Method for preparing cristobalite material by taking quartz crucible as raw material

A technology of quartz crucible and cristobalite, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve problems such as large energy consumption, high production cost, complex production process, etc., and achieve low production cost, simple production process, Highly economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

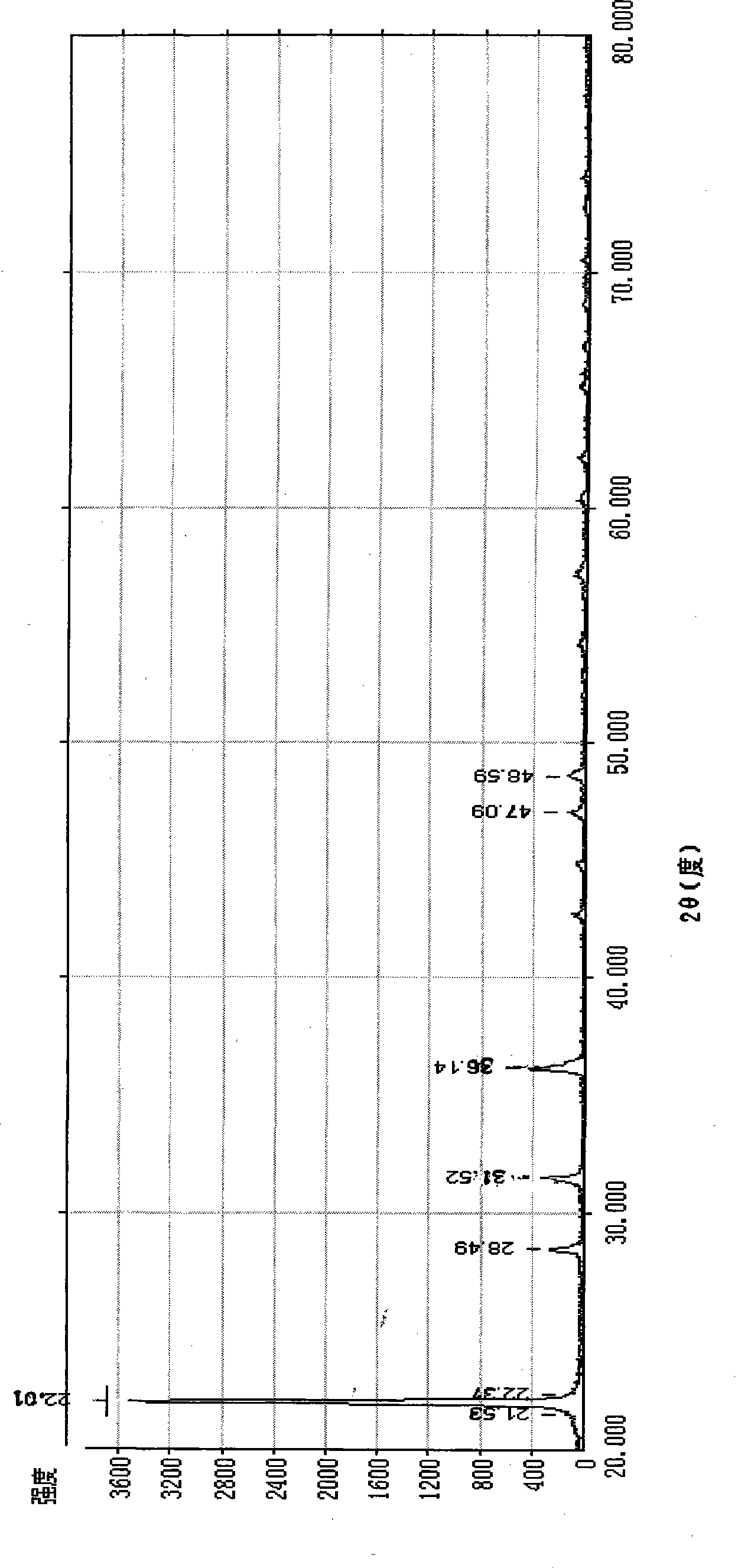

[0016] Take out the used quartz ceramic crucible from the silicon material factory. This quartz ceramic crucible has been used for polysilicon melting. The temperature of polysilicon melting is 1500-1550 ° C. After the crucible is cooled, it is polished with a grinding wheel to remove surface impurities, and then rinsed with tap water. After drying, it is broken into cristobalite blocks of 10-50 mm. The composition (mass percentage) of the cristobalite material obtained by this method is shown in Table 1, which shows that this is a very high-purity quartz material. The X-ray powder diffraction pattern of cristobalite is shown in figure 1 , showing that the crystal phase composition in cristobalite material is mainly cristobalite phase.

