Method of baking ceramsite by using sludge

A sludge ceramsite and sludge technology, which is applied in the fields of dewatering/drying/concentrating sludge treatment, application, clay products, etc., can solve the problems of aggravation, atmospheric environmental pollution, unbearable sludge incineration, etc., and achieve low production costs. , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 2) Preparation of raw meal balls

[0039]The sludge with a water content of 35-30% is stored for 3-5 days to reduce the water content of the sludge to 25-20%, and is pressed into raw pellets by a press, and the working pressure of the press is 58.0 ~62.0 MPa. The shape and size of the sludge raw pellets can be designed according to the overall specifications of the press.

[0040] 3) Sludge raw pellet storage

[0041] After the sludge raw meal pellets are stored for 3-5 days, the water content of the sludge is further reduced to 20-18%, which creates conditions for the sludge raw pellets to be fired into ceramsite.

[0042] 4) Sludge ceramsite firing

[0043] Put the stored sludge raw meal balls in the ceramsite roaster, first heat the sludge raw meal balls from room temperature to 190-200°C at a constant rate, keep at 190-200°C for 55-60min, and then Heat at a rate of ~3°C / min to the maximum temperature of 1000-1100°C, keep at the maximum temperature for 55-60 minu...

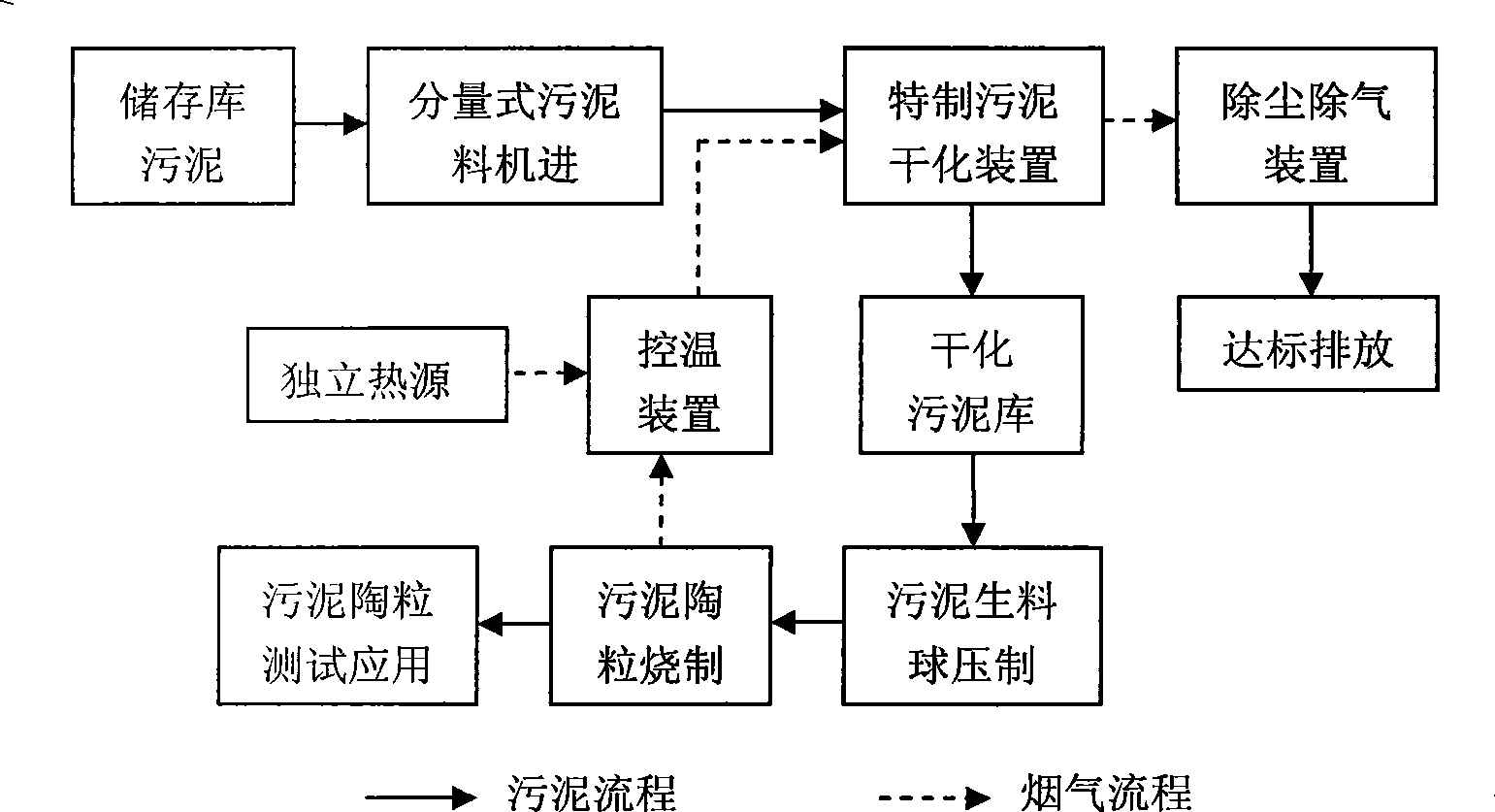

Embodiment 1

[0045] The moisture content of the sludge after mechanical dehydration in Changzhou Sewage Treatment Plant is 75%. After the sludge has been pretreated, the moisture content has been reduced to 73%. The sludge is fed into the The 28m special sludge drying device carries out the drying process. The heat source for sludge drying comes from an independent heat source, and the drying temperature is 450°C. After a period of drying process, the moisture content of the sludge drops to 40%. The volume is reduced to less than one-third.

