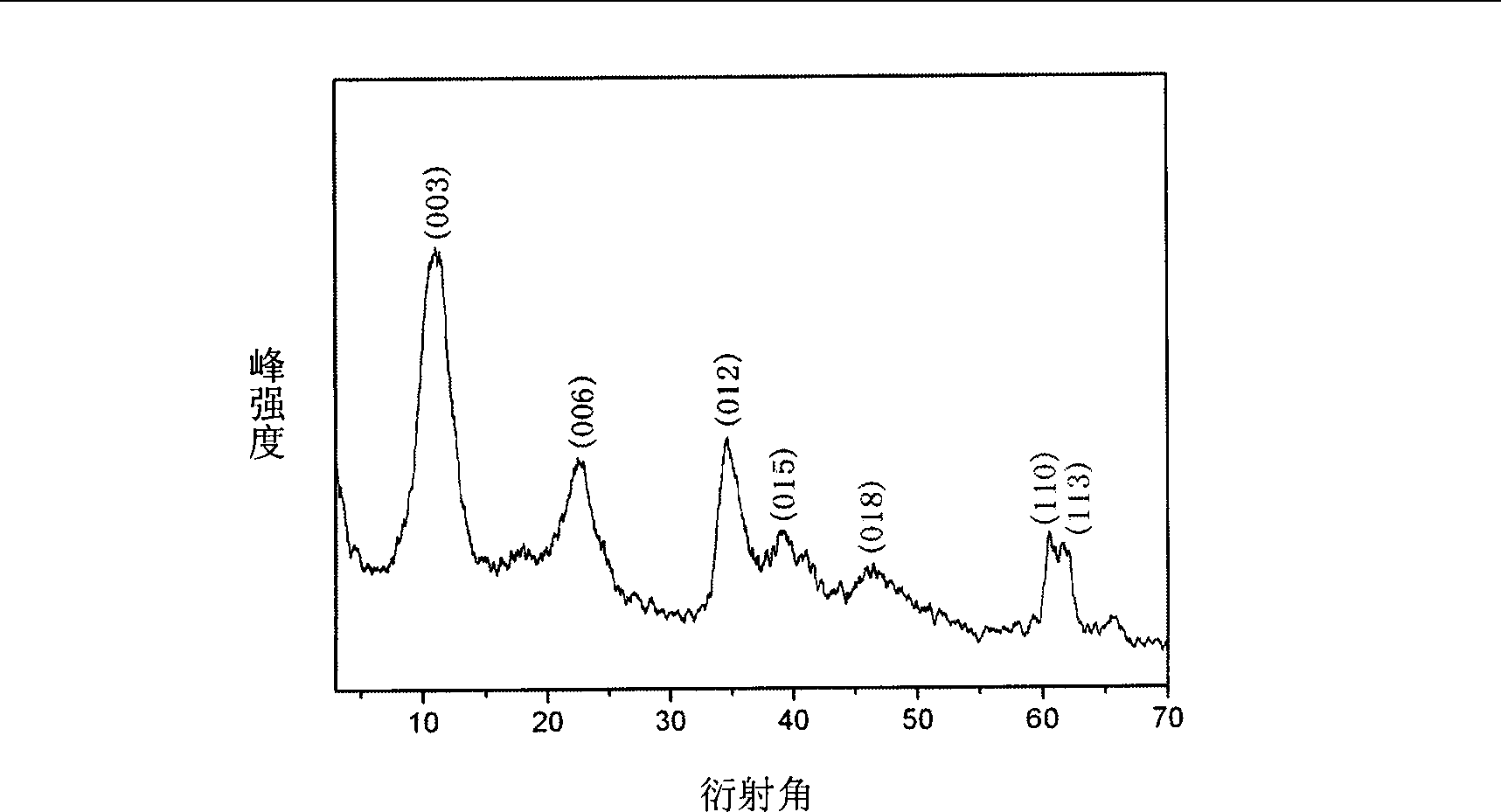

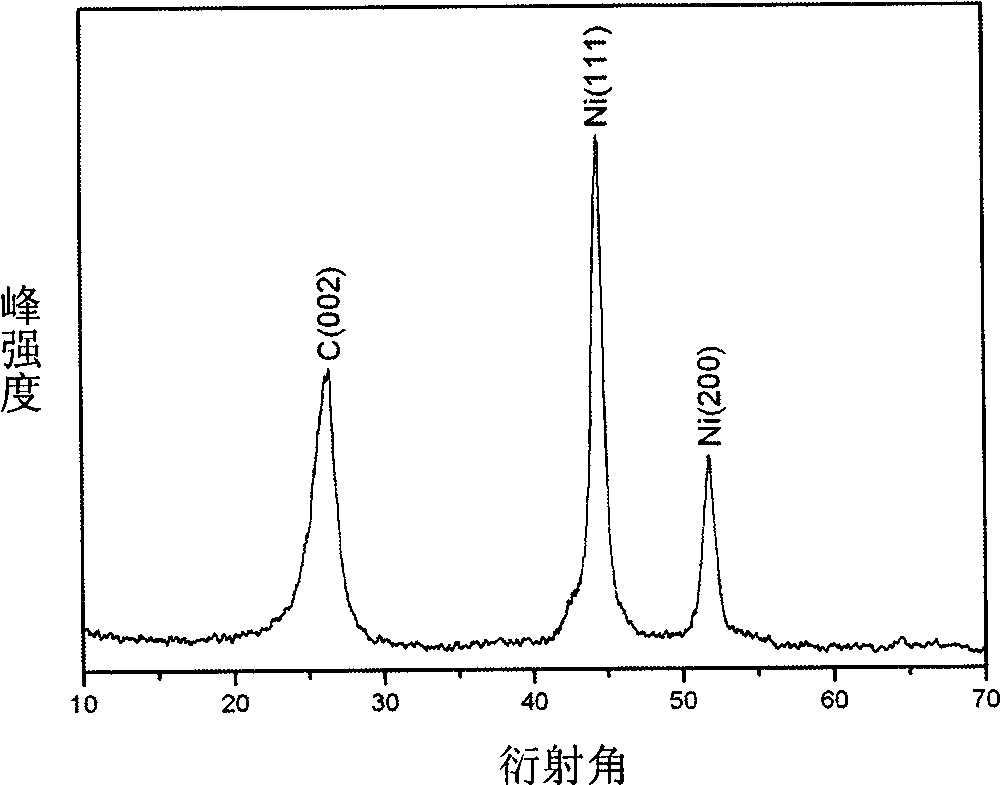

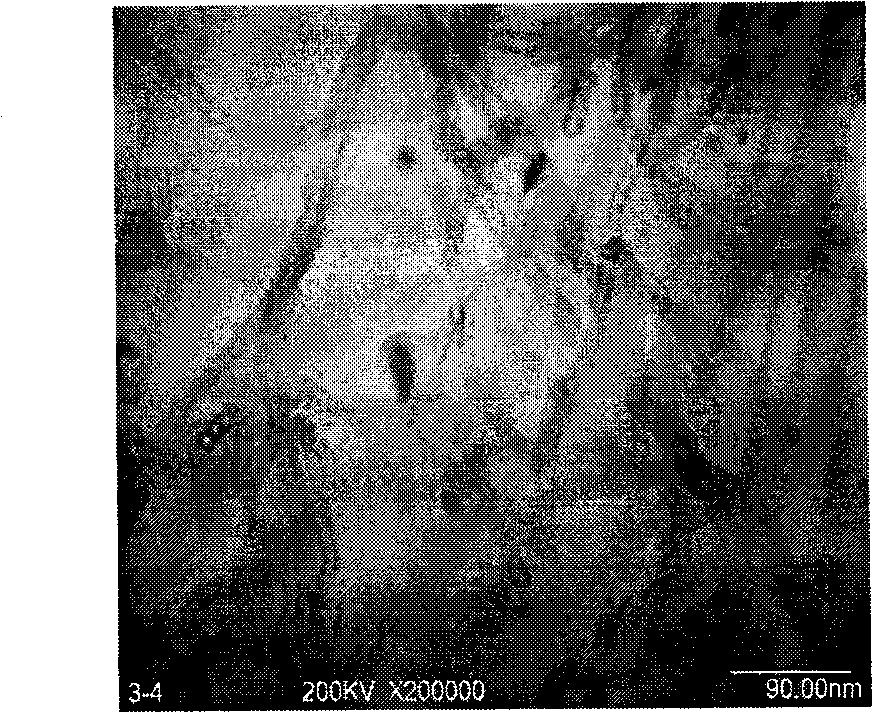

[0026] Dissolve 5.400g of glucose in 30ml of deionized water to prepare a solution, mix the prepared precipitate with the glucose solution, pour it into the reaction kettle, add wat...

Embodiment 2

[0028] 2.6193g Co(NO 3 ) 2 ·6H 2 O and 1.1254g Al(NO 3 ) 3 9H 2 O was added to 30ml deionized water to prepare a mixed salt solution, in which Co 2+ The concentration is 0.3mol L -1 , Al 3+ The concentration is 0.1mol L -1 30 milliliters of mixed alkaline solutions are prepared with 0.768g sodium hydroxide and 0.636g anhydrous sodium carbonate, wherein the concentration of sodium hydroxide is 0.64mol L -1 , the concentration of anhydrous sodium carbonate is 0.2mol L -1 .

[0029] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature and mix them, vigorously rotate and stir for 5 minutes, centrifuge the obtained suspension, and run it at 4000 rpm for 5 minutes , and washed 5 times with water to obtain a precipitate.

[0030] Dissolve 4.05g of glucose into 30ml of deionized water to prepare a solution, mix the obtained precipitate with the glucose solution, pour it into the reactio...

Embodiment 3

[0032] 5.814g Ni(NO 3 ) 2 ·6H 2 O and 3.75g Al(NO 3 ) 3 9H 2 O was added to 50ml deionized water to prepare a mixed salt solution, in which Ni 2+ The concentration is 0.4mol L -1 , Al 3+ The concentration is 0.2mol L -1 ; Prepare 50 milliliters of mixed alkaline solutions with 1.92g sodium hydroxide and 2.12g anhydrous sodium carbonate, wherein the concentration of sodium hydroxide is 0.96mol L -1 , the concentration of anhydrous sodium carbonate is 0.4mol L -1 .

[0033] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature and mix, vigorously rotate and stir for 3 minutes, centrifuge the obtained suspension, and run it at 4000 rpm for 5 minutes , and washed 4 times with water to obtain a precipitate.

[0034] Dissolve 20.54g of sucrose in 50ml of deionized water to prepare a solution, mix the prepared precipitate with the sucrose solution, pour it into the reaction kettle, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pipe diameter | aaaaa | aaaaa |

| Average pipe diameter | aaaaa | aaaaa |

| Average pipe diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com