[0017] Table 1

[0018] SiO 2 Al 2 o 3 Fe 2 o 3 Li 2 o Na 2 o K 2 o MgO TiO 2 CuO CaO >99.8 0.08 0.02 <0.01

Embodiment 2

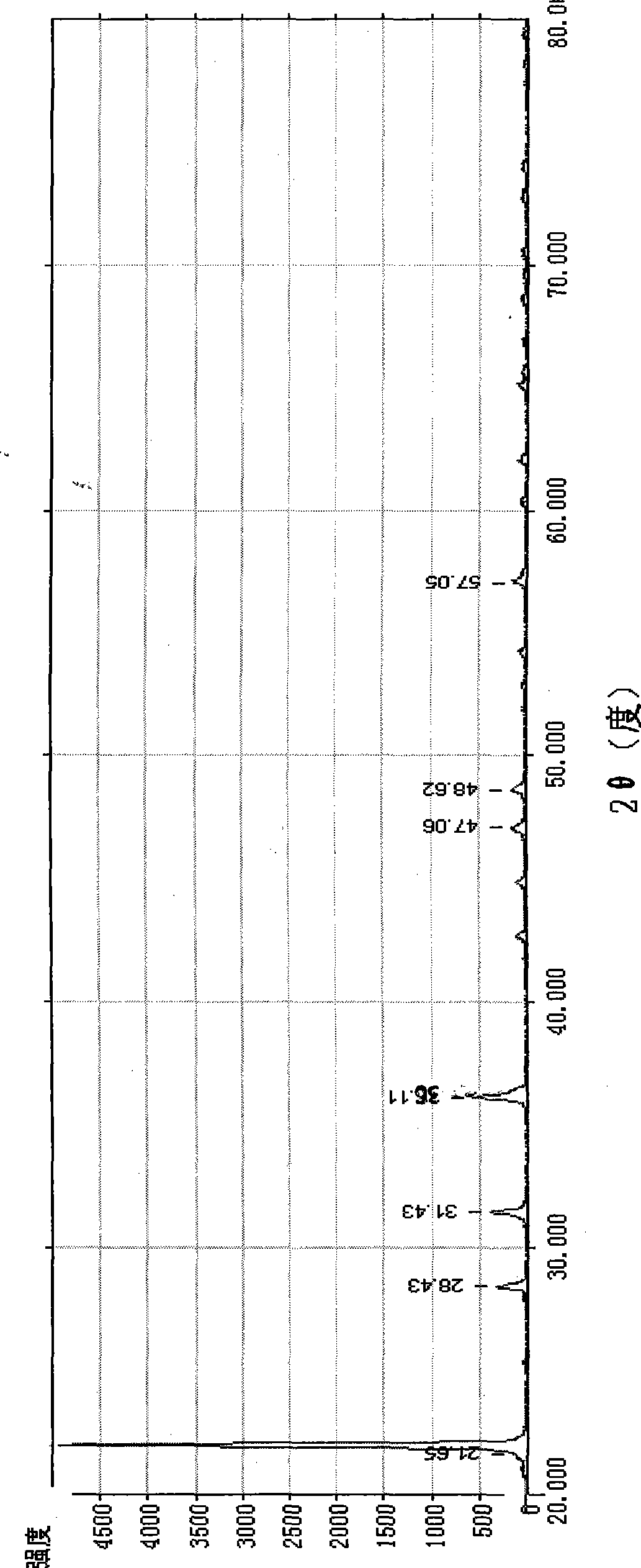

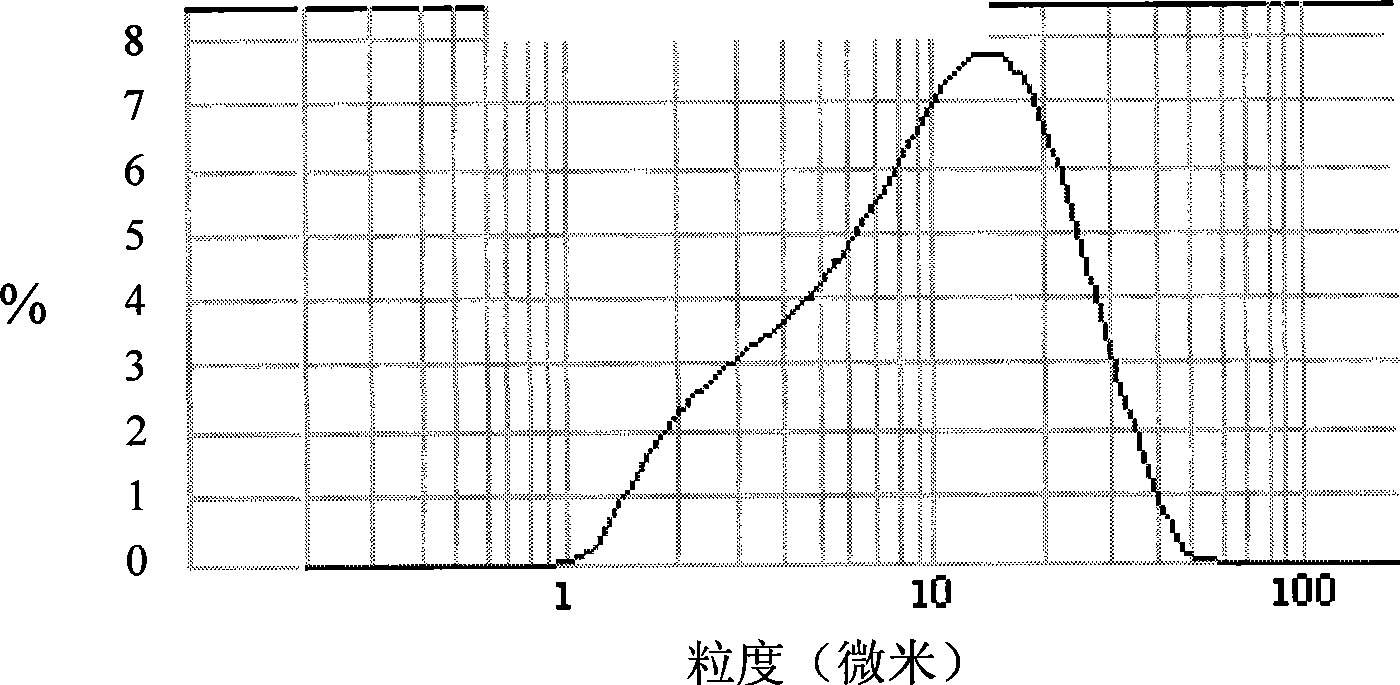

[0020] Take out the used quartz ceramic crucible from silicon material factory, this quartz ceramic crucible has been used for polysilicon melting, the temperature of polysilicon melting is 1500~1550 ℃. After the crucible pieces are cooled, they are washed with tap water, and then soaked in hydrofluoric acid solution. The amount of hydrofluoric acid used in 1 ton of water is 200 liters. After soaking at room temperature for 2 days, the surface of the crucible piece changed from gray to white, and the crucible was taken out and cleaned with tap water. Break the washed white crucible piece, grind it with a ball mill with a corundum medium, and obtain cristobalite powder with a certain particle size distribution after the slurry is dried. The composition (mass percentage) of cristobalite powder obtained by this method is shown in Table 2. Due to the use of corundum media in the grinding process, the alumina content in the powder increased to some extent, but due to the treatment ...

Embodiment 3

[0024] Take out the used quartz ceramic crucible from the silicon material factory, this quartz ceramic crucible has been used for polysilicon melting, the temperature of polysilicon melting is 1500~1550 ℃. After the crucible pieces are cooled, they are washed with tap water, and then soaked in ammonium bifluoride solution. The amount of ammonium bifluoride in 1 ton of water is 100 kg. After immersing at room temperature for 2 days, the gray on the surface of the crucible piece turned white, and the crucible piece was taken out and cleaned with tap water. The dry process is adopted, that is, the dried white crucible pieces are crushed, and then ground in a corundum-lined and medium ball mill, and cristobalite powder with a certain particle size distribution is obtained after the product is classified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com