[0046] After a period of drying of the sludge, the moisture content will drop to 28% after being stacked for 5 days. The sludge with a moisture content of 28% is pressed into a short columnar sludge raw pellet in a special press with a pressure of 58.0MPa. The moisture content of the sludge raw pellets dropped to 22% after being stored for 3 days.

[0047] The stored sludge raw meal balls are roasted in the sintering furnace for sludge ceramsite. Fi...

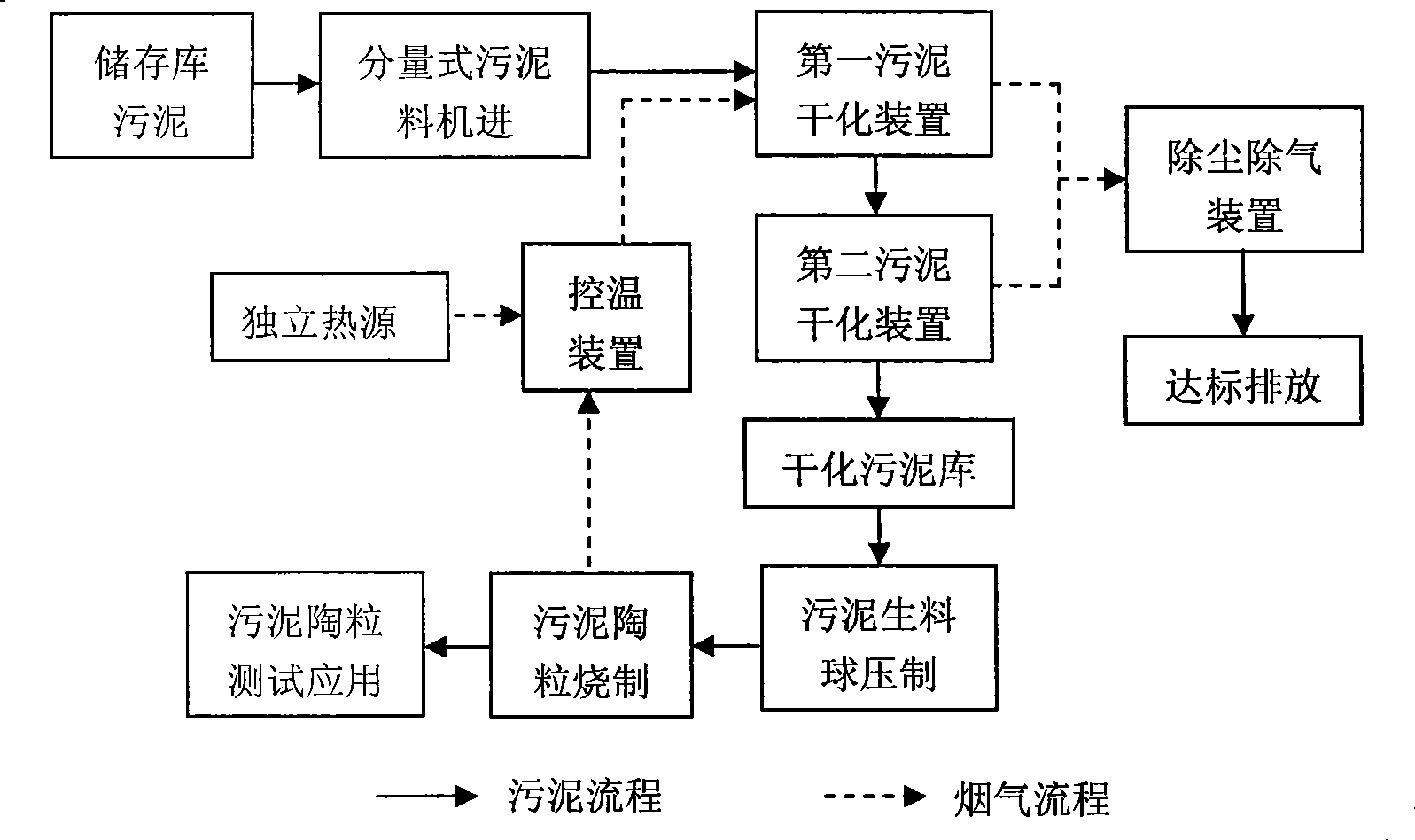

Embodiment 2

[0051] After mechanical dehydration, the sludge in Jiangyin Sewage Treatment Plant has a moisture content of 78%, and after three days of stacking, the moisture content has dropped to 75%. The sludge is fed into a 1.8m-diameter, long The first stage of drying is carried out in the first special sludge drying device with a diameter of 22m. After the first stage of drying, the sludge is sent to the special sludge dryer with a diameter of 1.6m and a length of 20m through a screw conveyor. The second stage of drying is carried out in the chemical plant. The heat source of sludge drying comes from the waste heat of the flue gas of the thermal power plant. more than two-thirds.

[0052] The moisture content of sludge after two-stage drying will drop to 30% after being stacked for 3 days. The sludge with a water content of 30% is pressed into sludge raw meal pellets in a special press with a pressure of 60.0 MPa, and the shape of the sludge raw meal pellets is a short cylindrical sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com