Colored curable resin composition, colored pattern forming method, colored pattern, method for manufacturing color filter, liquid crystal display element

A technology of curable resin and coloring pattern, which is applied in the direction of optical components, photoplate making process of pattern surface, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

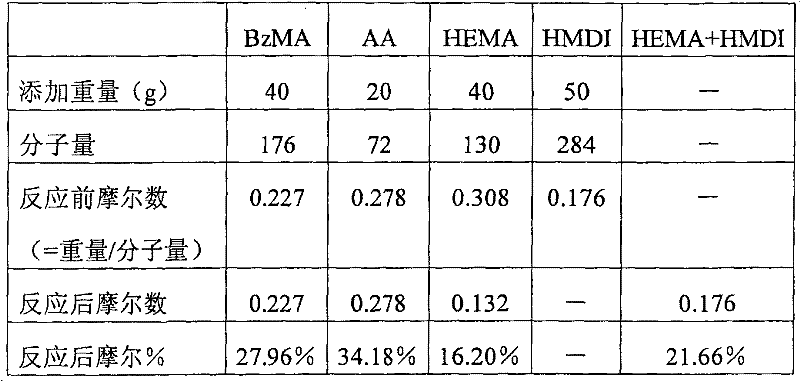

preparation example Construction

[0128] As the preparation method of titanium black, there is a method of heating and reducing the mixture of titanium dioxide and metallic titanium under a reducing atmosphere (Japanese Patent Application No. 49-5432). The method of reduction in reducing atmosphere (JP-A-57-205322), the method of reducing titanium dioxide or titanium hydroxide at high temperature in the presence of ammonia (JP-A-60-65069, JP-A-61-201610 ), a method of attaching a vanadium compound to titanium dioxide or titanium hydroxide and reducing it at high temperature in the presence of ammonia (JP-A-61-201610), etc., but these methods are not limited.

[0129] Examples of commercially available titanium black include titanium black 10S, 12S, 13R, 13M, and 13M-C manufactured by Mitsubishi Materials.

[0130] As examples of other black pigments, nigrosine, iron oxide-based black pigments, and three-color organic pigments of red, green, and blue can be mixed and used as black pigments.

[0131] In additio...

Embodiment 1

[0398] Components of the following compositions were mixed to prepare a pigment dispersion.

[0399] [Pigment dispersion]

[0400] ·Pigment (a)

[0401] C.I. Pigment Red 254 5 parts

[0402] C.I. Pigment Red 177 5 parts

[0403] ·Dispersion resin

[0404] Byk-161 by Bitsuku Chemi Co., Ltd. (active ingredient: 30 13.3 parts by mass%)

[0405] ·(b) Solvent

[0406] Propylene glycol monomethyl ether acetate 32.7 parts

[0407] In addition, the following components were mixed separately to prepare a transparent resist solution.

[0408] [Composition of transparent resist solution]

[0409] ・(c) Binder resin

[0410] 2.0 parts of acrylic resin (c1) represented by the following formula (6)

[0411] 2.0 parts of acrylic resin (c2) (A) shown in Table 1

[0412] ·(c3) Monomer

[0413] Dipentaerythritol hexaacrylate 4.0 parts

[0414] ·(d) Photopolymerization initiator

[0415] 0.4 parts of 2-(2-chlorophenyl)-4,5-diphenylimidazole dimer

[0416] 0.2 parts of 4,4'-bis(dieth...

Embodiment 2~4

[0447] Except having changed the binder resin (c2) in Example 1 into the compound shown in Table 2, it carried out similarly to Example 1, prepared the composition for coloring pattern formation, and evaluated it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com